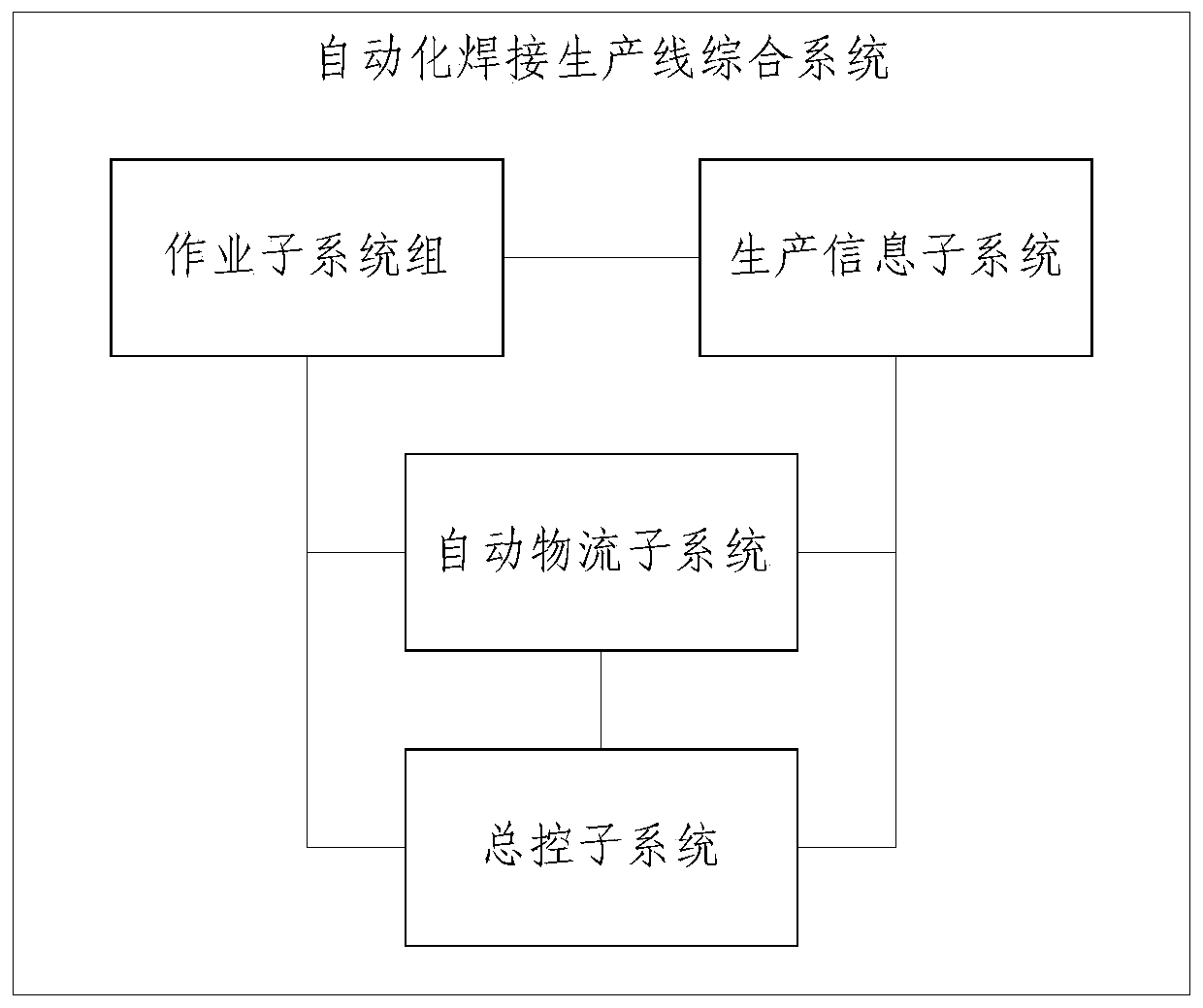

A comprehensive system of automatic welding production line

An automatic welding and comprehensive system technology, applied in the field of automatic welding production line comprehensive system, can solve the problems of high labor intensity, low output per unit area, difficult recruitment of grinding technology, etc., to solve the impact of production line capacity and improve the efficiency of welding operations , The effect of saving human resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

