Down suction type radiation tube biomass pyrolysis carbonizing furnace

A technology of biomass pyrolysis and regenerative radiant tubes, which is applied in the field of downdraft radiant tube biomass pyrolysis charcoal furnaces, can solve problems such as production capacity decline, threats to transportation production, life safety, and damage to soil structure. To achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is further described:

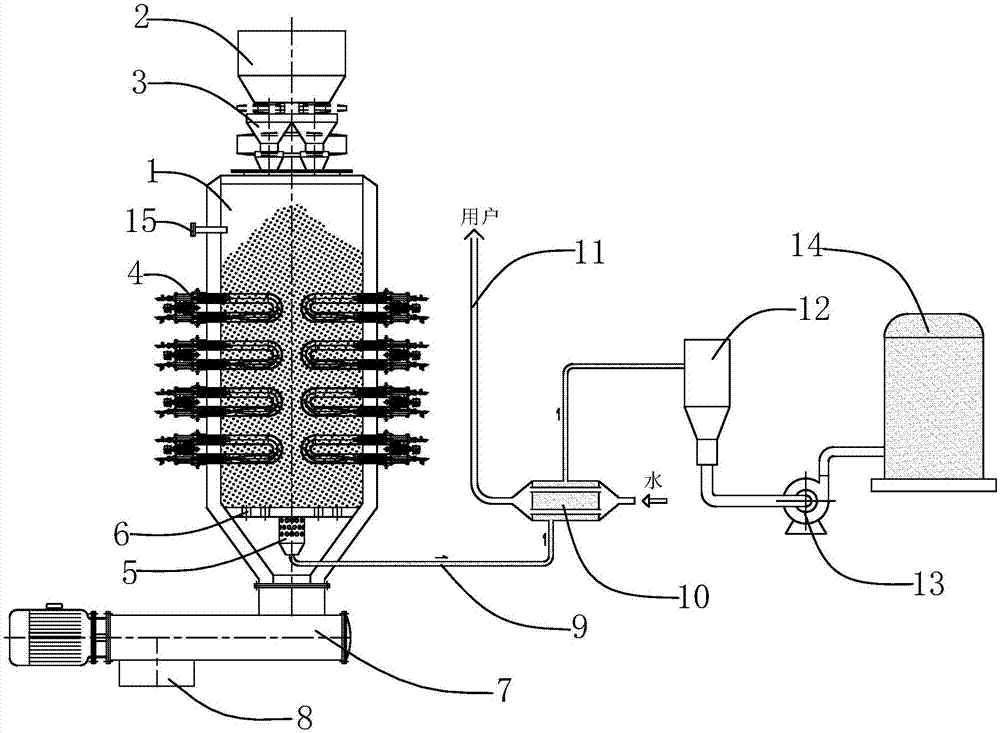

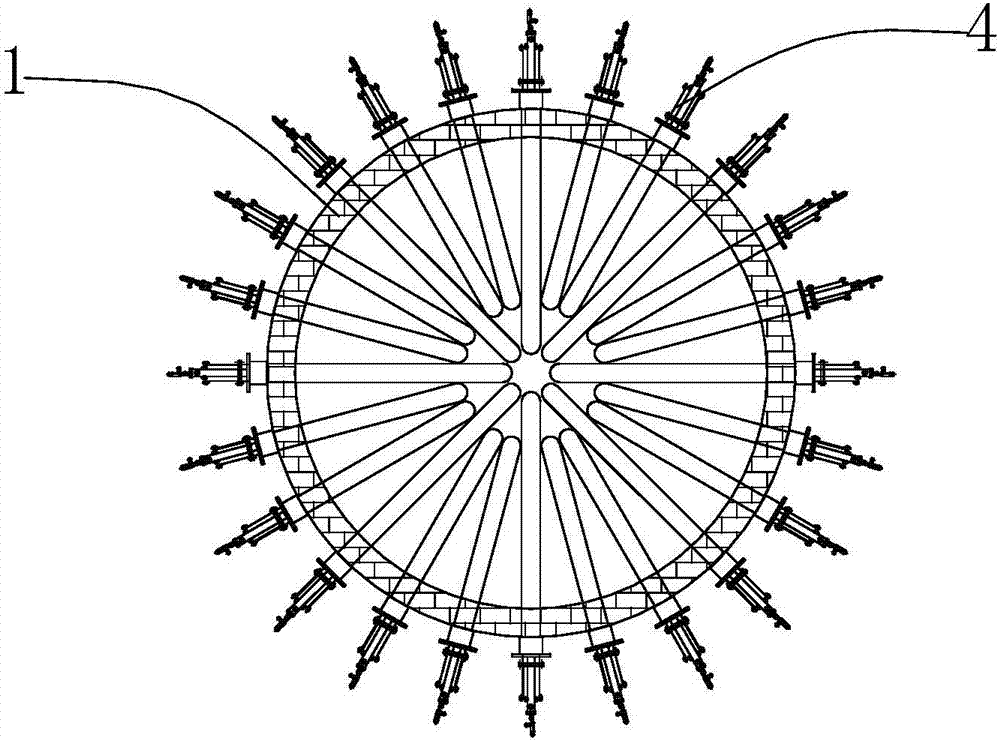

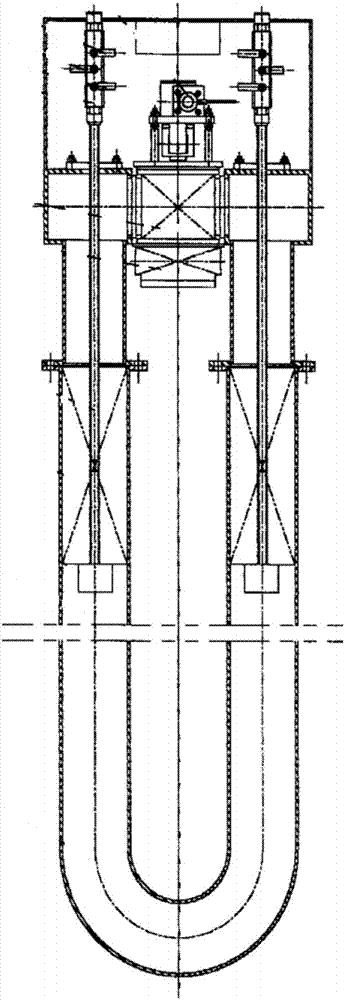

[0024] Such as figure 1 with figure 2 As shown, a downdraft radiant tube biomass pyrolysis charcoal furnace includes a furnace body 1 for pyrolysis carbon production, and a raw material bin 2 for containing raw materials is installed on the top of the furnace body 1. The raw material bin 2 and the top of the furnace body 1 is provided with a feeder 3 for feeding the raw materials in the raw material bin 2 into the furnace body 1, and the furnace body 1 is evenly arranged with a feeder 3 for heating the raw materials entering the furnace body. The regenerative radiant tube burner 4 of the solution, the lower end of the furnace body 1 is respectively provided with a gas collection port 5 for collecting gas products and a charcoal outlet 6 for outputting charcoal products, and the charcoal outlet 6 is connected to the The charcoal product is transported out of the charcoal conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com