Multilayer aerobic fermentation system and fermentation method thereof

An aerobic fermentation and system technology, applied in liquid/slurry treatment, application, organic fertilizer and other directions, can solve the problems of high cost of conditioner dosage and large nitrogen loss, and achieve a single composition, reduce treatment costs, and improve fermentation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

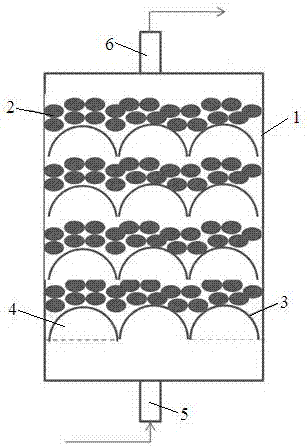

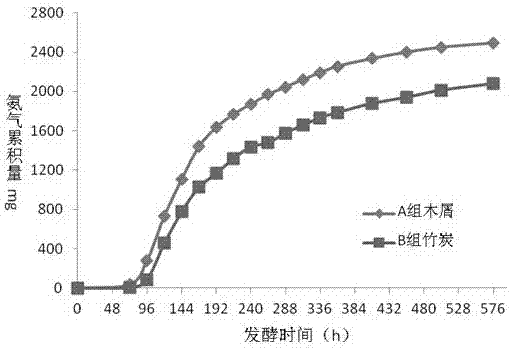

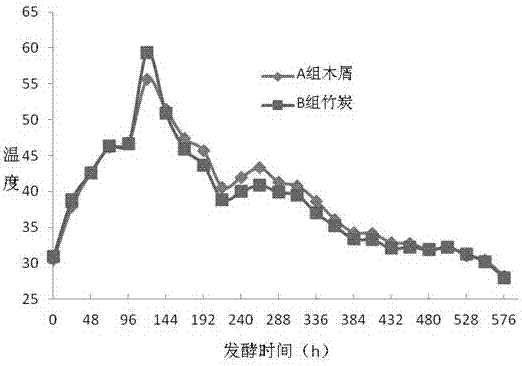

[0021] The commercially available cylindrical bamboo charcoal is broken into semi-cylindrical bamboo charcoal, and then dewatered sludge and bamboo charcoal layers are alternately layered on the inside of the fermentation tank to ensure that a layer of bamboo charcoal is arranged at the ventilation opening at the bottom of the fermentation tank. The layer is composed of a plurality of semi-cylindrical bamboo charcoal horizontal single layers with downward openings, and the thickness of each layer of dewatered sludge is 2-3cm, and then the laid bamboo charcoal layer and dewatered sludge are subjected to aerobic fermentation, and the ventilation rate is 1m 3 / min, the fermentation cycle is 28d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com