Preparation method of NiO/MgO/C composite negative electrode material of lithium ion battery

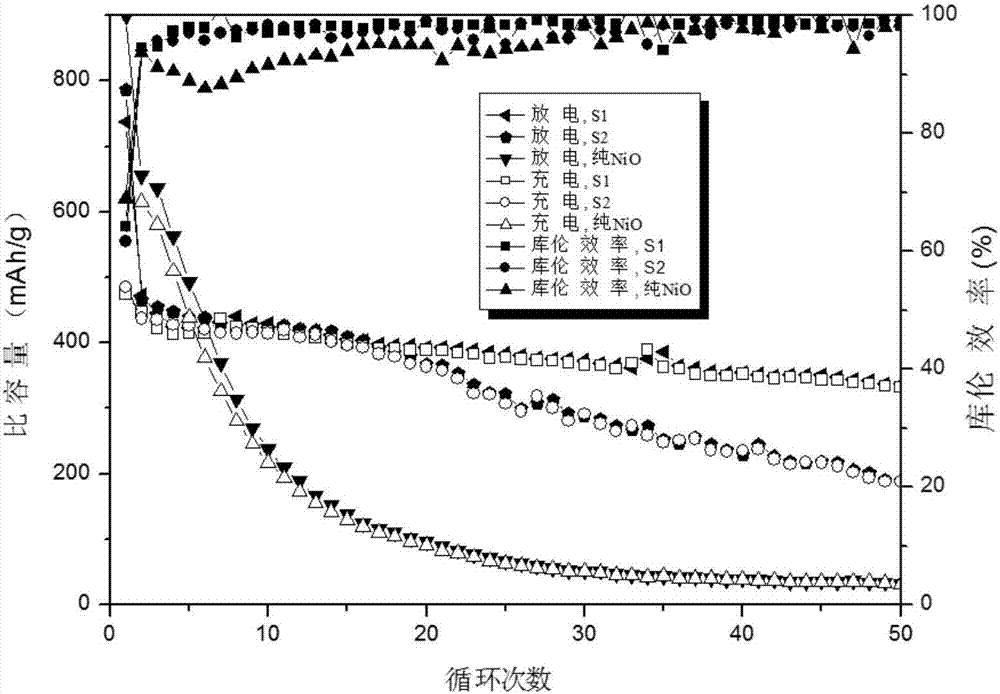

A technology of lithium-ion batteries and negative electrode materials, applied in the direction of battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve problems such as low specific capacity, improve electrical conductivity, improve long-term cycle performance and external The effect of stability and lithium storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

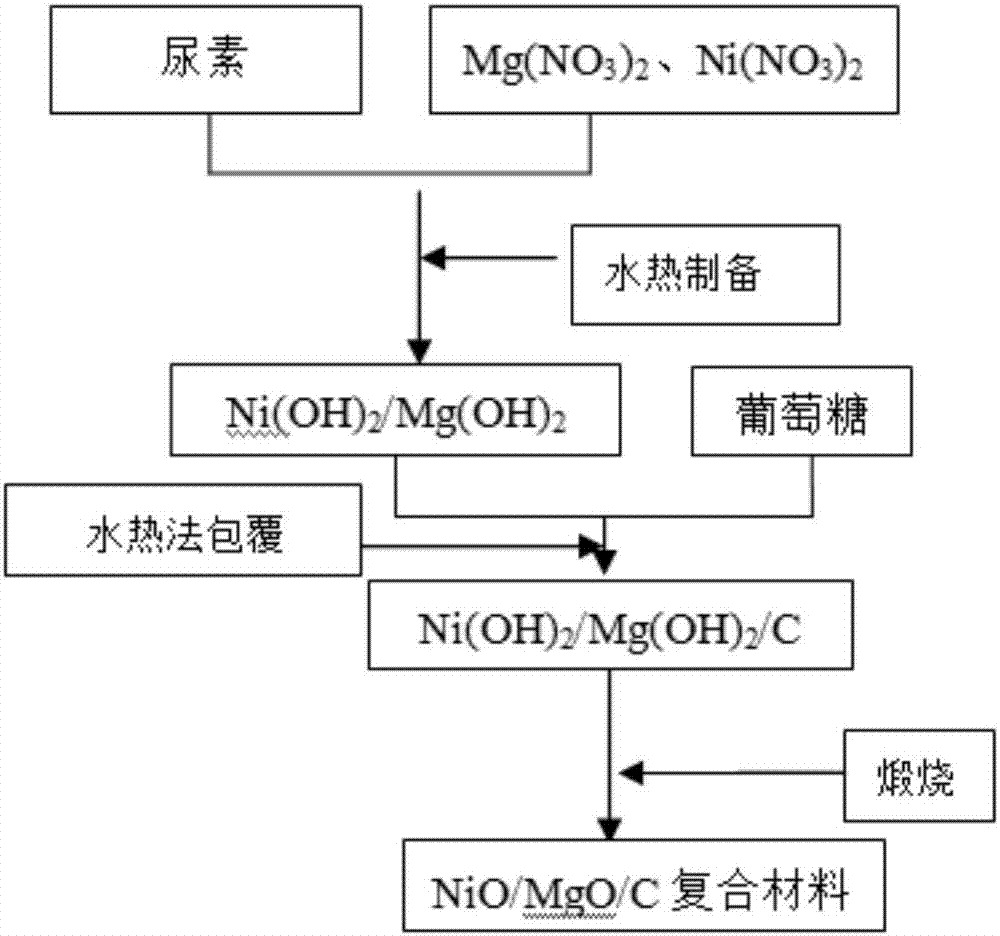

[0045] (1) Preparation of nano Ni(OH) 2 / Mg(OH) 2

[0046] 5.8gNi(NO 3 ) 2 ·6H 2 O and 2.38gMg(NO 3 ) 2 ·6H 2 O and 5.4 g of urea were dissolved in deionized water, the molar concentration of Ni was 0.1 mol / L, and stirred with a magnetic stirrer at room temperature until a homogeneous solution was obtained. Transfer this solution to a polytetrafluoroethylene reactor at 160°C for 6 hours, wash the obtained precipitate with deionized water and absolute ethanol, and then dry it at 60°C for 4 hours to obtain Ni(OH) 2 / Mg(OH) 2 .

[0047] (2) Preparation of NiO / MgO / C composite anode materials

[0048] Weigh 0.6g of Ni(OH) 2 / Mg(OH) 2 , added to 200ml of glucose aqueous solution with a concentration of 0.05mol / L to form a suspension, stirred at room temperature for 3 hours, transferred the suspension to a homogeneous reactor in a polytetrafluoroethylene reactor, and reacted at 180°C for 4 hours, The solid product was obtained and dried at 60°C for 24h, then calcined at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com