Triphenylamine-Benzothiophene Organic Small Molecule Hole Transport Materials and Their Applications

A hole transport material, benzothiophene technology, applied in the field of solar cell materials, can solve problems such as poor stability, and achieve the effects of improving stability, broadening the molecular conjugated system, and achieving outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

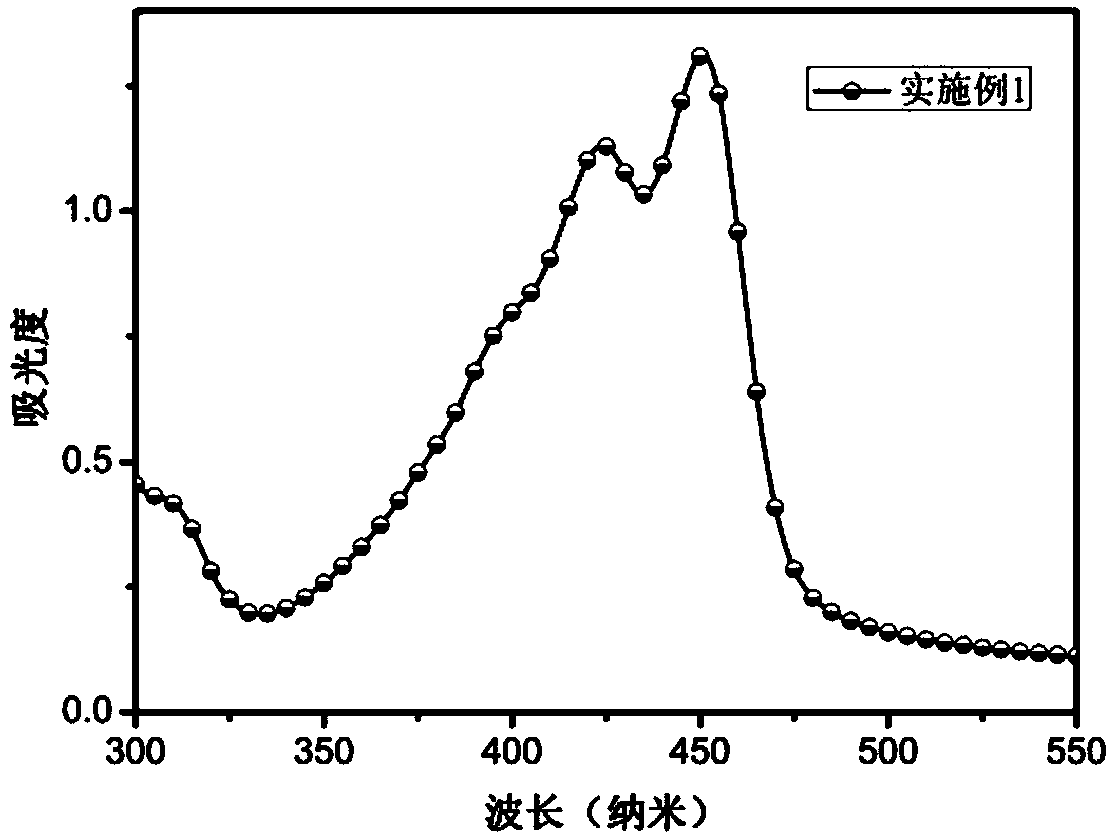

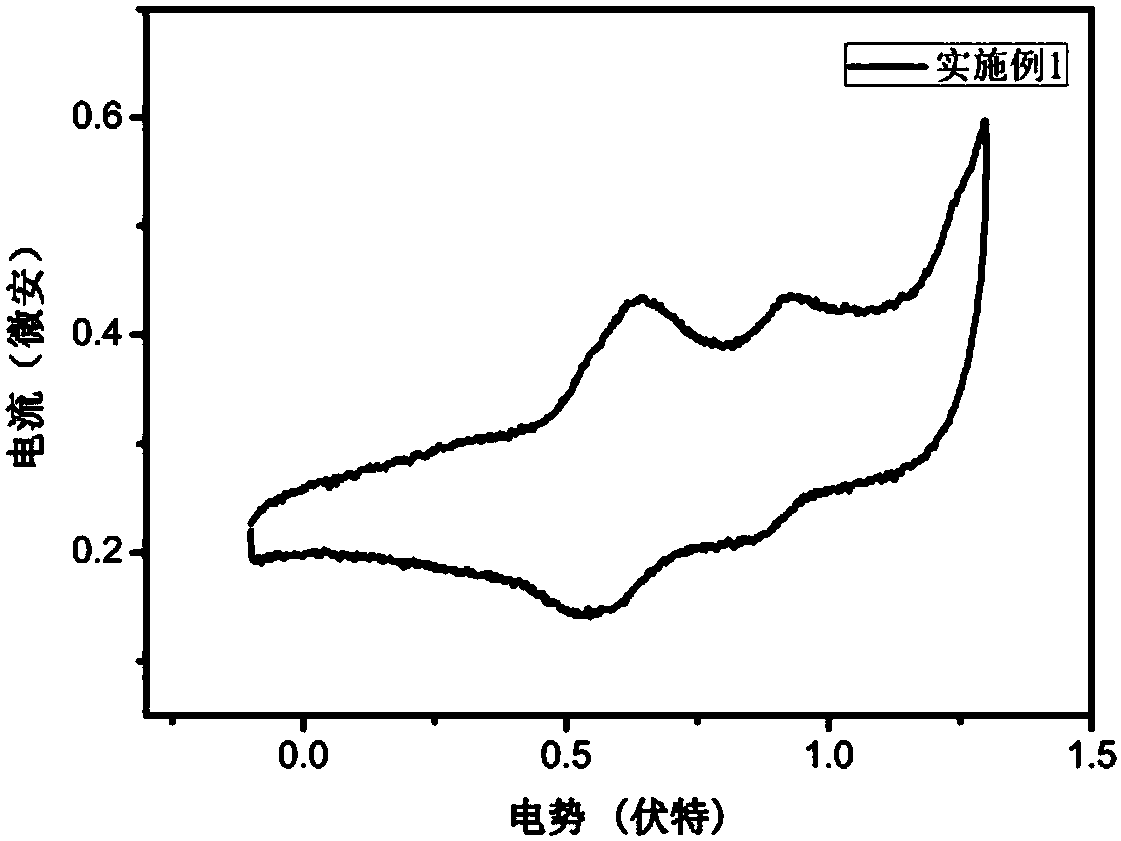

[0046] Synthesis of triphenylamine-benzothiophene organic small molecule hole transport material with structural unit of formula II.

[0047] A kind of triphenylamine-benzothiophene organic small molecule hole transport material whose chemical structural formula is II, its synthetic route is as follows:

[0048]

[0049] Synthesis of intermediate (2):

[0050] Add 2.2g of compound 1, 1.4g of zinc powder and 30mL of water into a 100mL three-neck flask, then add 6g of NaOH, and heat the mixture under reflux for 1h. Then, add 5.0g n-hexane bromide and equivalent catalyst tetrabutylammonium bromide (Bu 4 NBr), the reaction was heated to reflux for 6h. The mixture was poured into ice water, extracted twice with 200 mLTHF, the organic phase was dried with anhydrous magnesium sulfate, and the solvent was removed by rotary evaporation, and the initial product was recrystallized with absolute ethanol to obtain white crystals with a yield of 80%.

[0051] NMR characterization data...

