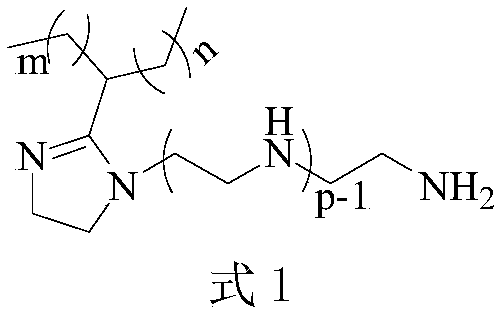

A branched long-chain fatty acid-based imidazoline extractant and its preparation method and application

A long-chain fatty acid and imidazoline-based technology, which is applied in the field of branched long-chain fatty acid-based imidazoline extractant and its preparation and application, can solve the problems of short phase separation time, stripping ability, harsh process conditions, and low exchange capacity, etc. problem, to achieve the effect of shortening the phase separation time, strong extraction ability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In a 500mL three-necked flask equipped with a stirrer, a reflux condenser, a thermometer, and a water separator, add 1.0 mol of isooctanoic acid, 1.2 mol of diethylenetriamine, and an appropriate amount of nickel oxide solid catalyst. Heat with an oil bath, start the stirrer, carry out heating and reflux stirring reaction at normal pressure, and start timing when the reaction reaches the set temperature. The reaction was carried out at a reaction temperature of 160° C. for 3 hours, 180° C. for 3 hours, and 200° C. for 3 hours. After the reaction is finished, after solid-liquid separation, the excess reaction raw materials are removed by washing and distillation, and the unreacted raw materials are recovered and separated to obtain long-chain fatty acid imidazoline. The yield of the long-chain fatty acid-based imidazoline is 93.2%.

Embodiment 2

[0057] In a 500 mL three-neck flask equipped with a stirrer, a reflux condenser, a thermometer, and a water separator, add 0.5 mol of isohexadecanic acid and 3.0 mol of diethylenetriamine to recover the recovered nickel oxide catalyst. Heat with an oil bath, start the stirrer, carry out heating and reflux stirring reaction at normal pressure, and start timing when the reaction reaches the set temperature. The reaction was carried out at a reaction temperature of 160° C. for 3 hours, 180° C. for 3 hours, and 200° C. for 3 hours. After the reaction is finished, after solid-liquid separation, the excess reaction raw materials are removed by washing and distillation, and the unreacted raw materials are recovered and separated to obtain long-chain fatty acid imidazoline. The yield of the long-chain fatty acid-based imidazoline is 94.3%.

Embodiment 3

[0059] In a 500 mL three-necked flask equipped with a stirrer, reflux condenser, thermometer, and water separator, add 0.5 mol of isostearic acid, 3.0 mol of diethylenetriamine, and an appropriate amount of cobalt oxide catalyst. Heat with an oil bath, start the stirrer, carry out heating and reflux stirring reaction at normal pressure, and start timing when the reaction reaches the set temperature. The reaction was carried out at a reaction temperature of 160° C. for 3 hours, 180° C. for 3 hours, and 200° C. for 3 hours. After the reaction is finished, after solid-liquid separation, the excess reaction raw materials are removed by washing and distillation, and the unreacted raw materials are collected step by step to obtain long-chain fatty acid imidazoline. The yield of the long-chain fatty acid-based imidazoline is 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com