Novel formula battery and preparation method thereof

A formula and battery technology, which is applied in the construction of secondary batteries, lead-acid batteries, lead-acid batteries, etc., can solve the problems of elastic fatigue of the separator, affecting the service life of the battery, and large power consumption, so as to reduce the number of water additions and effectively provide The effect of less water consumption for energy and reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

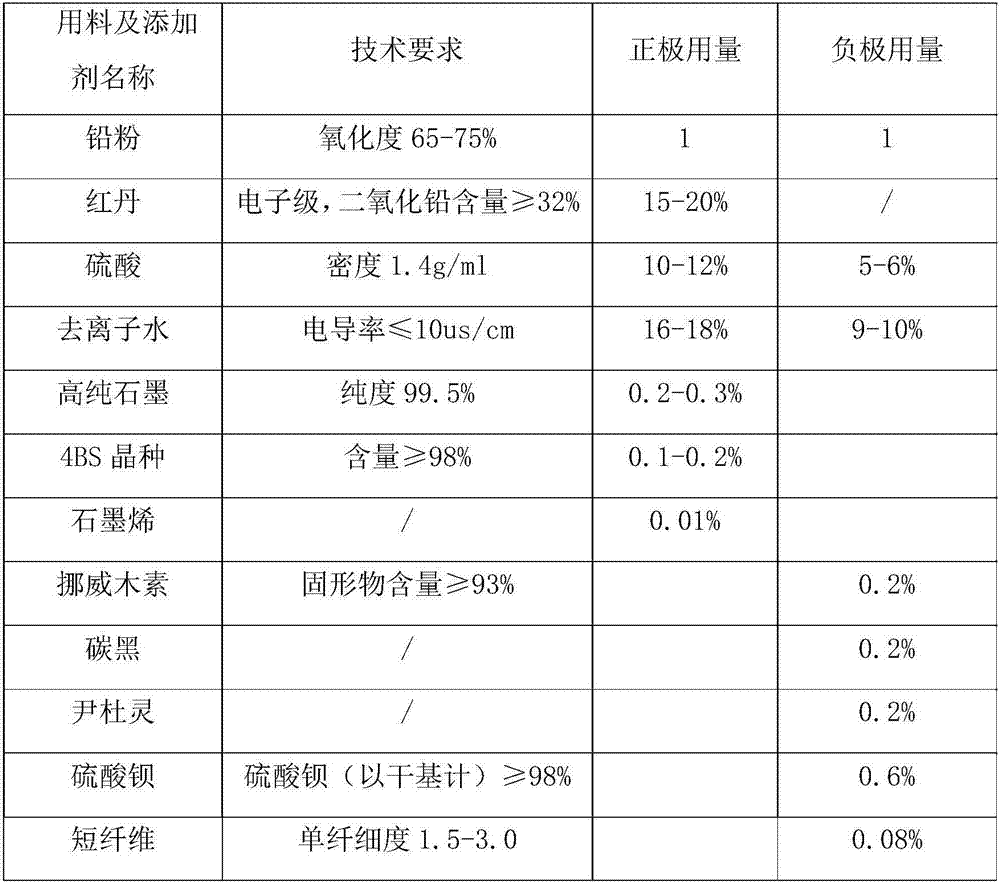

[0044] In the new formula battery provided by this embodiment, additive formulas of different proportions are added to the positive and negative plates. ene, high-purity graphite.

[0045] Add 1 part of lead powder with an oxidation degree of 65% to the positive plate, electronic grade, 15% of red lead with lead dioxide content ≥ 32%, 10% of sulfuric acid, 16% of deionized water with conductivity ≤ 10us / cm, High-purity graphite 0.2%, 4BS seed crystal 0.1%, graphene 0.01%.

[0046] Add 1 part of lead powder with an oxidation degree of 65% to the positive plate, 5% of sulfuric acid, 9% of deionized water with a conductivity of ≤10us / cm, 0.2% of Norway lignin with a solid content of ≥93%, and 0.2% of carbon black. %, Yin Duling 0.2%, barium sulfate 0.6%, short fiber 0.08%.

[0047] The high-purity graphite is graphite with a purity of 99.5%, and the sulfuric acid is sulfuric acid with a density of 1.4 g / ml.

[0048] The present invention also provides its preparation method fo...

Embodiment 2

[0060] In the new formula battery provided by this embodiment, additive formulas of different proportions are added to the positive and negative plates. ene, high-purity graphite.

[0061] Add 1 part of lead powder with an oxidation degree of 75% to the positive plate, electronic grade, red lead 15-20% with lead dioxide content ≥ 32%, sulfuric acid 12%, deionized water 18 with conductivity ≤ 10us / cm %, high-purity graphite 0.3%, 4BS seed crystal 0.2%, graphene 0.01%.

[0062] Add 1 part of lead powder with an oxidation degree of 65-75% to the positive plate, 6% of sulfuric acid, 10% of deionized water with a conductivity of ≤10us / cm, 0.2% of Norwegian lignin with a solid content of ≥93%, and carbon Black 0.2%, Yin Duling 0.2%, barium sulfate 0.6%, short fiber 0.08%.

[0063] The high-purity graphite is graphite with a purity of 99.5%, and the sulfuric acid is sulfuric acid with a density of 1.4 g / ml.

[0064] The present invention also provides its preparation method for th...

Embodiment 3

[0076] In the new formula battery provided by this embodiment, additive formulas of different proportions are added to the positive and negative plates. ene, high-purity graphite.

[0077] Add 1 part of lead powder with an oxidation degree of 70% to the positive plate, electronic grade, red lead 15-20% with lead dioxide content ≥ 32%, sulfuric acid 11%, deionized water with conductivity ≤ 10us / cm 17 %, high-purity graphite 0.25%, 4BS seed crystal 0.15%, graphene 0.01%.

[0078] Add 1 part of lead powder with an oxidation degree of 70% to the positive plate, 5.5% of sulfuric acid, 9.5% of deionized water with a conductivity of ≤10us / cm, 0.2% of Norway lignin with a solid content of ≥93%, and 0.2% of carbon black. %, Yin Duling 0.2%, barium sulfate 0.6%, short fiber 0.08%.

[0079] The high-purity graphite is graphite with a purity of 99.5%, and the sulfuric acid is sulfuric acid with a density of 1.4 g / ml.

[0080] The present invention also provides its preparation method f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com