Embodiment 2

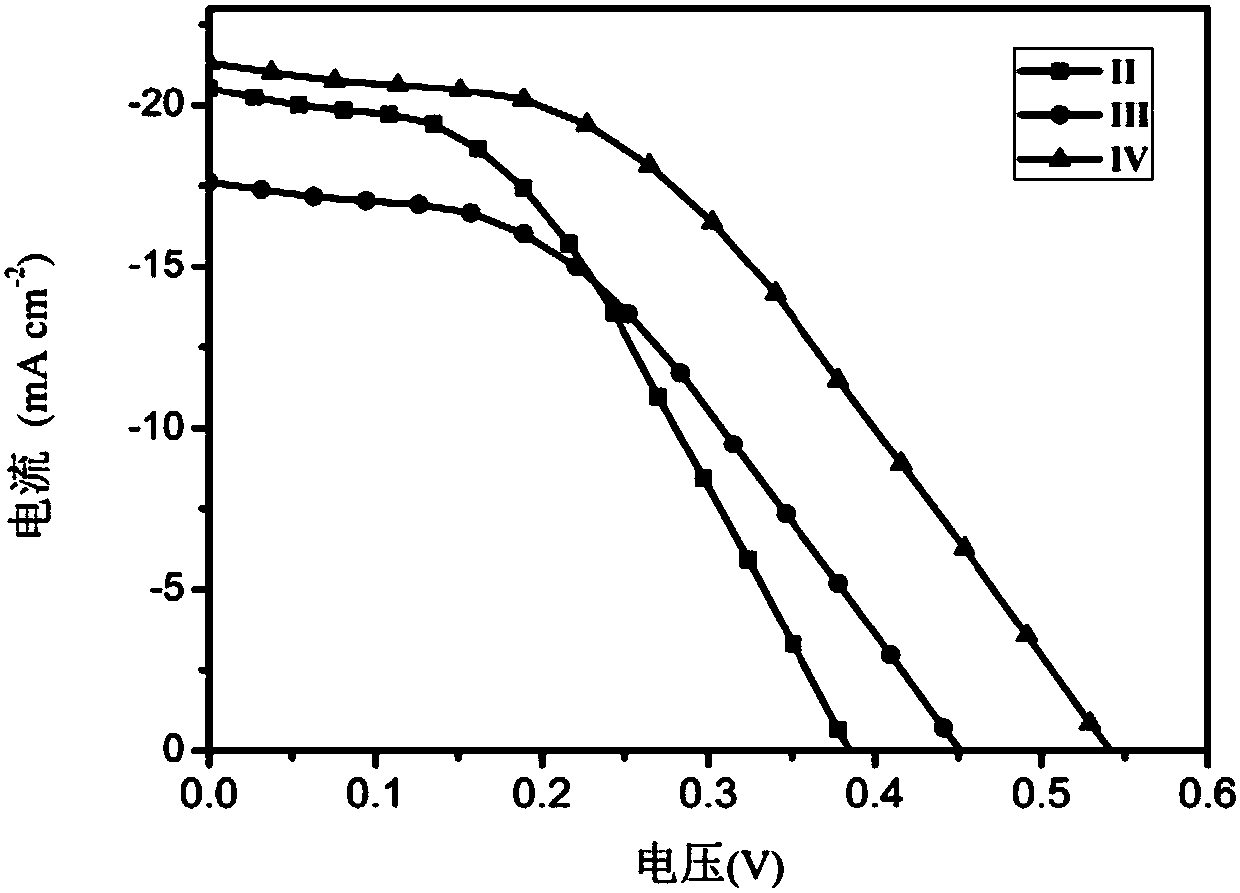

[0074] Synthesis of triphenylamine-benzothiophene organic small molecule hole transport material with chemical structure III.

[0075] A chemical structural formula triphenylamine-benzothiophene organic small molecule hole transport material, the synthesis route is as follows:

[0076]

[0077] Synthesis of intermediate (6):

[0078] Add 10g of 4-iodophenol, 8.9g of isooctane bromide, 19g of potassium carbonate and 150mL of DMF into a 250mL three-neck reaction flask, under nitrogen protection, and stir at reflux for 12h at 120°C. Then the mixture was poured into 1M NaOH aqueous solution, extracted with dichloromethane, the organic liquids were combined, dried over anhydrous magnesium sulfate, and filtered. The solvent was distilled off by rotary evaporation, and the crude product was separated and purified by column chromatography to obtain a colorless liquid with a yield of 53%.

[0079] NMR characterization data of intermediate (6):

[0080] 1 H NMR (CDCl 3 ,500MHz),...

Embodiment 3

[0102] Synthesis of triphenylamine-benzothiophene organic small molecule hole transport material with chemical structure IV.

[0103] A triphenylamine-benzothiophene organic small molecule hole transport material of chemical structural formula IV, its synthetic route is as follows:

[0104]

[0105] Synthesis of intermediate (10):

[0106] Dissolve 5.7 g of monomer M3 and 2.2 g of compound 9 in 45 mL of toluene, then add 2M K 2 CO 3 (12mL) aqueous solution, nitrogen protection, add 0.1mg catalyst Pd (PPh 3 ) 4 , The reaction was vigorously stirred at 110°C for 24h. The mixture was cooled to room temperature, extracted with dichloromethane, the organic layer was dried over anhydrous magnesium sulfate, the solvent was evaporated under reduced pressure, and purified by column chromatography to obtain intermediate 10 with a yield of 64%.

[0107] NMR characterization data of intermediate (10):

[0108] 1 H NMR (400MHz, CDCl 3 ,ppm): δ8.75(s 2H),7.80(d,1H),7.74(d,1H),7.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com