Lens coupling apparatus, structure and method based on flat window type TO package

A technology of a coupling device and a coupling structure, which is applied to the coupling of optical waveguides and other directions, can solve problems such as bad and the lens cannot be dynamically adjusted, and achieve the effect of improving the coupling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

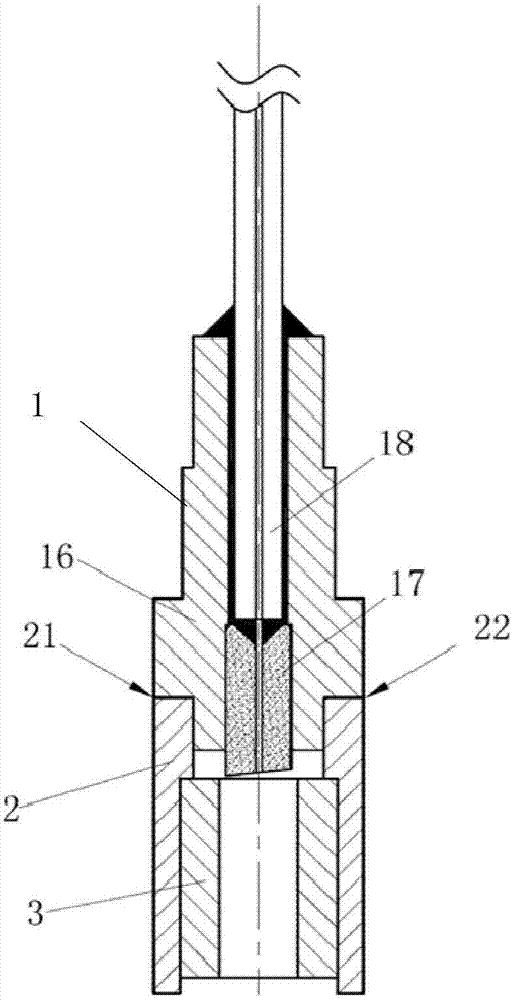

[0043] Embodiment 1 of the present invention provides a lens coupling device based on a flat-window TO package, such as figure 1As shown, the lens coupling device includes: a lens coupling pigtail 1, a coupling sleeve 2, and a magnetic ring 3, wherein the lens coupling device can be applied to the processing of flat-window TO-packaged lasers, and can also be applied to the Fabrication of photodetectors in flat-window TO packages. The lens coupling device is used as a grabbing part of a lens element 4 during specific use, and the lens coupling device can also be completed by using the test equipment connected to the pigtail 18 after grabbing the lens element 4 The lens couples the optical path to align for the final soldering process. Next, the connection structure between the constituent elements included in the lens coupling device will be described in detail.

[0044] Such as figure 1 As shown, the lens coupling pigtail 1 is composed of a metal jacket 16 and a ceramic fer...

