A kind of industrial synthetic sulfur gypsum and preparation method thereof

A technology of sulfur gypsum and gypsum, which is applied in chemical instruments and methods, preparation of alumina/hydroxide, calcium/strontium/barium sulfate, etc., can solve problems affecting the performance of cement and achieve good economic and social benefits , Reduce production cost, moderate hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

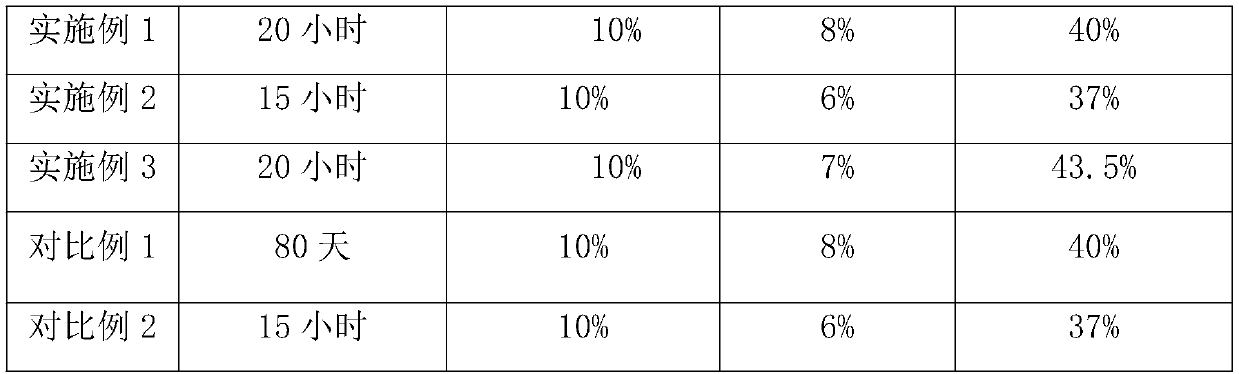

Embodiment 1

[0013] Take 40kg of fluorine gypsum, 30kg of titanium gypsum and 30kg of other industrial gypsum and mix them evenly; then add glauberite gypsum, the content of sodium sulfate in the glauberite gypsum accounts for 0.2% of the total gypsum mass, and carry out the reaction, controlling the temperature at 60°C, industrial Gypsum crystallization reaction.

[0014] Take the above-mentioned crystalline gypsum for secondary crushing and stirring, and pulverize it into granules.

Embodiment 2

[0016] Take 20kg of fluorine gypsum and 80kg of titanium gypsum and mix them evenly; then add glauberite gypsum, the content of sodium sulfate in the glauberite gypsum accounts for 0.2% of the total gypsum mass, and carry out the reaction.

[0017] Take the above-mentioned crystalline gypsum for secondary crushing and stirring, and pulverize it into granules.

Embodiment 3

[0019] Take 50kg of fluorogypsum and 50kg of titanium gypsum and mix them evenly; then add glauberite gypsum, the content of sodium sulfate in the glauberite gypsum accounts for 0.2% of the total gypsum mass, and carry out the reaction.

[0020] Take the above-mentioned crystalline gypsum for secondary crushing and stirring, and pulverize it into granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com