Method for extracting rosmarinic acid from labiates and prepared drug

A plant extract and rosmarinic acid technology, applied in the field of medicine, can solve the problems of high cost, difficulty in obtaining rosmarinic acid, complex process, etc., and achieve the effect of increased utilization, low price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

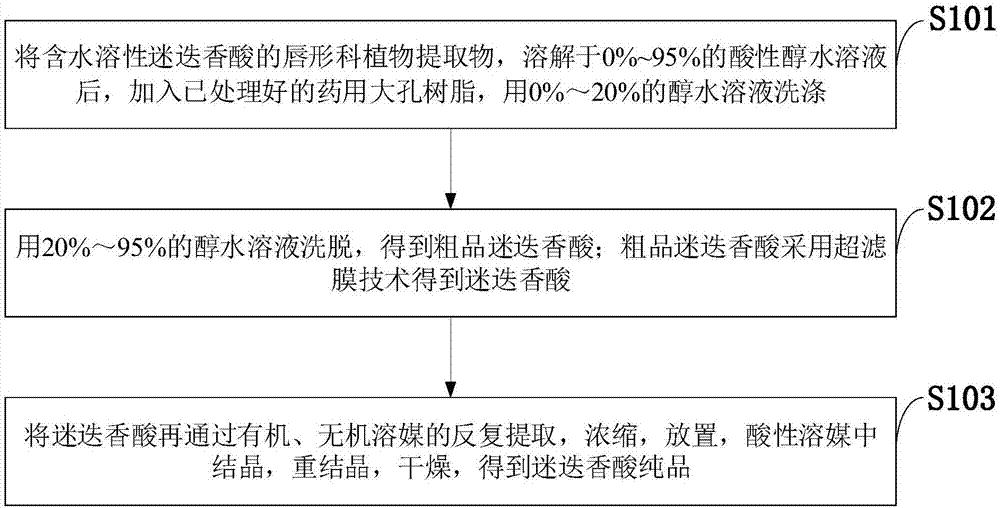

Method used

Image

Examples

Embodiment 1

[0044] Rosemary stems and leaves are crushed into coarse powder, distilled in 10-20 times of water at 40-100 degrees Celsius for 1-2 hours, and the distillate is placed separately to provide volatile oil; the distilled solution is filtered, and directly put on the prepared macroporous resin, That is, on the basis that the content of benzene is less than 1ppm, other solvents such as toluene and xylene should be less than 20ppm, and the total amount of residual organic solvents is less than 100ppm, wash it with 0-20% ethanol water, and then rinse it with 40-60% ethanol until it is free. Residue of marinic acid; reclaim ethanol, use the ultrafiltration membrane technology of molecular weight 400 to obtain the semi-finished product of rosmarinic acid, the above-mentioned semi-finished product is heated to 50 degrees Celsius in pure water with a pH of 3 to 4, dissolve the semi-finished product of rosmarinic acid as much as possible to the net, in Cool in a freezing chamber, crystall...

Embodiment 2

[0046] Rosemary stems and leaves are crushed into coarse powder, distilled in 10-20 times of water at 50-90 degrees Celsius for 1-2 hours, and the distillate is placed separately to provide volatile oil; the distilled solution is filtered and directly put on the prepared medicinal macropore Resin WLD, washed with 0, 20% ethanol in sequence, and then rinsed with 40-60% ethanol until no rosmarinic acid remains; recovering ethanol, using ultrafiltration membrane technology with a molecular weight of 400 to obtain semi-finished products of rosmarinic acid. Heat the pure water with pH 3-4 to 50 degrees Celsius, dissolve the semi-finished product of rosmarinic acid as much as possible to the net, cool it in the freezing room, crystallize, and repeat this process 3 times to obtain pure rosmarinic acid and pure rosmarinic acid. The content is 98%.

Embodiment 3

[0048] Rosemary stems and leaves are crushed into coarse powder, distilled in 14-20 times of water at 90 degrees Celsius for 1-2 hours, and the distillate is placed separately to provide volatile oil; the distilled solution is filtered and directly put on the prepared medicinal macroporous resin SP825 , washed with 0, 20% ethanol water successively, and then rinsed with 60% ethanol until no rosmarinic acid remains; reclaim the ethanol, and use the ultrafiltration membrane technology with a molecular weight of 400 to obtain the semi-finished product of rosmarinic acid until it is clean, and the above-mentioned semi-finished product is at pH3 Heat to 50 degrees centigrade in ~4 pure water, dissolve the semi-finished product of rosmarinic acid as far as possible to the net, cool in the freezing chamber, crystallize, and go back and forth 3 times like this, obtain the pure product of rosmarinic acid, the content of the pure product of rosmarinic acid is 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com