Embodiment 2

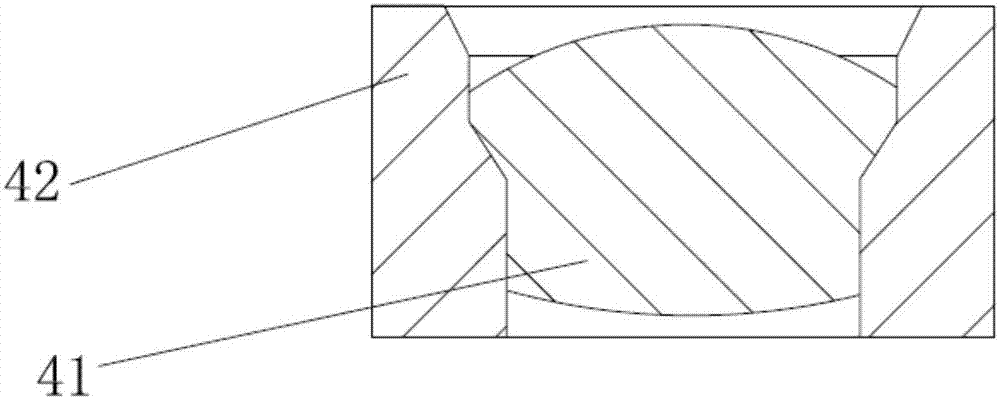

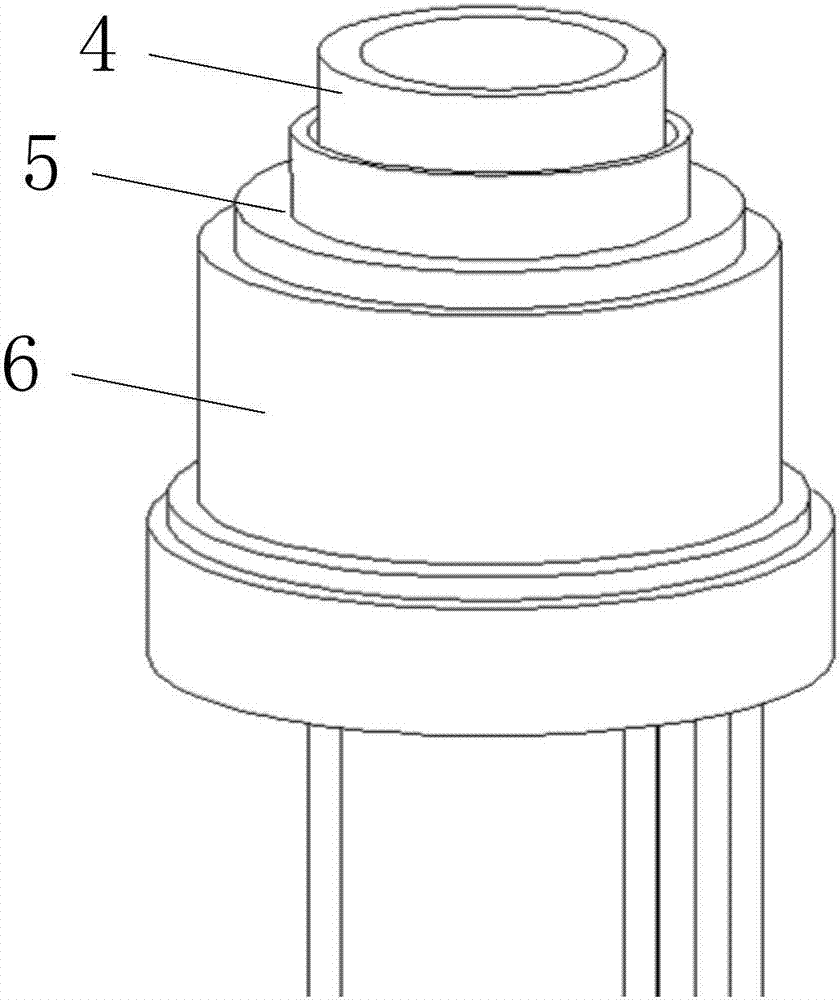

[0054] The existence value of the embodiment of the present invention is the lens coupling structure (that is, the flat window TO packaged optical device) that can be used as a supporting device for the lens coupling device described in Embodiment 1. Such as image 3 As shown, it is a lens coupling structure based on a flat-window TO package proposed by an embodiment of the present invention, including a lens element 4, a lens coupling adjustment ring 5, and a flat-window TO6. The lens element 4 includes an aspheric lens 41 and The peripheral metal 42, the aspherical lens is press-fitted inside the peripheral metal 42, and the material of the peripheral metal 42 is stainless steel with certain magnetic properties;

[0055] At least three laser welding spots are arranged between the lens coupling adjustment ring 5 and the outer diameter of the peripheral metal 42 of the lens element 4, wherein the peripheral metal 42 is set at the upper and lower positions of the lens coupling ...

Embodiment 3

[0063] In the embodiment of the present invention, in addition to providing the lens coupling device described in Embodiment 1 and the lens coupling structure described in Embodiment 2, a lens coupling method based on a flat-window TO package is provided, and the lens coupling Applied to the lens coupling device described in embodiment 1 and the lens coupling structure described in embodiment 2 in the method, such as Figure 4 and Figure 5 As shown, the coupling method specifically includes the following execution steps:

[0064] In step 201, the coupling device including the lens coupling pigtail 1, the coupling sleeve 2 and the magnetic ring 3 is installed on the coupling fixture.

[0065] Wherein, the coupling jig can be an existing jig, and the existing jig usually has fine-tuning functions in the X-axis, Y-axis and Z-axis directions, and when used in conjunction with the lens coupling device proposed in Embodiment 1 of the present invention, It only needs to fix the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com