Dye adsorbent and preparation method thereof

A technology of adsorbents and dyes, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve problems such as secondary pollution of water bodies, and achieve the effects of strong adsorption capacity, convenient raw material acquisition, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

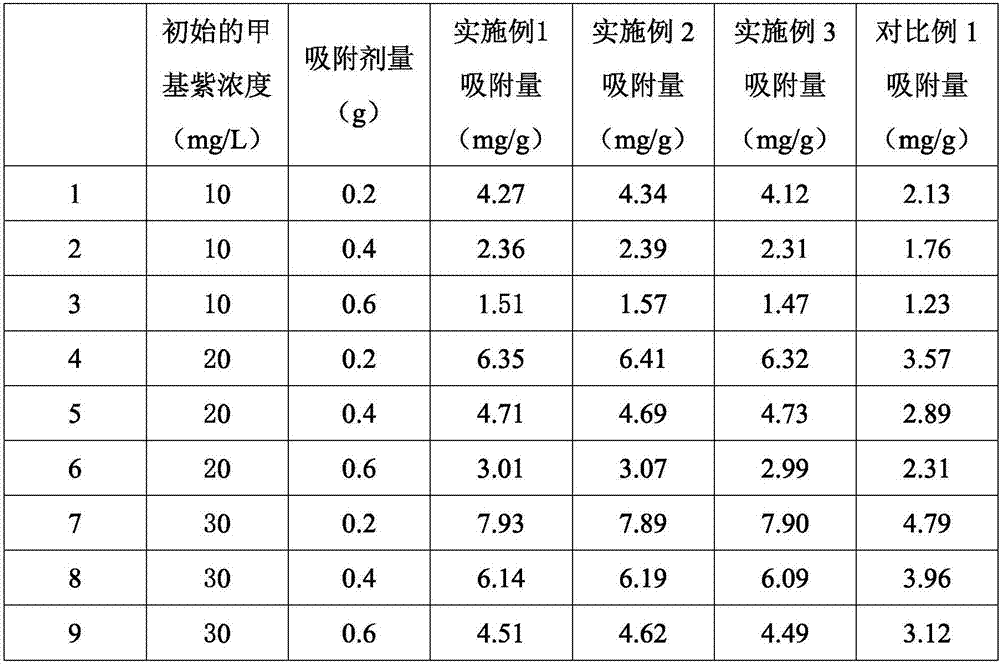

Examples

Embodiment 1

[0015] The pomelo peel powder dye adsorbent embedded in sodium alginate, its preparation method is:

[0016] (1) Pretreatment of discarded pomelo peel:

[0017] After the discarded pomelo peel was cut into pieces and soaked in a 3M NaOH solution for 30 minutes, the discarded grapefruit peel treated with the NaOH solution was obtained; then the discarded grapefruit peel treated with the NaOH solution was soaked in a 3M hydrochloric acid solution for 30 minutes; The discarded pomelo peels treated with NaOH solution and hydrochloric acid were washed several times with deionized water until the washing liquid reached neutrality. Then dry in an oven at 120° C. for 10 h, grind, and pass through a 100-mesh sieve to obtain pomelo peel powder.

[0018] (2) Embedding treatment of pomelo peel powder:

[0019] Weigh 10 g of pomelo peel powder treated in step 1) and mix with 20 mL of 2% sodium alginate solution, stir for 30 minutes until evenly mixed, then pour the mixture into 20 mL of ...

Embodiment 2

[0023] The pomelo peel powder dye adsorbent embedded in sodium alginate, its preparation method is:

[0024] (1) Pretreatment of discarded pomelo peel:

[0025] Cut the discarded pomelo peel into pieces and soak in 2M NaOH solution for 20 minutes to obtain discarded grapefruit peel treated with NaOH solution; then soak the discarded grapefruit peel treated with NaOH solution in 4M hydrochloric acid solution for 20 minutes; The discarded pomelo peels treated with NaOH solution and hydrochloric acid were washed several times with deionized water until the washing liquid reached neutrality. Then dry in an oven at 100° C. for 12 hours, grind, and pass through an 80-mesh sieve to obtain pomelo peel powder.

[0026] (2) Embedding treatment of pomelo peel powder:

[0027] Weigh 9.1g of pomelo peel powder treated in step 1) and mix with 21mL of 2% sodium alginate solution, stir for 20 minutes until uniformly mixed, then pour the mixture into 14mL of 0.1mol / L CaCl 2 solution, stirre...

Embodiment 3

[0031] The pomelo peel powder dye adsorbent embedded in sodium alginate, its preparation method is:

[0032] (1) Pretreatment of discarded pomelo peel:

[0033] Cut the discarded pomelo peel into pieces and soak in 2M hydrochloric acid solution for 20 minutes to obtain the discarded grapefruit peel treated with hydrochloric acid; then soak the discarded grapefruit peel treated with hydrochloric acid in 4M KOH solution for 20 minutes; The discarded pomelo peel treated with KOH solution was washed several times with deionized water until the washing solution reached neutrality. Then bake in an oven at 120°C for 12 hours, grind, and pass through a 100-mesh sieve to obtain pomelo peel powder.

[0034] (2) Embedding treatment of pomelo peel powder:

[0035] Weigh 10.5g of pomelo peel powder obtained by step 1) and mix it with 22.5mL of 2% sodium alginate solution, stir for 20 minutes until evenly mixed, then pour the mixture into 18mL of 0.1mol / L CaCl 2 solution, stirred for 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com