Electrochromic vacuum glass

A vacuum glass, electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as ineffective regulation, and achieve the effects of sound insulation of ultraviolet radiation, good discoloration uniformity, and prevention of ultraviolet radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

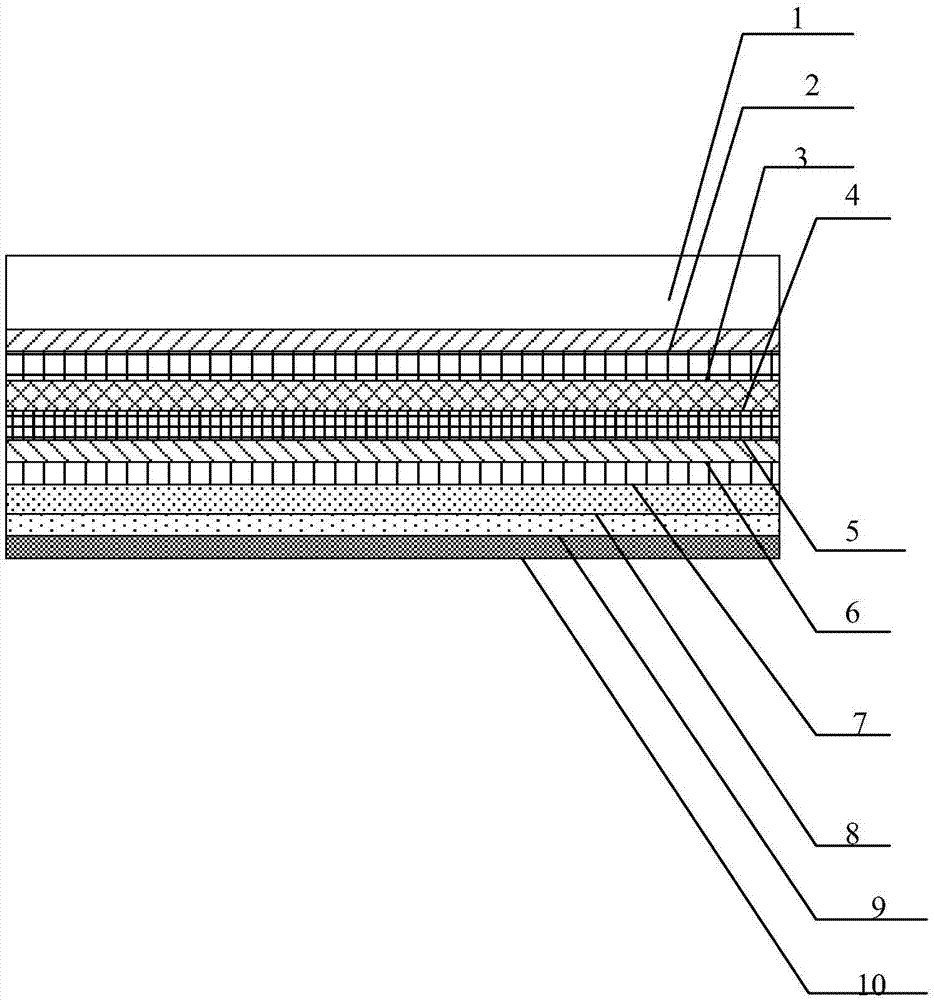

[0065] An electrochromic vacuum glass, comprising a substrate 1, a transparent oxide upper conductive layer 2, a cathode electrochromic layer 3, an ion conductive layer 4, an anode electrochromic layer 5, and a transparent oxide lower conductive layer stacked in sequence 6. Transparent adhesive layer 7 , inner glass 8 , vacuum layer 9 and outer glass 10 . The schematic diagram of the structure of the electrochromic vacuum glass of this embodiment is as follows figure 1 shown.

[0066] The specific material and thickness of each layer in the above layers are shown in Table 1.

[0067] Table 1 The parameter data table of the electrochromic vacuum glass of this embodiment

[0068]

[0069]

[0070] Detect the performance of the electrochromic vacuum glass of this embodiment, specifically: thermal insulation performance K=0.56W / (m 2 K); dew point test temperature -60°C pasting time 4 minutes, no frost, no condensation; sound transmission requires a medium, the sound insulat...

