Defoaming agent for landfill leachate and preparation method thereof

A technology of landfill leachate and defoaming agent, applied in the field of defoaming agent and defoaming agent for landfill leachate, can solve the problems of difficult leachate treatment, environmental harm, toxic aquatic organic system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

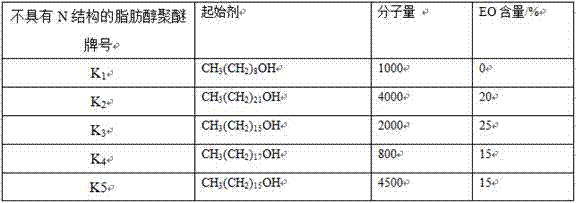

Method used

Image

Examples

Embodiment 1

[0039] 1. Add 100g glycerol polyether M 1 , 800g fatty alcohol polyether N 1 Add it into the stirring tank, start the stirring, the stirring time is 10min, make it mix evenly, and obtain the mixture Ⅰ-1;

[0040] 2. Add 100g of organic defoaming synergist E1 to the mixture Ⅰ-1, and continue to stir for 30 minutes to make it evenly mixed to obtain the mixture Ⅱ-1;

[0041] 3. After the stirring is finished, let the mixture II stand for 2 hours to obtain the defoamer X of the present invention 1 .

Embodiment 2

[0043] 1. Mix 500g glycerol polyether M 2 , 400g fatty alcohol polyether N 2 Add it into the stirring tank, start the stirring, the stirring time is 20min, make it mix evenly, and obtain the mixture Ⅰ-2;

[0044] 2. Add 100g of organic antifoam synergist E2 to the mixture Ⅰ-2, and continue to stir for 40 minutes to make it uniformly mixed to obtain the mixture Ⅱ-2;

[0045] 3. After the stirring is finished, let the mixture II stand for 3 hours to obtain the defoamer X of the present invention 2 .

Embodiment 3

[0047] 1. Add 300g glycerol polyether M 3 , 650g fatty alcohol polyether N 3 Add it into the stirring tank, start stirring, and stir for 30 minutes to make it evenly mixed to obtain the mixture Ⅰ-3;

[0048] 2. Add 50g of organic defoaming synergist E3 to the mixture Ⅰ-3, and continue to stir for 50 minutes to make it uniformly mixed to obtain the mixture Ⅱ-3;

[0049] 3. After the stirring is finished, let the mixture II stand for 4 hours to obtain the defoamer X of the present invention 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com