Production method for manufacturing potassium magnesium sulfate granules and application of potassium magnesium sulfate granules

A technology of potassium magnesium sulfate and production method, applied in the directions of mixing method, mold extrusion granulation, chemical instrument and method, etc., can solve the problems of increased manufacturing cost, reduced nutrient content, energy consumption, etc. Energy consumption, the effect of meeting the needs of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content of the invention, features and effects of the present invention, the following examples are exemplified and described in detail as follows:

[0028] The production method of making potassium magnesium sulfate particles, comprises the following production steps:

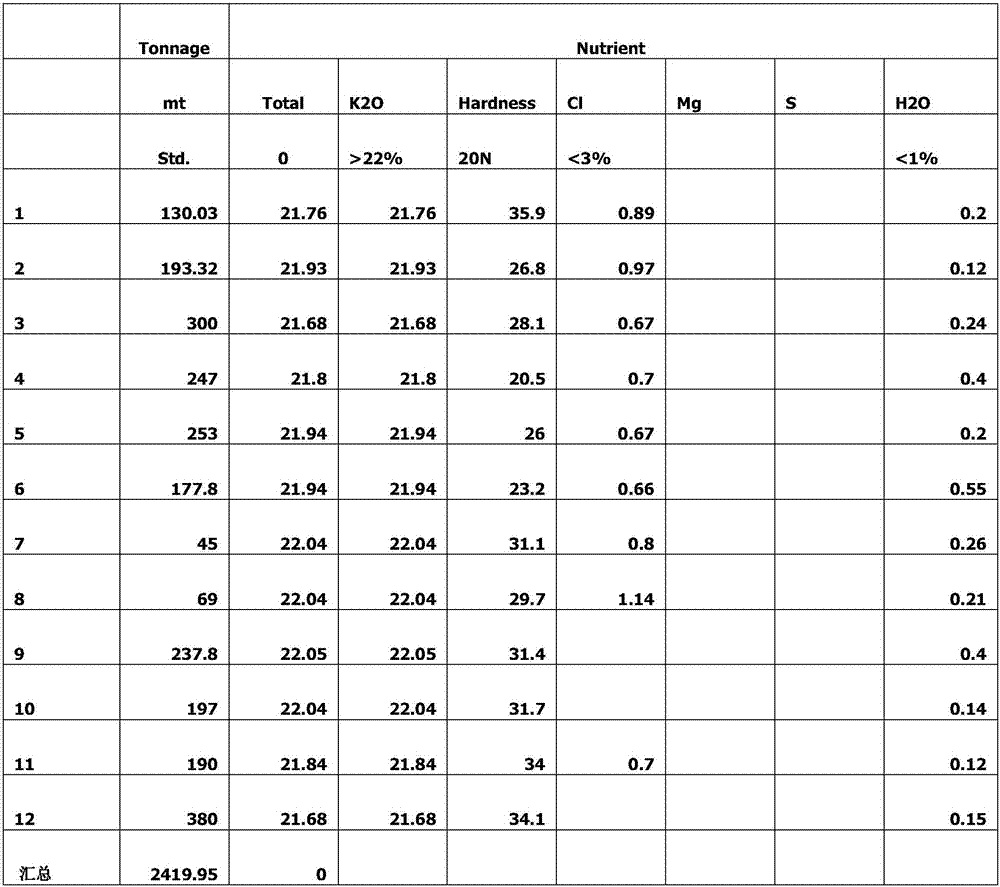

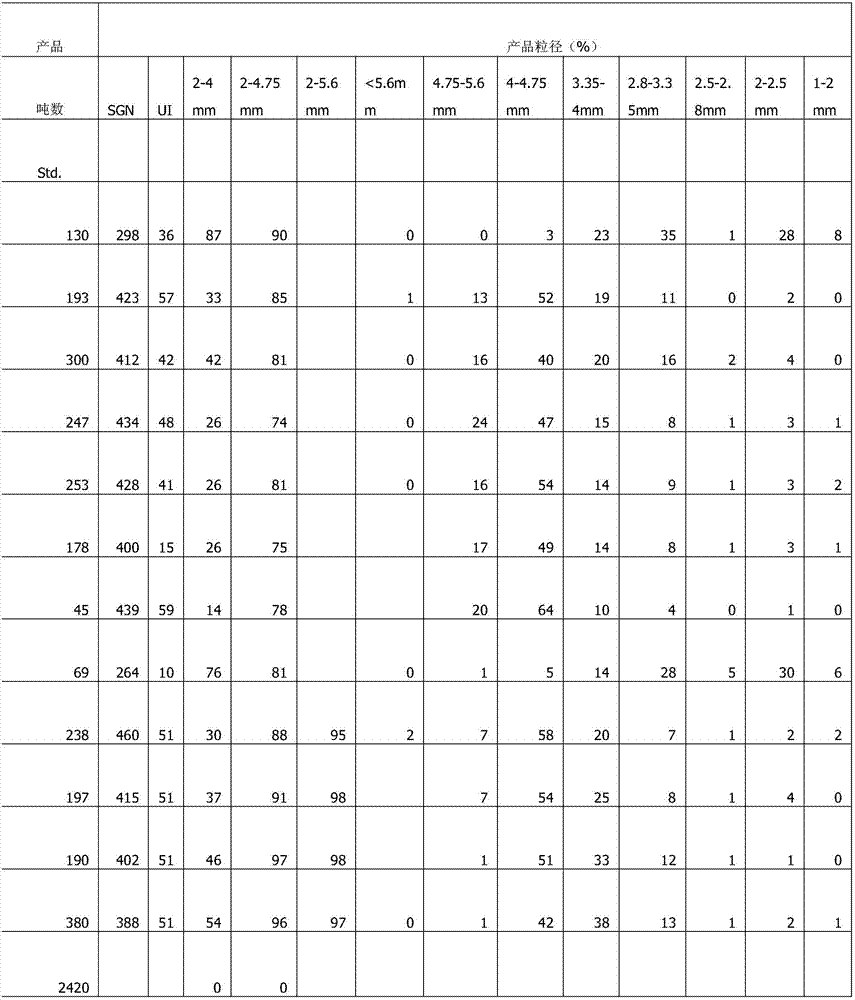

[0029] S1 feeding: the raw material potassium and magnesium sulfate is transported to the mixing and stirring equipment by belt conveyor or elevator after being metered. Among them, the raw material potassium and magnesium sulfate adopts standard grade imported potassium and magnesium sulfate.

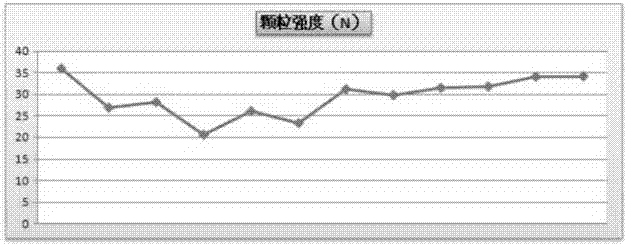

[0030] S2 batching and mixing: Add ammonium sulfate solution and water to the mixing and stirring equipment, and stir in the mixing and stirring equipment for a few minutes, usually about 3 minutes, observe the color change of the raw materials, and when the raw materials turn dark red, they can be formed into groups by hand. When the raw materials are in the same shape and do ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com