Method and apparatus for optimizing reverse recovery characteristic of body diode

A technology of reverse recovery and body diode, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of false gate opening, high voltage change rate of reverse recovery characteristics, high power consumption of devices, etc., to achieve Reduce the reverse voltage conversion rate, optimize the reverse recovery characteristics, and improve the effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] 1. Substrate material preparation, using an n-type zone-fused monocrystalline silicon substrate 3 with a resistivity of 21 Ω·cm and a thickness of 725 μm, and its crystal orientation is ;

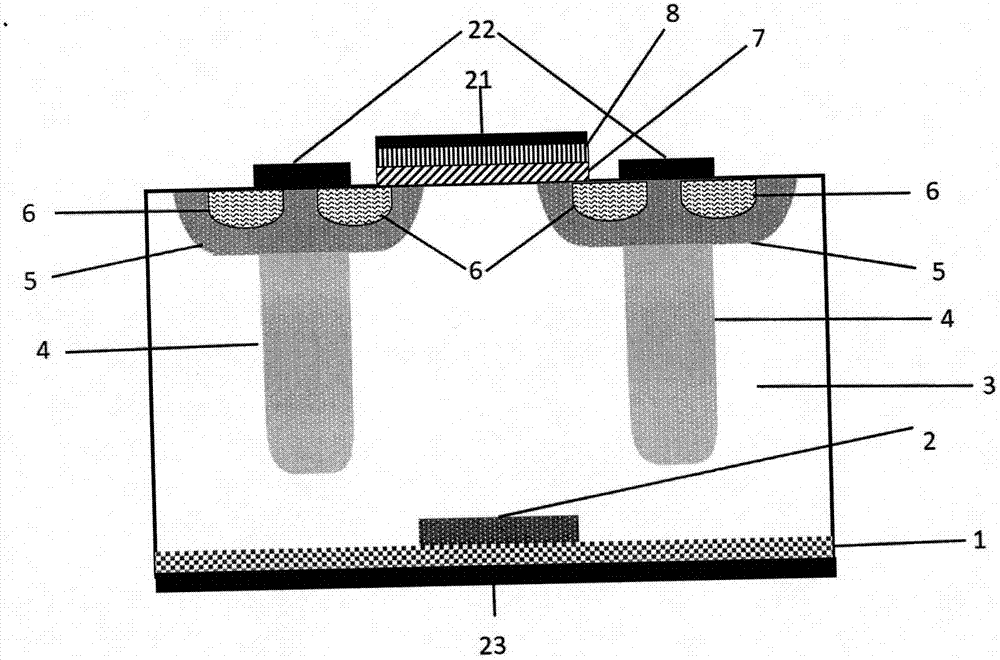

[0040] 2. Make a COOLMOS device structure on an n-doped substrate, including p-column 4, p+ doped region 5, n+ doped region 6, gate oxide layer 7, gate polysilicon 8, gate metal electrode 21, source metal electrodes 22;