Embodiment 2

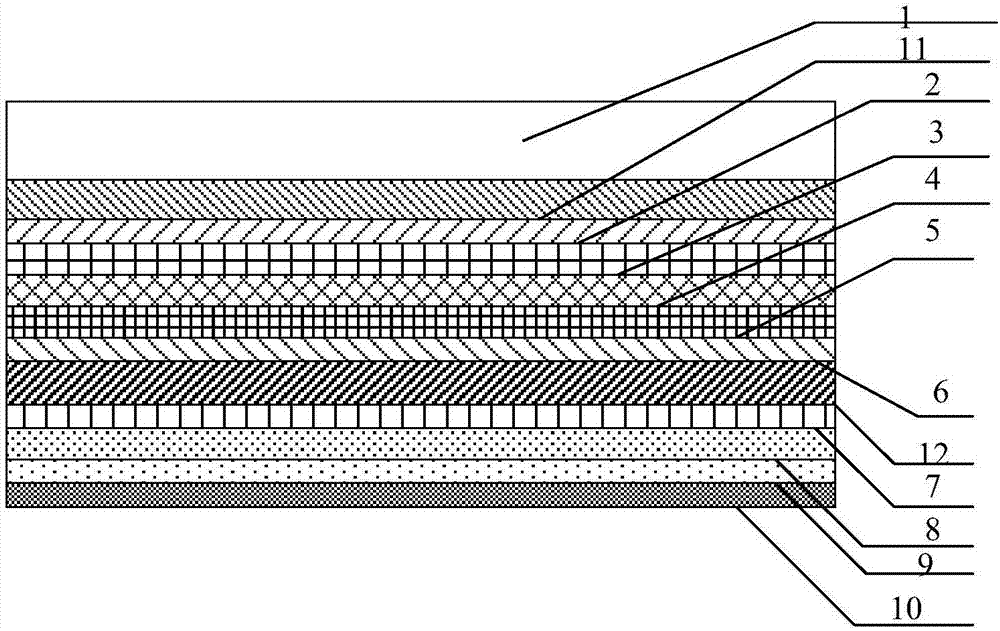

[0072] An electrochromic vacuum glass, comprising a substrate 1, an upper transparent oxidation insulating anti-penetration layer 11, a transparent oxide upper conductive layer 2, a cathode electrochromic layer 3, an ion conductive layer 4, and an anode electrochromic layer arranged sequentially. Layer 5, transparent oxide lower conductive layer 6, lower transparent oxide insulating anti-penetration layer 12, transparent adhesive layer 7, inner layer glass 8, vacuum layer 9 and outer layer glass 10. The schematic diagram of the structure of the electrochromic vacuum glass of this embodiment is as follows figure 2 shown.

Embodiment 3

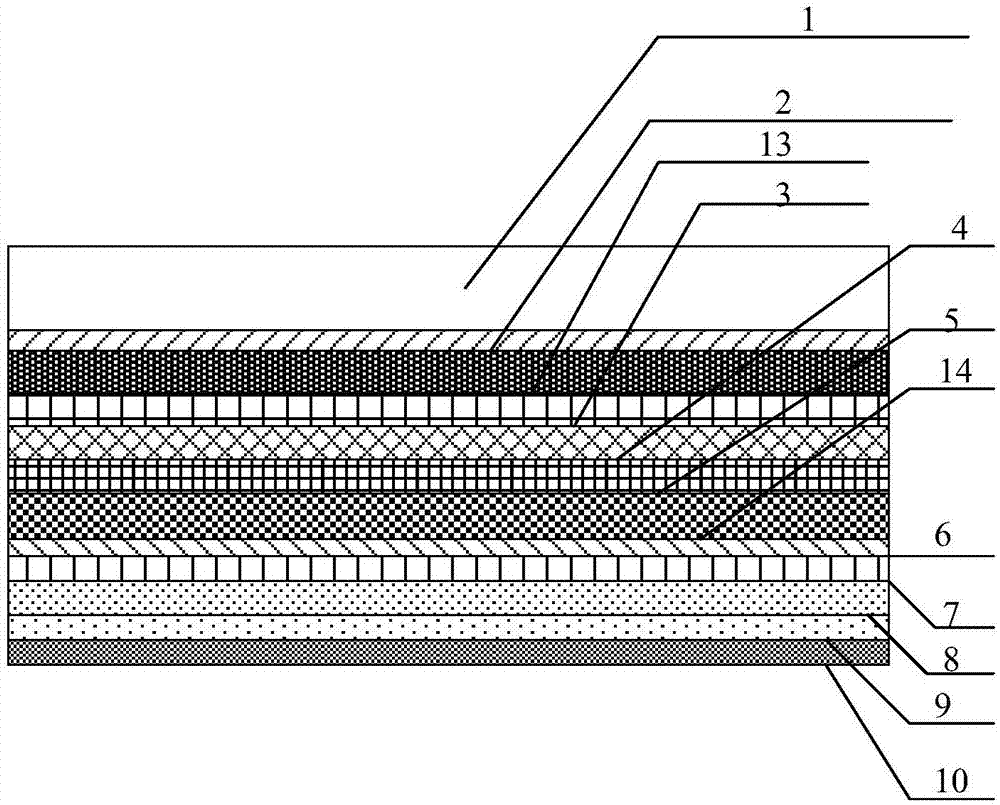

[0074] An electrochromic vacuum glass, comprising a substrate 1, a transparent oxide upper conductive layer 2, a metal mesh upper conductive layer 13, a cathode electrochromic layer 3, an ion conductive layer 4, and a positive electrochromic layer 5, which are sequentially stacked. , the conductive layer 14 under the metal mesh strip, the conductive layer 6 under the transparent oxide, the transparent adhesive layer 7 , the inner glass 8 , the vacuum layer 9 and the outer glass 10 . The schematic diagram of the structure of the electrochromic vacuum glass of this embodiment is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com