Nano magnesium hydroxide/hexagonal boron nitride nanocomposite material and preparation method

A nano-magnesium hydroxide and nano-composite material technology is applied in the field of material preparation, which can solve the problem of only 340 degrees of flame retardant temperature, and achieve the effect of improving the flame retardant temperature and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

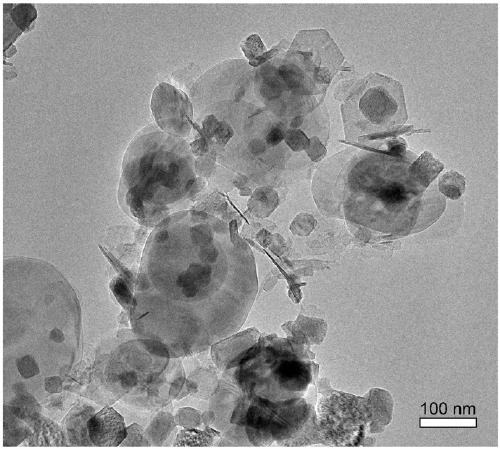

Image

Examples

Embodiment 1

[0021] Commercially available hexagonal boron nitride powder was added to dimethylformamide to obtain a 2.9% hexagonal boron nitride solution and sonicated for 8 hours. Pour the sonicated solution into a centrifuge tube and centrifuge at 5000 rpm for 5 minutes. Pour the supernatant into a beaker and dry it at 80 degrees Celsius to obtain a powder.

[0022] Dissolve 2 parts of magnesium chloride in 40 parts of deionized water to obtain a magnesium chloride solution. Weigh 0.5 parts of the above-mentioned hexagonal boron nitride powder and stir it into the calcium chloride solution and heat it to 180 degrees Celsius. Dissolve 10 parts of sodium hydroxide in 1 part of deionized water to obtain a sodium hydroxide solution. When the solution of magnesium chloride and powder is heated to 180 degrees centigrade, sodium hydroxide solution is added rapidly therein, and the insulation is continued for 24 hours after completion. After the incubation period, it was cooled to room tempe...

Embodiment 2

[0024] Add commercially available hexagonal boron nitride powder into dimethylformamide to obtain a 3.5% hexagonal boron nitride solution and sonicate for 10 h. Pour the sonicated solution into a centrifuge tube and centrifuge at 6000 rpm for 8 minutes. Pour the supernatant into a beaker and dry at 90°C to obtain a powder.

[0025] Dissolve 3 parts of magnesium chloride in 60 parts of deionized water to obtain a magnesium chloride solution. Weigh 0.7 parts of the above-mentioned hexagonal boron nitride powder, stir and add it into the calcium chloride solution and heat it to 200 degrees Celsius. Dissolve 20 parts of sodium hydroxide in 2 parts of deionized water to obtain a sodium hydroxide solution. After the solution of magnesium chloride and powder is heated to 200 degrees Celsius, add sodium hydroxide solution rapidly therein, and continue to keep warm for hours after finishing. After the incubation period, it was cooled to room temperature. The solution was then vacuu...

Embodiment 3

[0027] Add commercially available hexagonal boron nitride powder into dimethylformamide to obtain a 4.3% hexagonal boron nitride solution and sonicate for 12 hours. Pour the sonicated solution into a centrifuge tube and centrifuge at 7000 rpm for 10 minutes. Pour the supernatant into a beaker and dry it at 100 degrees Celsius to obtain a powder.

[0028] Dissolve 4 parts of magnesium chloride in 80 parts of deionized water to obtain a magnesium chloride solution. Weigh 1.5 parts of the above-mentioned hexagonal boron nitride powder and stir it into the calcium chloride solution and heat it to 220 degrees Celsius. Dissolve 20 parts of sodium hydroxide in 2 parts of deionized water to obtain a sodium hydroxide solution. After the solution of magnesium chloride and powder is heated to 220 degrees Celsius, sodium hydroxide solution is added rapidly therein, and the insulation is continued for 48 hours after completion. After the incubation period, it was cooled to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com