Cobweb-like structural material based on single-walled carbon nanotubes and preparation method of material

A single-wall carbon nanotube and structural material technology, applied in the field of nanomaterials, can solve the problems of high production cost and low output, and achieve the effects of low cost, high mechanical properties, excellent electrical conductivity and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

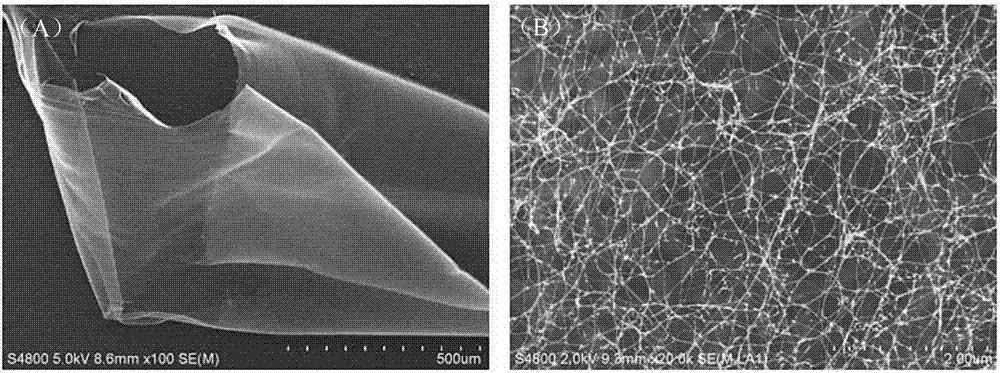

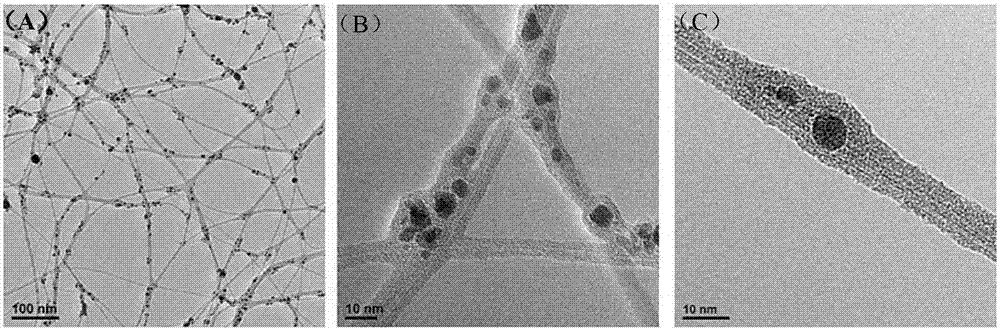

[0039] In this embodiment, the substrate for preparing the spider web-like structure material based on single-walled carbon nanotubes (SWCNTs) is a copper sheet. A floating catalyst chemical vapor deposition (CVD) method was used. Specifically as follows: Ferrocene (Fe(C 5 h 5 ) 2 ) Catalyst is placed in the porcelain boat that is bonded with iron sheet, and porcelain boat is placed in the upstream area in the quartz tube of CVD furnace, and the base is placed in the downstream area of quartz tube; After the quartz tube is closed, lead into argon gas with the flow rate of 500 sccm for 30 minutes to exhaust Despite the air inside, heat the quartz tube to 950°C at a heating rate of 15°C / min, and then use a magnet to move the porcelain boat containing the ferrocene catalyst to an area with a temperature of 80°C for sublimation; at a flow rate of 10 sccm Introduce high-purity CH 4 gas, the reaction process was maintained for 30 minutes, and the introduction of CH was stopped...