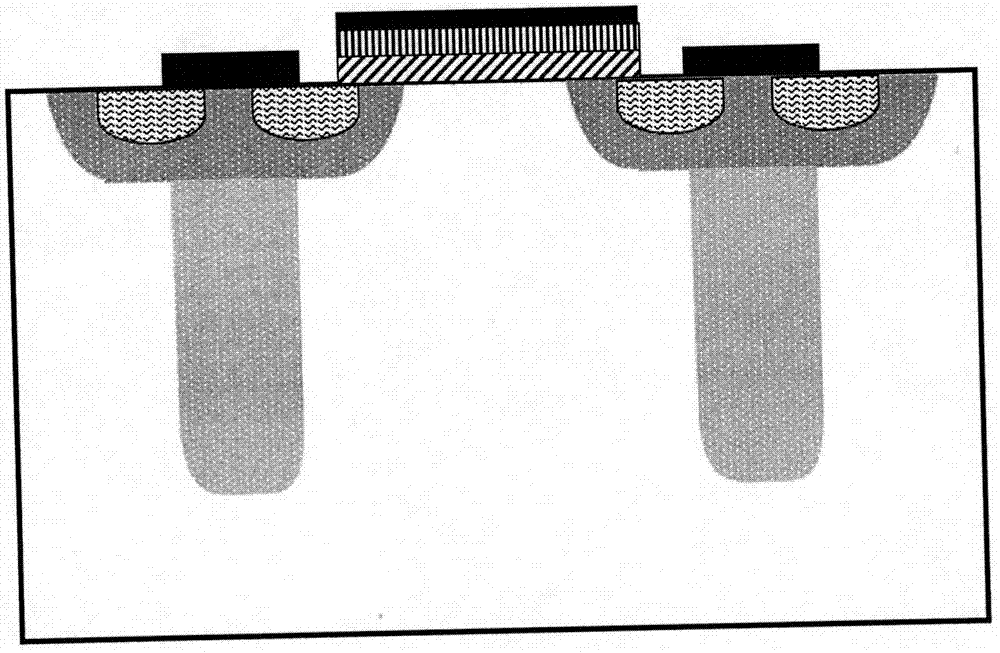

[0041] 3. Use a thinning machine to thin the wafer to 60 μm. like figure 2 shown.

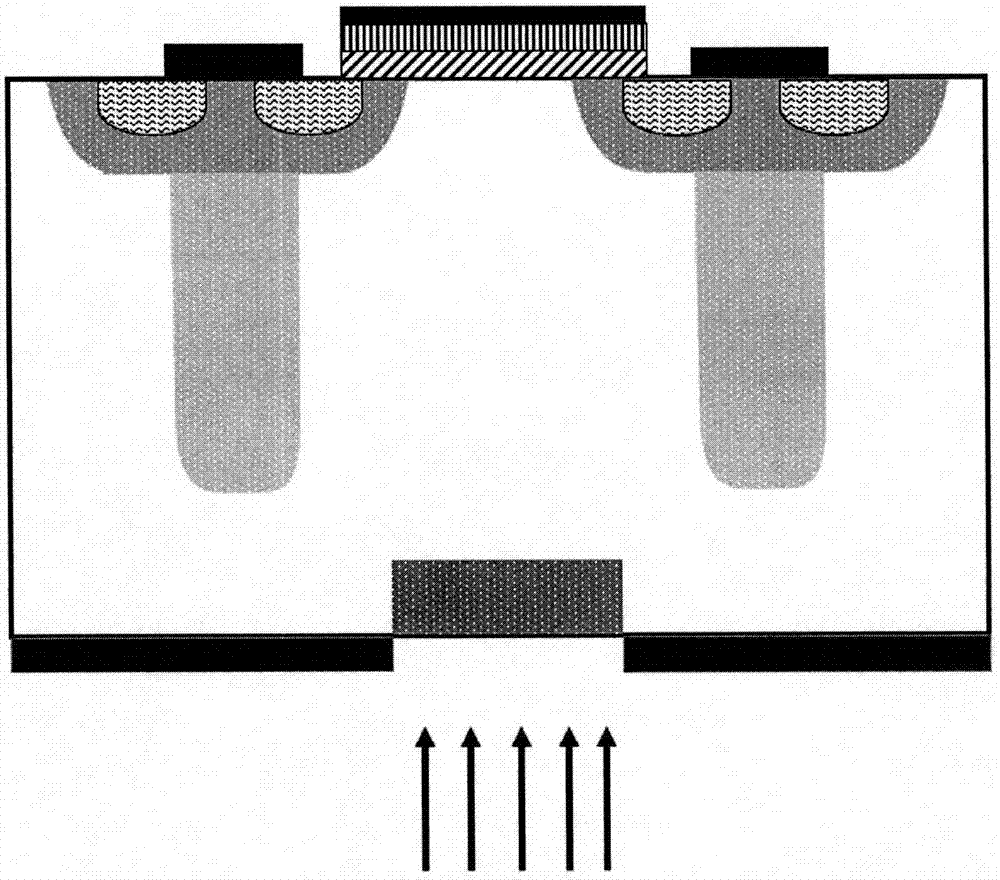

[0042] 4. Use n heavily doped photolithography mask to expose the back of the thinned n-doped substrate, and use photoresist to block local n-type ion implantation with an implantation dose of 1e 14 cm -2 , the implantation energy is 1000kev, and the implantation depth is about 1μm, such as image 3 shown.

[0043] 5. Remove the photoresist in step 4, and implant global n-type super-heavily doped ions on the back of the device, with an implantation dose of 3e 15 cm -2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com