Method for preventing scabbing in ammonium metavanadate crystallization process

An ammonium metavanadate and crystallization technology, applied in the field of vanadium chemical metallurgy, can solve problems such as a large amount of capital and increase production costs, and achieve the effects of improving service life, improving production efficiency, and avoiding scarring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

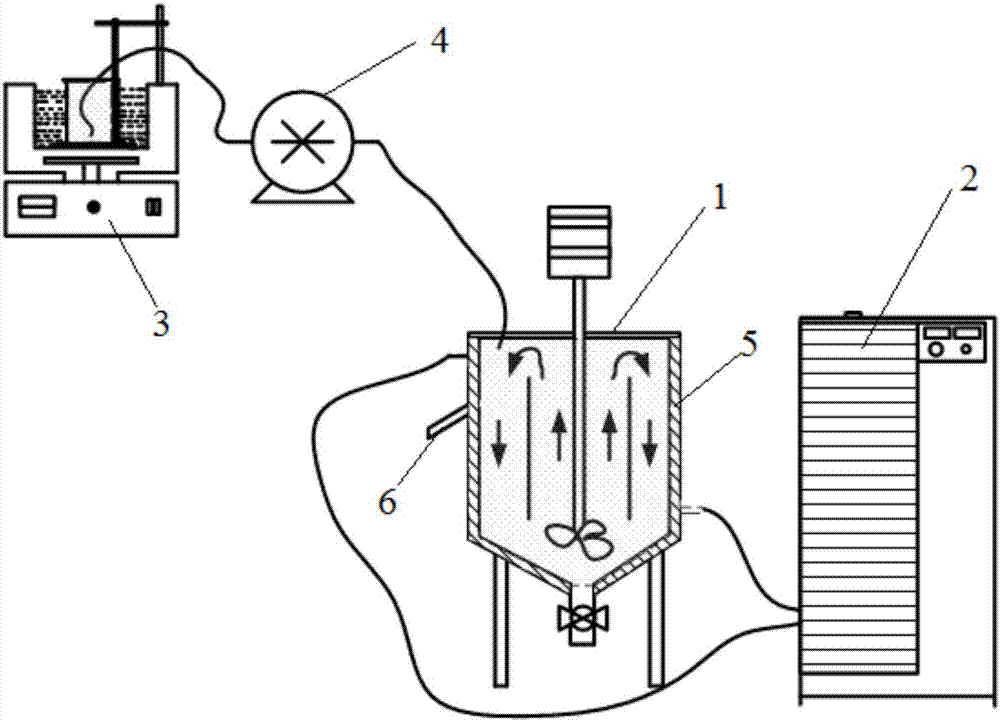

Image

Examples

Embodiment 1

[0039] (1) Prepare ammonium metavanadate mother liquor, the concentration of vanadium is 5g / L, carry out natural cooling crystallization, the obtained solid phase is used as crystal seed, and liquid phase is used as circulation liquid. The circulating liquid is added to the crystallizer, and the stirring is started at a speed of 100 r / min. Then, a seed crystal is added to the crystallizer, and the amount of the seed crystal added is 1% of the mass of the ammonium metavanadate mother liquor. Turn on the low temperature and constant temperature reaction bath, control the temperature, and ensure that the temperature of the circulating liquid in the crystallizer is always maintained at a constant temperature of 25°C.

[0040] (2) Prepare the ammonium metavanadate mother liquor of the same concentration as step (1), and keep it warm in a 90°C constant temperature water bath equipment, and use a flow pump to squeeze the mother liquor at 90°C into the crystallizer at a certain flow ra...

Embodiment 2

[0044] (1) Prepare ammonium metavanadate mother liquor, the concentration of vanadium is 15g / L, carry out natural cooling crystallization, the obtained solid phase is used as crystal seed, and liquid phase is used as circulating liquid. The circulating liquid is added to the crystallizer, and the stirring is started at a speed of 200 r / min, and then seed crystals are added to the crystallizer, and the seed crystal addition amount is 5% of the mass of the ammonium metavanadate mother liquor. Turn on the low temperature and constant temperature reaction bath, control the temperature, and ensure that the temperature of the circulating liquid in the crystallizer is always maintained at a constant temperature of 30°C.

[0045] (2) prepare the ammonium metavanadate mother liquor of identical concentration with step (1), and insulate in 80 ℃ of constant temperature water bath equipments, the mother liquor of 80 ℃ is squeezed into the crystallizer with certain flow rate with the flow p...

Embodiment 3

[0049] (1) Prepare ammonium metavanadate mother liquor, the concentration of vanadium is 30g / L, carry out natural cooling and crystallization, the obtained solid phase is used as crystal seed, and the liquid phase is used as circulating liquid. The circulating liquid is added to the crystallizer, and the stirring is started at a speed of 500 r / min. Then, seed crystals are added into the crystallizer, and the seed crystal addition amount is 20% of the mass of the ammonium metavanadate mother liquor. Turn on the low temperature and constant temperature reaction bath, control the temperature, and ensure that the temperature of the circulating liquid in the crystallizer is always maintained at a constant temperature of 35°C.

[0050] (2) Prepare the ammonium metavanadate mother liquor of the same concentration as step (1), and keep it warm in a 90°C constant temperature water bath equipment, and use a flow pump to squeeze the mother liquor at 90°C into the crystallizer at a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com