Composite solid electrolyte material without adding lithium salt as well as electrolyte membrane and preparation method thereof

A technology of solid electrolyte membrane and solid electrolyte, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc. It can solve the problems of polymer amorphization, affecting the working temperature range of electrolytes, and reducing the melting point of polymers, so as to achieve high safety Sexuality, easy processing and transportation, and the effect of improving energy density

Inactive Publication Date: 2017-11-14

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF3 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the addition of lithium salt is beneficial to improve the ionic conductivity of the electrolyte, the crosslinking or coupling reaction between the lithium salt and the polymer will make the polymer amorphous, thereby reducing the melting point of the polymer, which in turn affects the working temperature range of the electrolyte.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Login to View More

Abstract

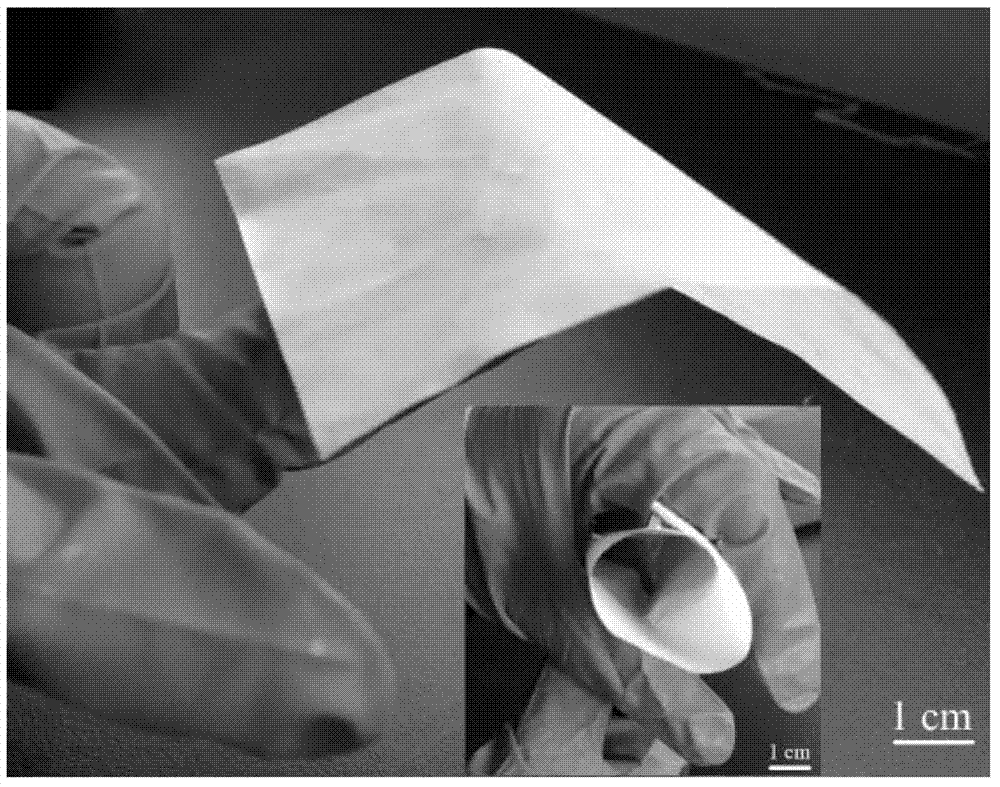

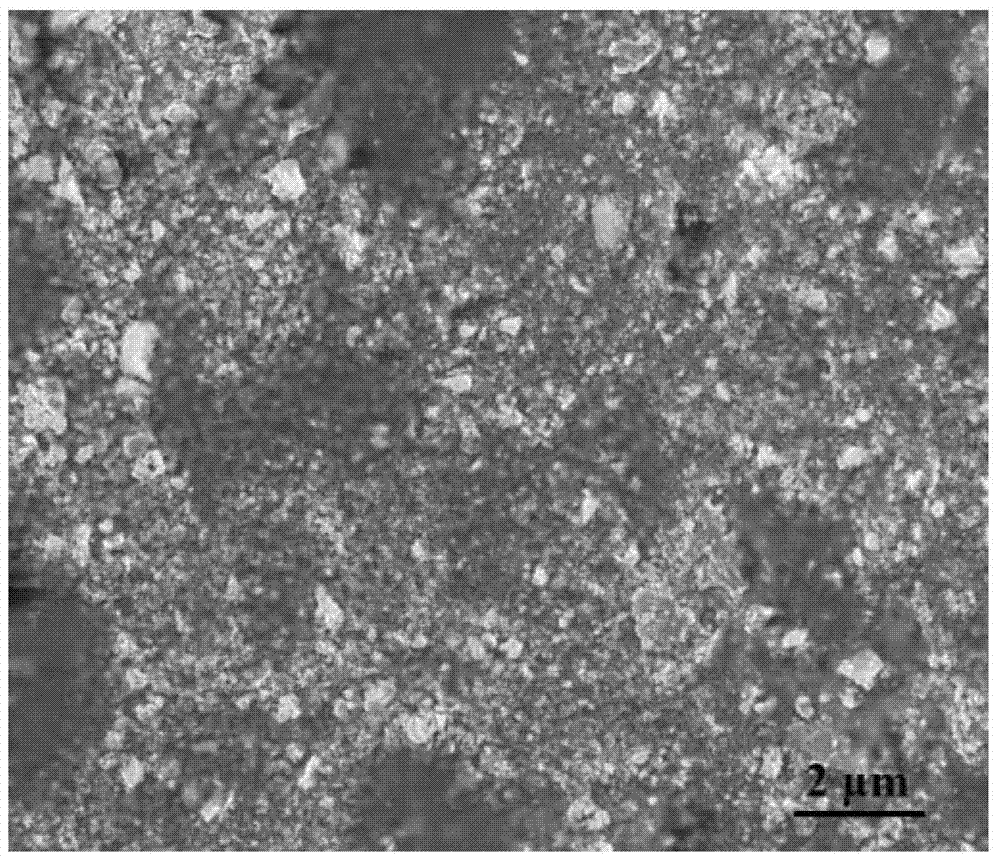

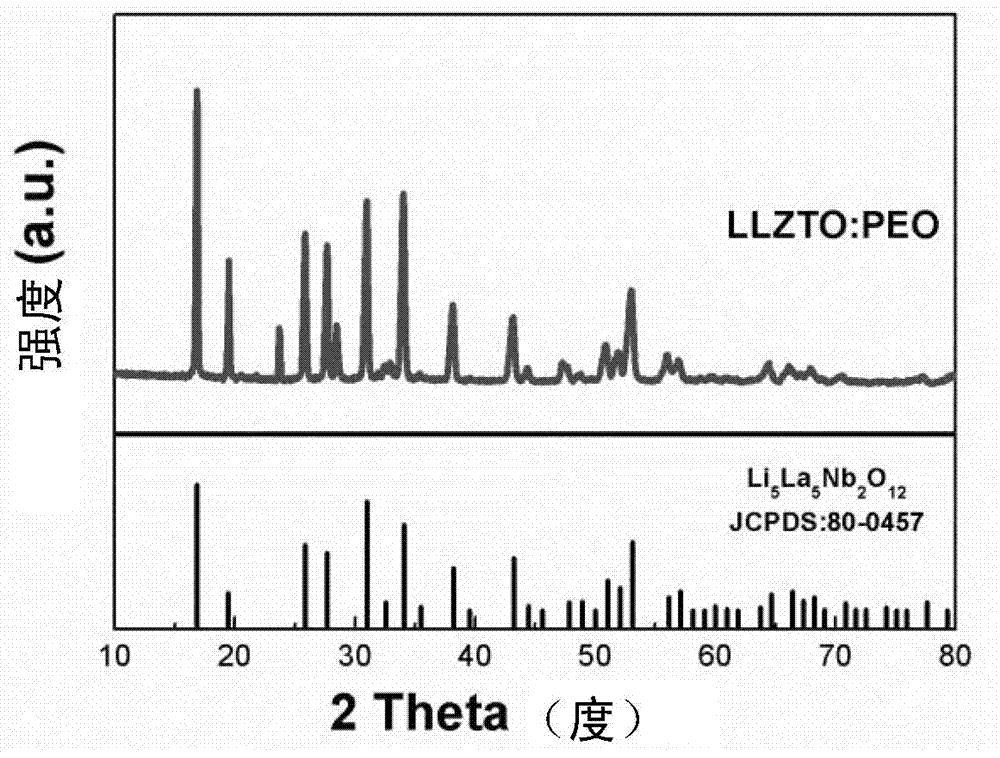

The invention relates to a composite solid electrolyte material without adding lithium salt as well as an electrolyte membrane and a preparation method thereof. The composite solid electrolyte material comprises a polymer matrix material and a fast ion conductor powder material; the chemical formula of the fast ion conductor powder material is Li7-xLa3Zr2-xMxO12, wherein M is at least one of Al, Ta, Nb, W, Ga, Y and Te, and x is greater than or equal to 0 and less than or equal to 1; the composite solid electrolyte