OFDR (optical frequency domain reflection)-based hollow optical fiber continuous liquid level sensing device and measurement method

A technology of hollow optical fiber and sensing device, which is applied in the direction of liquid/fluid solid measurement, measuring device, lubrication indicating device, etc. It can solve the problems of low precision, limited measurement range and low precision, and achieve the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

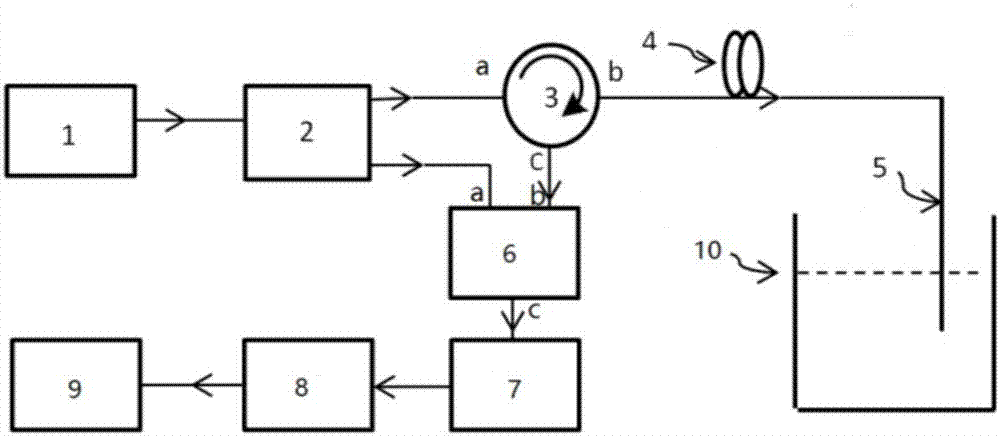

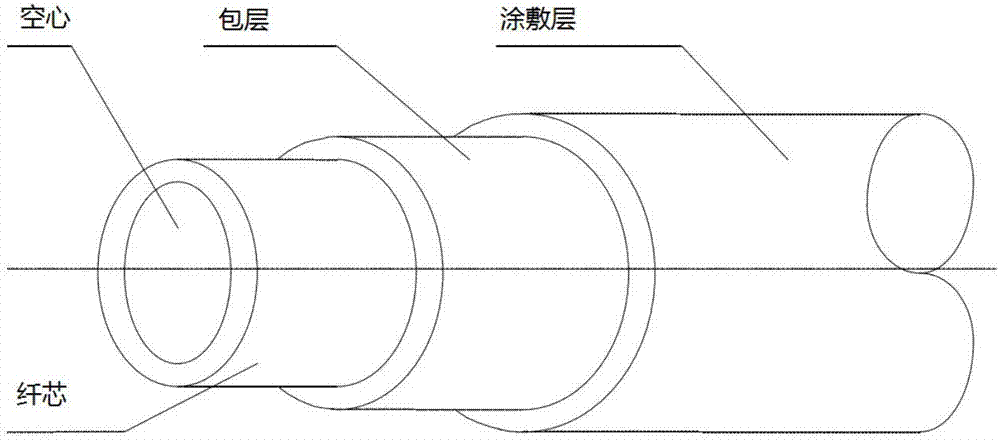

[0040] OFDR-based hollow fiber continuous liquid level sensing device, including linear sweep laser 1, fiber beam splitter (50:50) 2, fiber circulator 3, single-mode fiber 4, hollow fiber 5, fiber coupler (1x2) 6. Photodetector 7, data acquisition card 8 and computer 9.

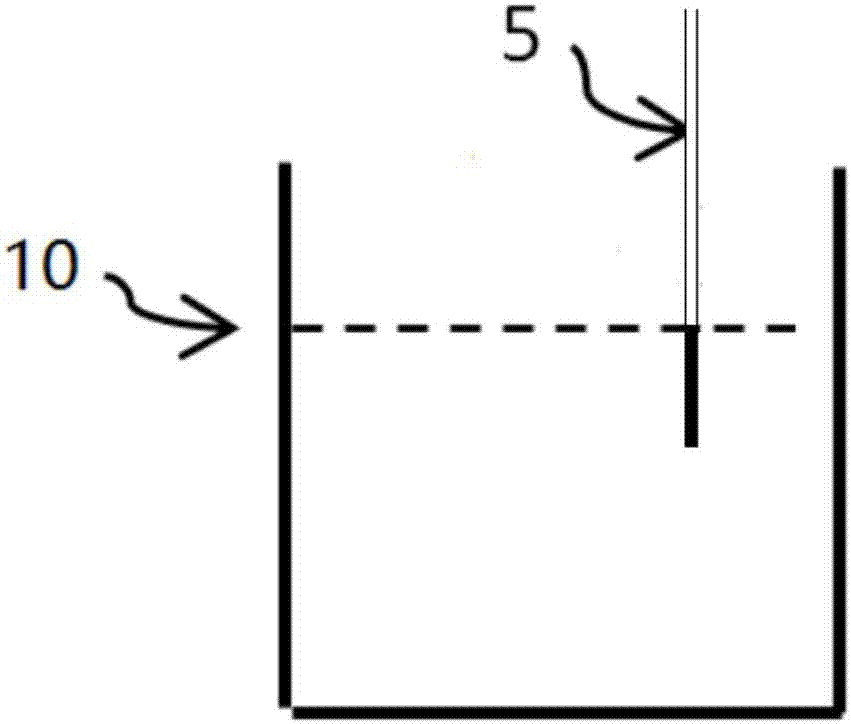

[0041] The linear scanning laser 1 is connected to the input end of the optical fiber beam splitter (50:50) 2, and the output end of the optical fiber beam splitter (50:50) is respectively connected to the a port of the optical fiber circulator 3 and the optical fiber coupler (1x2) 6 a port connection. The b port of the optical fiber circulator 3 is connected to the single-mode optical fiber, and the c port is connected to the b port of the fiber coupler (1x2) 6 . The single-mode fiber 4 is connected to the hollow fiber 5 . The hollow optical fiber 5 is placed in the container conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com