Rust-cleaning shot blasting machine

A technology of shot blasting machine and shot blasting device, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems affecting the strength of steel, the size of projectiles is different, and the steel is over-corroded. High efficiency, good dust removal effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

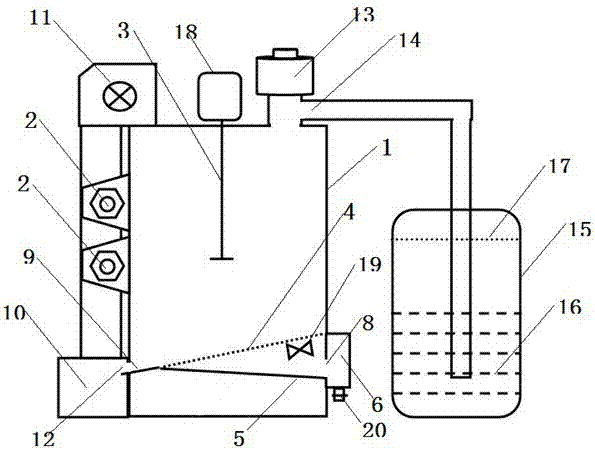

[0029] see figure 1 , a derusting shot blasting machine, comprising a chamber body 1, a derusting mechanism and a dedusting mechanism;

[0030] The derusting mechanism includes a derusting working part, a projectile sorting part and a projectile transmission part;

[0031] The derusting working part includes a shot blasting device 2 and a workpiece fixing device 3; the upper end of the workpiece fixing device 3 is fixed on the top of the chamber body 1, and the lower end is suspended inside the chamber body 1; the shot blasting device 2 is distributed in the chamber body 1 The side wall, the blasting direction is the lower end of the workpiece fixing device 3;

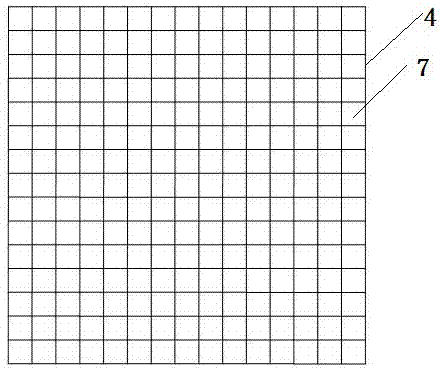

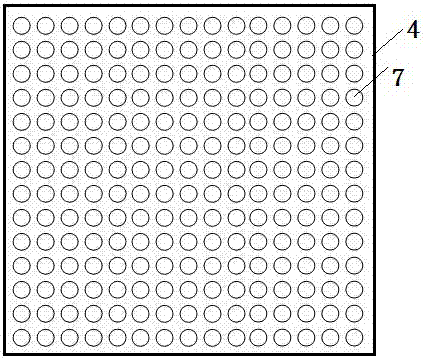

[0032] The projectile sorting part includes a projectile sieve plate 4, a waste material collection plate 5 and a waste material collection chamber 6; the projectile sieve plate 4 is provided with a gap 7, and the size of the gap 7 is smaller than the size of the projectile; one end of the projectile sieve plate 4 It...

Embodiment 2

[0038]In order to achieve a better separation and removal effect, multiple groups of projectile sorting parts can be set up. The adjacent two groups of projectile sorting parts are set opposite to each other. The vertical direction is staggered by one end distance. After the projectiles are separated from the projectile sorting part located on the top , falling into the adjacent projectile sieve plate 4 of the projectile sorting part below it, and continue to separate and remove impurities. The more the number of projectile sorting parts is, the longer the total distance of the projectile rolling is, and the better the effect of separation and removal of impurities is. , but the number of projectile sorting units is too large. On the one hand, it will cause the equipment to be too large, and it will also affect the work efficiency. Considering various factors, the number of projectile sorting units is preferably 1-6 groups, and 2-4 groups are the best. Figure 4 It is a schemat...

Embodiment 3

[0041] The upper end of the workpiece fixing device 3 described in Embodiment 1 is connected with the rotating motor 18. During derusting, the rotating motor drives the workpiece to rotate, so that the derusting efficiency is higher and the effect is better.

[0042] The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com