Embodiment 2

[0041] In this embodiment, the substrate for preparing the spider web-like structure material based on single-walled carbon nanotubes (SWCNTs) is a copper microgrid. A floating catalyst chemical vapor deposition (CVD) method was used. Specifically as follows: Ferrocene (Fe(C 5 h 5 ) 2 ) The catalyst is placed in a porcelain boat glued with iron sheets, the porcelain boat is placed in the upstream area of the quartz tube of the CVD furnace, and the substrate is placed in the downstream area of the quartz tube. After the quartz tube is closed, flow argon gas at a flow rate of 500 sccm for 30 minutes to exhaust the air in the tube; heat the quartz tube to 950 °C at a heating rate of 15 °C / min, and then use a magnet to place the ferrocene catalyst in the porcelain boat Move to an area with a temperature of 60°C for sublimation; pass high-purity CH at a flow rate of 10 sccm 4 gas, the reaction process was maintained for 10 minutes, and the introduction of CH was stopped. 4...

Embodiment 3

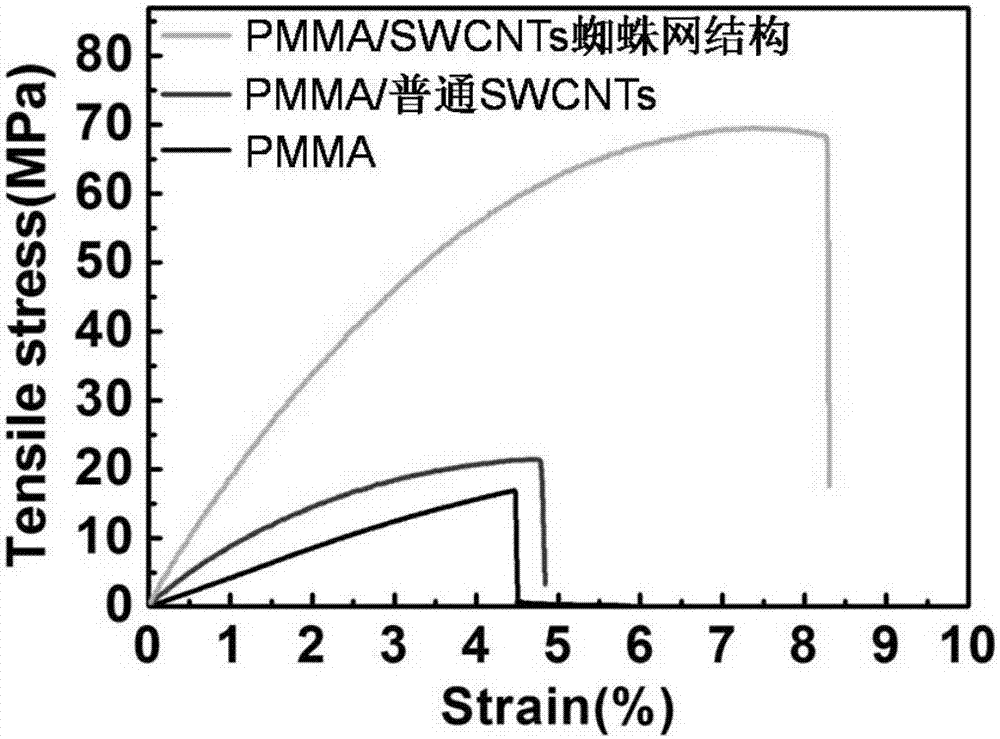

[0043] In this embodiment, the substrate for preparing the spider web-like structure material based on single-walled carbon nanotubes (SWCNTs) is a polymethyl methacrylate (PMMA) film (length 80 mm, width 20 mm, thickness 0.5 mm). A floating catalyst chemical vapor deposition method was used. Specifically as follows: Ferrocene (Fe(C 5 h 5 ) 2 ) Catalyst is placed in the porcelain boat that is stuck with iron sheet, and porcelain boat is placed in the upstream area in the quartz tube of CVD furnace, and PMMA substrate is placed in the downstream area of quartz tube, after the quartz tube is closed, feed argon gas with the flow velocity of 500sccm for 30 minutes or more. Exhaust the air in the tube; heat the quartz tube to 950°C at a heating rate of 15°C / min; then use a magnet to move the porcelain boat containing the ferrocene catalyst to an area with a temperature of 120°C for sublimation; at a flow rate of 10sccm Introduce high-purity CH 4 gas, the reaction process was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com