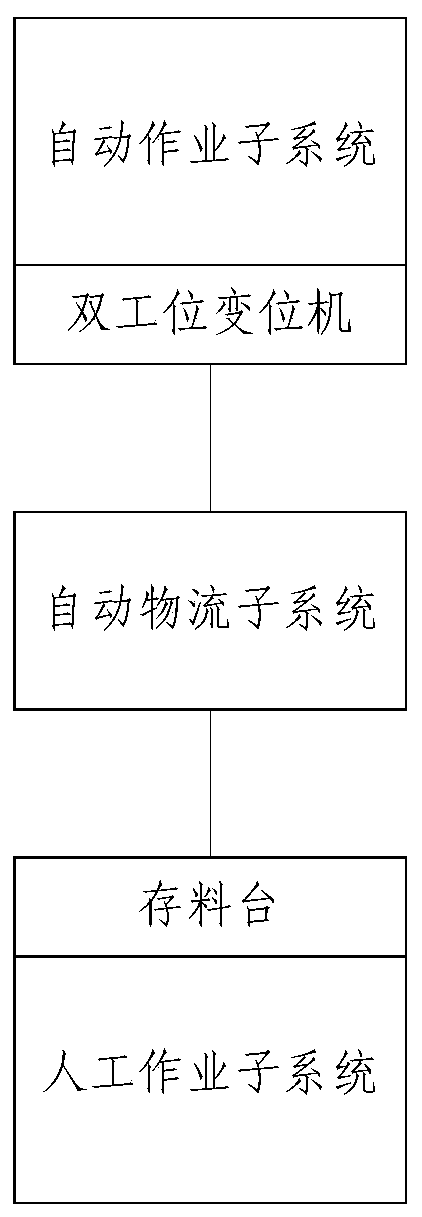

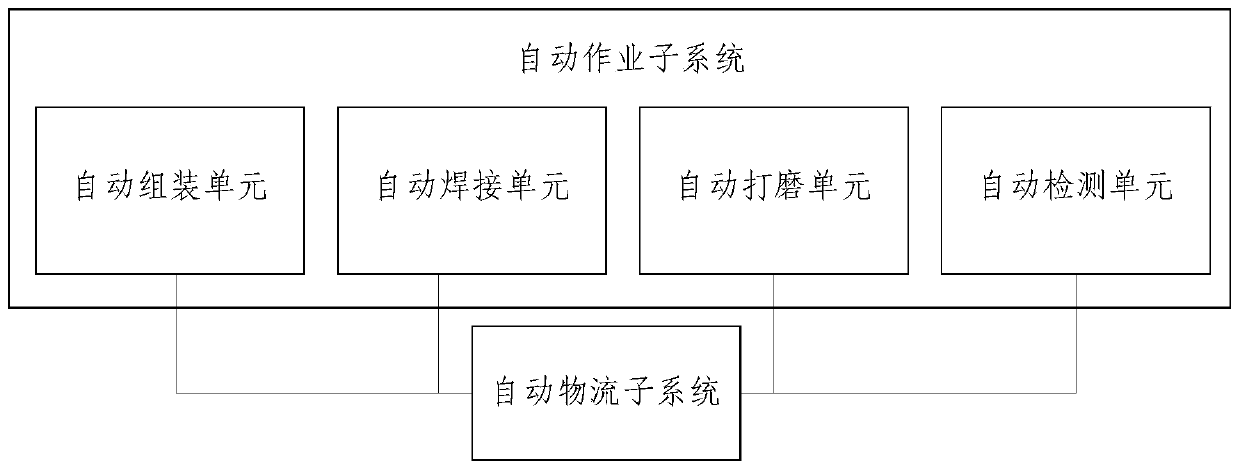

[0048] Embodiment 2 of the present invention provides another specific implementation manner of the above-mentioned comprehensive system, and the comprehensive system specifically includes the following contents:

[0049] The comprehensive system is set in the factory building, and the factory building is provided with a transportation channel connecting the subsystems in the comprehensive system; correspondingly, the automatic logistics subsystem is set at the center of the factory building, and The automatic logistics subsystem includes a plurality of transport vehicles, and the transport vehicles are used for transporting materials between various subsystems in the integrated system through the transport channel.

[0050] It can be understood that the automatic logistics subsystem is arranged in the middle of the factory building, and each subsystem is arranged on both sides of the automatic logistics subsystem according to the product process flow. The system (RGV) realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com