Compound cleaning method of rubber product mould

A technology for rubber products and molds, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high cost, inconvenient operation, and high cleaning cost, meet the requirements of reducing technical proficiency, and avoid poor cleaning effect. Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0054] S1. Regional analysis: Before cleaning, compare the accumulation of dirt before and after the use of the mold, and analyze the regional situation of the mold according to the comparison; the analysis of the regional situation finally divides the surface of the mold into heavily polluted areas and general polluted areas according to the dirt thickness threshold , the dirt thickness threshold is 1mm.

[0055] S2, spraying a mass fraction of 10% sodium bicarbonate or potassium bicarbonate solution on the surface of the mold until the surface of the mold is saturated, then evenly spraying 3% alum on the surface of the mold, and then standing for 3min;

[0056] S3, laser cleaning;

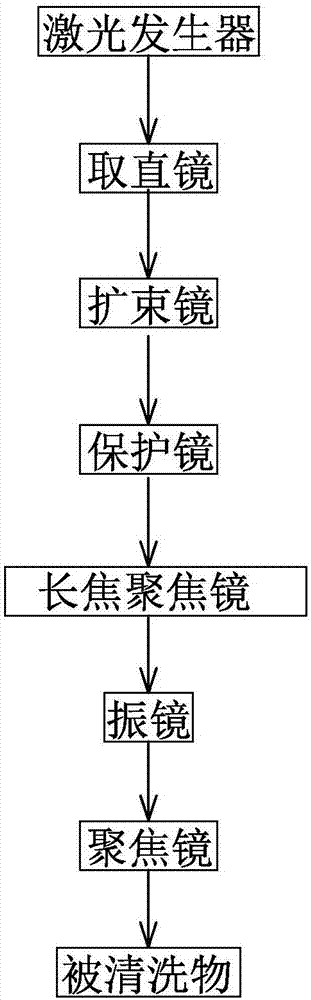

[0057] S31, turn on the laser generator to generate a laser beam;

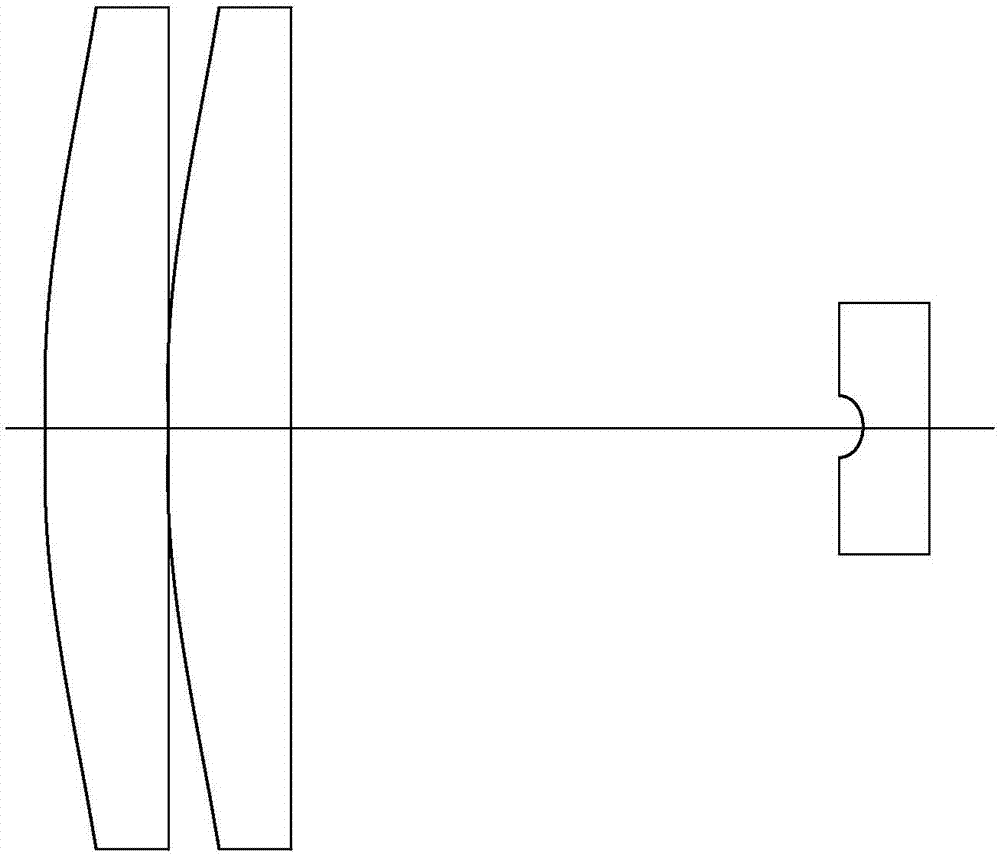

[0058] S32. The laser beam is irradiated on the straightening mirror, and the value mirror straightens the laser beam into a parallel beam;

[0059] S33, the beam after straightening is irradiated on the beam expander, and the ...

specific Embodiment 2

[0067] S1. Regional analysis: Before cleaning, compare the accumulation of dirt before and after the use of the mold, and analyze the regional situation of the mold according to the comparison; the analysis of the regional situation finally divides the surface of the mold into heavily polluted areas and general polluted areas according to the dirt thickness threshold , the dirt thickness threshold is 10mm.

[0068] S2, spraying a mass fraction of 20% sodium bicarbonate or potassium bicarbonate solution on the mold surface until the mold surface is saturated, then evenly spraying 25% alum to the mold surface, and then standing for 10min;

[0069] S3, laser cleaning;

[0070] S31, turn on the laser generator to generate a laser beam;

[0071] S32. The laser beam is irradiated on the straightening mirror, and the value mirror straightens the laser beam into a parallel beam;

[0072] S33, the beam after straightening is irradiated on the beam expander, and the beam expander expa...

specific Embodiment 3

[0080] S1. Regional analysis: Before cleaning, compare the accumulation of dirt before and after the use of the mold, and analyze the regional situation of the mold according to the comparison; the analysis of the regional situation finally divides the surface of the mold into heavily polluted areas and general polluted areas according to the dirt thickness threshold , the dirt thickness threshold is 6mm.

[0081] S2, spraying a mass fraction of 15% sodium bicarbonate or potassium bicarbonate solution on the mold surface until the mold surface is saturated, then evenly spraying 14% alum to the mold surface, and then standing for 7min;

[0082] S3, laser cleaning;

[0083] S31, turn on the laser generator to generate a laser beam;

[0084] S32. The laser beam is irradiated on the straightening mirror, and the value mirror straightens the laser beam into a parallel beam;

[0085] S33, the beam after straightening is irradiated on the beam expander, and the beam expander expand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com