Totally-enclosed storage and pretreatment device for co-treating industrial sludge with cement kiln

A pretreatment device and co-processing technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of occupying large land resources, waste of calorific value, high disposal cost, etc. problem, to avoid waste of cultivated land resources and increase calcium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

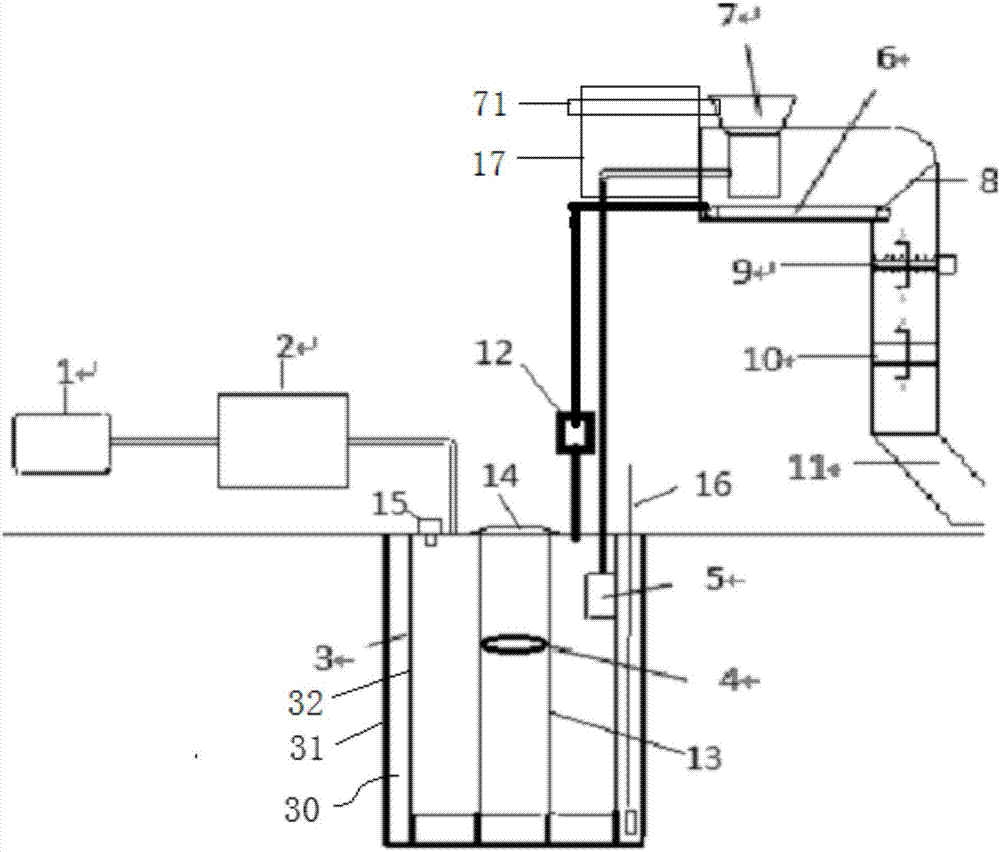

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the present invention discloses a fully enclosed storage and pretreatment device for co-processing industrial sludge in cement kilns, including pump 1, pulverizer 2, underground silo 3, fine stone concrete pump 5, first conveyor belt 6, heat preservation and vibration Sieve 7, roller 10, second conveyor belt 11, air extractor 12, heat spreader 17, sludge treatment agent conveyor belt 71, high-energy ion generator and the mixing bucket that is provided with stirring shaft 9 and roller 10, and described pump 1 The discharge end of the pulverizer 2 is connected to the feed end of the pulverizer 2, the discharge end of the pulverizer 2 is connected to the underground silo 3, the feed end of the fine stone concrete pump 5 extends in the underground silo 3, and the fine stone concrete pump 5 The discharge end of the discharge end extends ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com