material contains no lithium salt. Compared with other composite solid electrolyte, the composite solid electrolyte material disclosed by the invention has the greatest difference that no lithium salt in any form is added in the polymer, and ionic conductivity at room temperature under the condition can reach 10<-4>S cm<-1>. The composite solid electrolyte membrane disclosed by the invention has good cycle performance and rate capability at room temperature of 25 DEG C and 60 DEG C when being applied to a lithium secondary battery.

Description

Lithium-free salt-added composite solid-state electrolyte material, electrolyte membrane and preparation method thereof technical field The invention relates to a high ion conductance composite solid electrolyte material, an electrolyte membrane and a preparation method thereof, which can be applied to an all-solid lithium secondary battery without adding lithium salt, and belongs to the technical field of batteries. Background technique As a new generation of green high-energy batteries, lithium secondary batteries have the advantages of small weight, high energy density, long cycle life, high working voltage, no memory effect, and no environmental pollution. They have been widely used in portable batteries such as mobile phones, notebook computers, and cameras. In electronic equipment, it is also the preferred power source for electric vehicles and hybrid electric vehicles in the future, with broad application prospects and huge economic benefits. The electrolyte materi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M10/0565H01M10/058

CPCH01M10/0565H01M10/058Y02E60/10Y02P70/50

Inventor 郭向欣张静娴郭睿涵赵宁李忆秋

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com