Button paint, button paint mixture, mirror-like metal button and preparation technology thereof

A technology of mirror surface metal and preparation process, which is applied in the field of clothing production, and can solve problems such as hindering the large-scale application of the market, poor performance such as washing resistance, dry cleaning and ironing resistance, and the inability to realize product color diversity and market diversification needs. , to overcome the problems that hinder the large-scale production and application of the market, meet the diversified needs of the market, and achieve the effect of rich and diverse colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

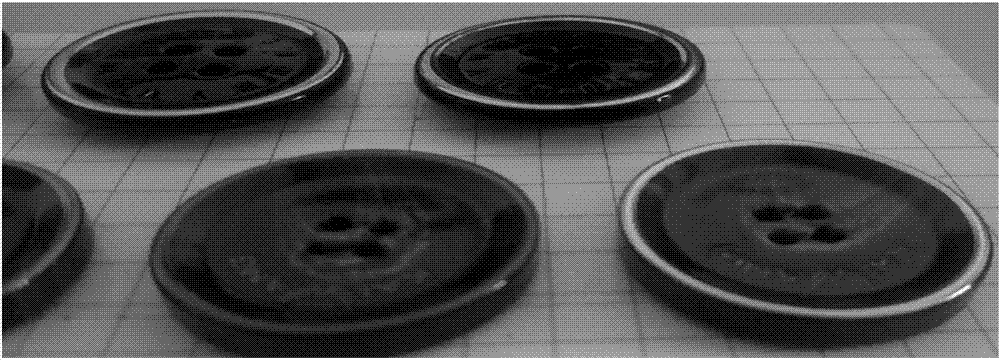

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation technology of mirror surface metal button, comprises the following steps:

[0044] a) Carrying out bronzing treatment to button blank material, obtains bronzing button;

[0045] b) spray film material to the bronzing button to obtain a mirror metal button;

[0046] The film material includes the button paint described in the above technical solution or the paint mixture described in the above technical solution.

[0047] According to the invention, the hot stamping treatment is carried out on the button stock to obtain the hot stamping buttons.

[0048] In the present invention, the type of the button blank is not particularly limited, and it can be a button blank well known in the art, such as a resin button, a natural shell button, a plastic nylon button or an ABS button. Among them, resin buttons are artificially synthesized buttons, adding accelerators and various functional accessories (such as pearl effec...

Embodiment 1

[0061] 1.1 Preparation of film material

[0062] Polyacrylic acid resin liquid 23% (provided by Guangzhou Zuoli New Material Co., Ltd., model is ZL-506, solid content is 50%), dibutyl phthalate 0.16%, tricresyl phosphate 0.16%, melamine formaldehyde resin Liquid 2.20% (provided by Beijing Jintong Letai Chemical Products Co., Ltd., CAS number is 9003-08-1, solid content is 50%), butyl acetate 33%, butanol 13.5%, toluene 13.5%, alcohol 2.8 %, the pigment is added to 100% (provided by the manufacturer of Dongguan Jinyou Chemical Technology Co., Ltd., the model is ZS series light-resistant color essence); the above-mentioned components are mixed evenly, filtered, and the paint is obtained.

[0063] Mix the above paint, isocyanate monomer curing agent, diacetone alcohol and toluene diluent (the mass ratio of diacetone alcohol:toluene is 1:1) with a mass ratio of 3:1:2.5 to form a paint mix material to obtain film material.

[0064] 1.2 Preparation of buttons

[0065] Use a polis...

Embodiment 2

[0072] 1.1 Preparation of film material

[0073]Polyacrylic acid resin liquid 24.5% (provided by Guangzhou Zuoli New Material Co., Ltd., model is ZL-506, solid content is 50%), dibutyl phthalate 0.17%, tricresyl phosphate 0.17%, melamine formaldehyde resin Liquid 2.30% (provided by Beijing Jintong Letai Chemical Products Co., Ltd., CAS number is 9003-08-1, solid content is 50%), butyl acetate 34%, butanol 13.8%, toluene 13.8%, alcohol 3 %, the pigment is added to 100% (provided by the manufacturer of Dongguan Jinyou Chemical Technology Co., Ltd., the model is ZS series light-resistant color essence); the above-mentioned components are mixed evenly, filtered, and the paint is obtained.

[0074] Mix the above paint, isocyanate monomer curing agent, diacetone alcohol and toluene diluent (the mass ratio of diacetone alcohol:toluene is 1:1) with a mass ratio of 3.5:1:3 to form a paint mix material to obtain film materials.

[0075] 1.2 Preparation of buttons

[0076] Use a polis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com