Dry type liquid-state wine brewing process of yellow wine

A rice wine, dry-type technology, applied in the field of dry-type liquid brewing technology of rice wine, can solve the problems of affecting the surrounding environment, high rice milk water, occupying space, etc., achieve a stable fermentation process, eliminate the production of rice milk water, and high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

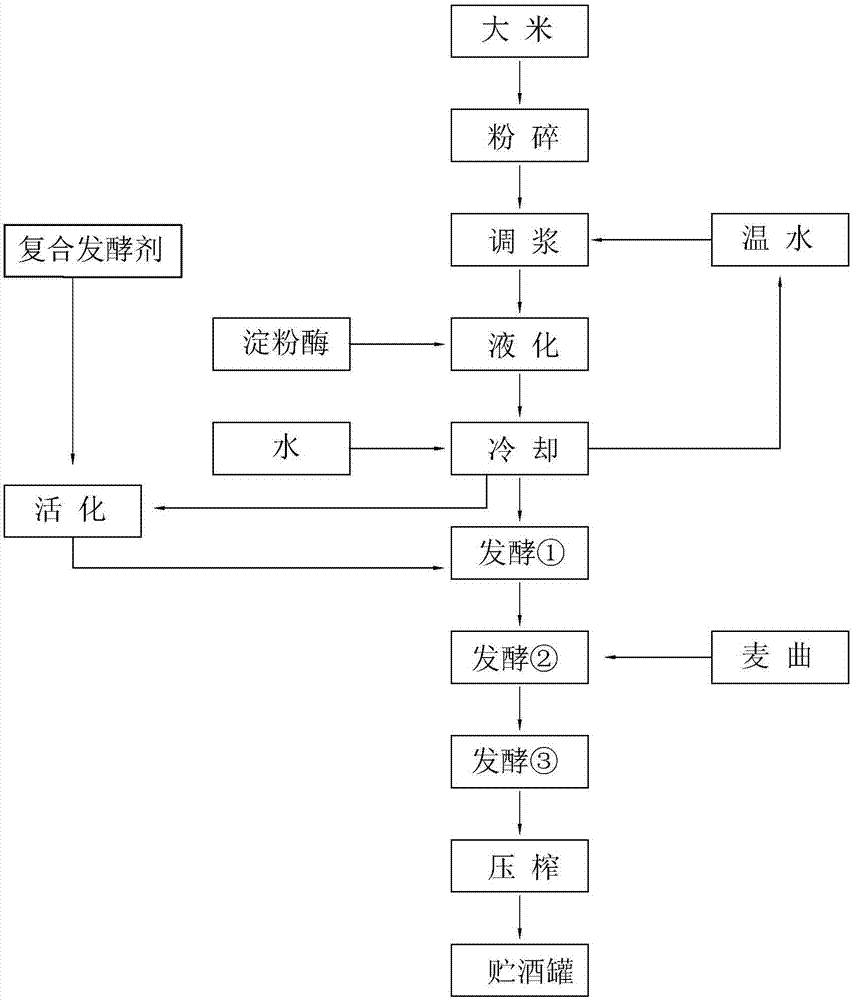

[0049] Embodiment 1: as figure 1 Shown, a kind of dry type liquid brewing process of yellow rice wine, comprises the following steps:

[0050] (1) Grinding: Grinding glutinous rice or japonica rice to obtain rice flour with a particle size of 40 mesh, and the moisture content of the rice flour is not more than 15%;

[0051] (2) Slurry mixing: Slowly put rice flour into water and stir to obtain a slurry. During the process of adding rice flour, the slurry remains in a flowing state while stirring, so that the rice flour is not easy to agglomerate. The weight ratio of rice to water in the slurry mixing process 1:1.5;

[0052] (3) Liquefaction: After slurry preparation is completed, heat the slurry to 55°C, add one or more of amylase, red yeast rice, niger yeast and rhizopus, and mid-temperature amylase, red yeast rice, niger yeast and rhizopus The total amount of one or more of them accounts for 85% of the weight of the rice flour, wherein the mesophilic amylase accounts for 1...

Embodiment 2

[0060] Embodiment 2: a kind of dry type liquid brewing process of yellow rice wine, comprises the following steps:

[0061] (1) Grinding: Grinding glutinous rice or japonica rice to obtain rice flour with a particle size of 60 mesh, and the moisture content of the rice flour is not more than 15%;

[0062] (2) Slurry mixing: Slowly put rice flour into water and stir to obtain a slurry. During the process of adding rice flour, the slurry remains in a flowing state while stirring, so that the rice flour is not easy to agglomerate. The weight ratio of rice to water in the slurry mixing process 1:2.5;

[0063] (3) Liquefaction: After slurry preparation is completed, heat the slurry to 55°C, add one or more of amylase, red yeast rice, niger yeast and rhizopus, and mid-temperature amylase, red yeast rice, niger yeast and rhizopus The total amount of one or more of them accounts for 30% of the weight of the rice flour, wherein the mesophilic amylase accounts for 4‰ of the weight of t...

Embodiment 3

[0071] Embodiment 3: a kind of dry type liquid brewing process of yellow rice wine, comprises the following steps:

[0072] (1) Grinding: Grinding glutinous rice or japonica rice to obtain rice flour with a particle size of 50 mesh, and the moisture content of the rice flour is not more than 15%;

[0073] (2) Slurry mixing: Slowly put rice flour into water and stir to obtain a slurry. During the process of adding rice flour, the slurry remains in a flowing state while stirring, so that the rice flour is not easy to agglomerate. The weight ratio of rice to water in the slurry mixing process 1:2;

[0074] (3) Liquefaction: After slurry preparation is completed, heat the slurry to 55°C, add one or more of amylase, red yeast rice, niger yeast and rhizopus, and mid-temperature amylase, red yeast rice, niger yeast and rhizopus The total amount of one or more of them accounts for 45% of the weight of the rice flour, wherein the mesophilic amylase accounts for 10‰ of the weight of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com