A method for device utilization of salt cavity

A technology of salt cavity and mine salt, applied in safety devices, mining devices, earthwork drilling and mining, etc., to achieve efficient resource utilization, eliminate geological disasters, and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

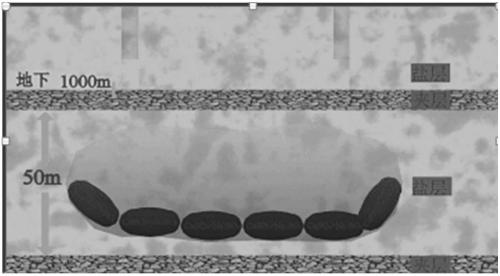

Embodiment 1

[0032] Select the salt cavern that is about to be exploited, and use sonar cavity measurement technology to measure the volume size and shape of the underground dissolution cavity of the vertical well. The volume of the dissolution cavity is about 50,000 m 3 . Desulfurization gypsum (solid waste produced by power plant flue gas desulfurization, the main component of which is CaSO 4 2H 2 O) Pulverized to have an average grain size of about 50 μm, mixed with ammonia-soda waste liquid (soda-making waste liquid, CaCl 2 105g / L); the NaCl content is about 50g / L), and then the mixture is injected into the above-mentioned salt cavity after brine extraction, reaching 50% of the total volume of the salt cavity, and the pH of the downhole fluid is adjusted to 8.5 with CaOH aqueous solution, so that the ammonia CaCl in alkaline waste liquid 2 Precipitation of calcium sulphate crystals from reaction with sodium sulphate in mines. After two months, the brine was pumped out, and it was ...

Embodiment 2

[0034] Select the salt cavern that is about to be exploited, and use sonar cavity measurement technology to measure the volume size and shape of the underground dissolution cavity of the vertical well. The volume of the dissolution cavity is about 100,000 m 3 . Desulfurization gypsum (solid waste produced by power plant flue gas desulfurization, the main component of which is CaSO 4 2H 2 O) After pulverizing to an average grain size of about 50 μm, mix with ammonia-soda waste liquid (soda-making waste liquid, CaCl 2 105g / L); NaCl content is about 50g / L), and then inject the mixture into the above-mentioned volume of about 100,000m 3 In the salt cavity after the brine mining, it reaches 50% of the total volume of the salt cavity, and the pH is adjusted to 8.5 with CaOH aqueous solution, so that the CaCl in the ammonia alkali waste liquid 2 Precipitation of calcium sulphate crystals from reaction with sodium sulphate in mines. After two months, the brine was pumped out, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com