Method for detecting lactic acid and butyric acid in tobacco feed liquid and feed liquid dewatering device

A technology of tobacco and feed liquid, which is applied in the field of analytical chemistry, can solve the problems of incomplete methylation reaction, affect the test results, affect the methylation effect, etc., achieve complete methylation reaction, reduce costs, and improve product safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

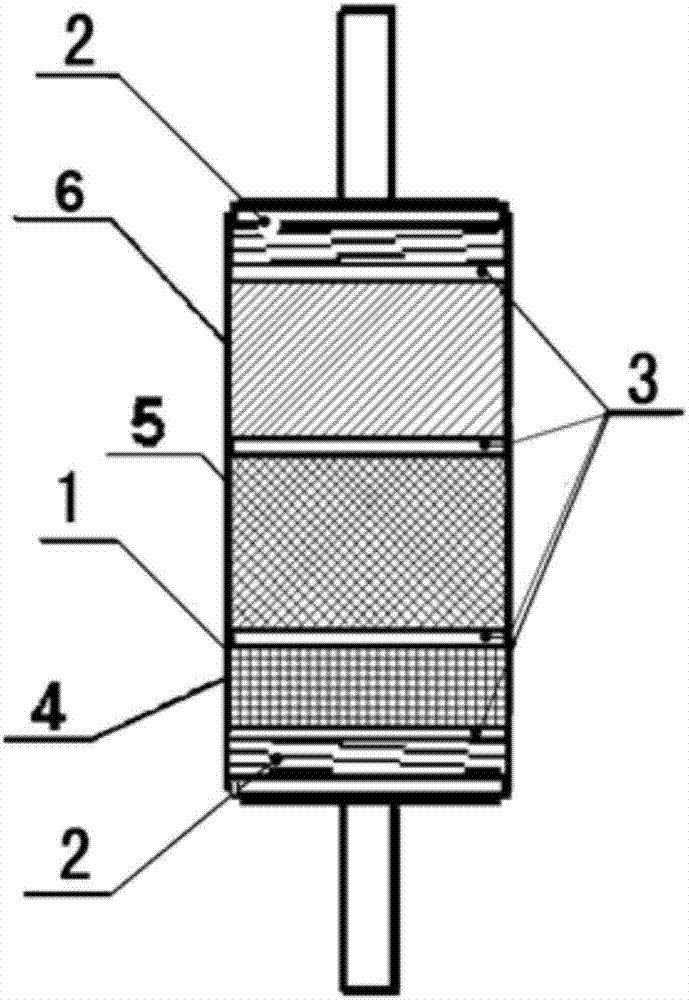

[0031] A solid-phase extraction column for effectively removing moisture from tobacco material liquid, including a column cavity and a column cap, four sieve plates are arranged in the column cavity, and an independent space is formed between two adjacent sieve plates to separate the column cavity It is divided into three relatively independent packing chambers, and each packing chamber is filled with different packing materials, from top to bottom: polyacrylic acid superabsorbent resin, anhydrous sodium sulfate and color-changing silica gel. The volume occupied by polyacrylic acid superabsorbent resin, anhydrous sodium sulfate, and color-changing silica gel packing in the column cavity is approximately 2 / 5, 2 / 5 and 1 / 5. The two ports of the column cavity are threaded, and the column cap is a screw cap with corresponding threads. The two are connected by threads and compress the filler in the column cavity. The polyacrylic acid superabsorbent resin in the first layer is an org...

Embodiment 2

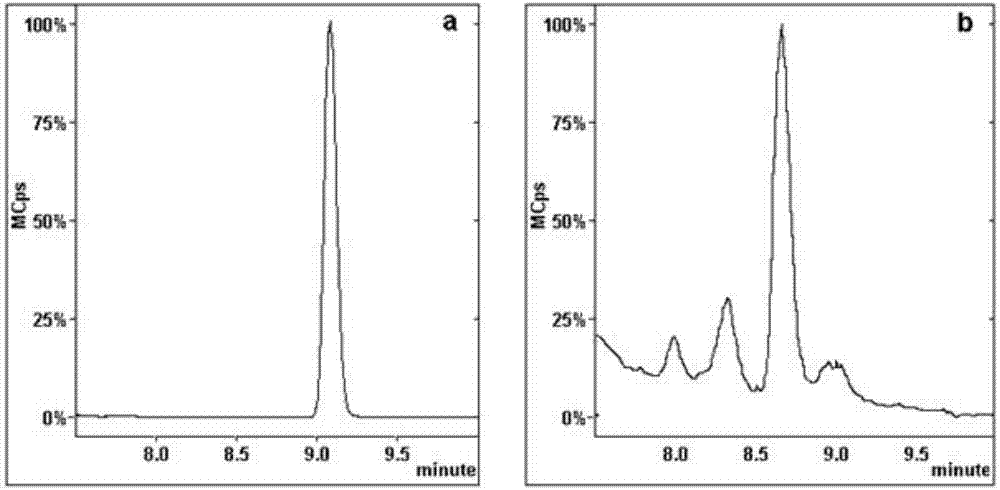

[0038] The measured sample is cigarette lining, take 4.0g of the material liquid, dilute it with 6.0mL of methanol, and pass the diluent through the solid-phase extraction column described in Example 1 at a flow rate of 15mL / min, and then use 12mL of methanol Elute the solid-phase extraction column; combine the tobacco material liquid sample and methanol eluate after passing the column into a glass bottle. Add 1.6 mL of concentrated sulfuric acid to the combined solution, and seal the esterification reaction in a water bath at 70°C for 35 min. Take 1.0mL of methyl esterified solution to a liquid-liquid extraction device, add 1.0mL of dichloromethane, shake fully, then add 1.0mL of water to shake for 2-4min, and let stand for 20-40min. Then push down the piston rod of the liquid-liquid extraction device, stratify at the capillary mouth, then suck out (or pour out) the upper layer, and the lower layer (dichloromethane layer) is filtered with a 0.45 μm organic filter membrane, an...

Embodiment 3

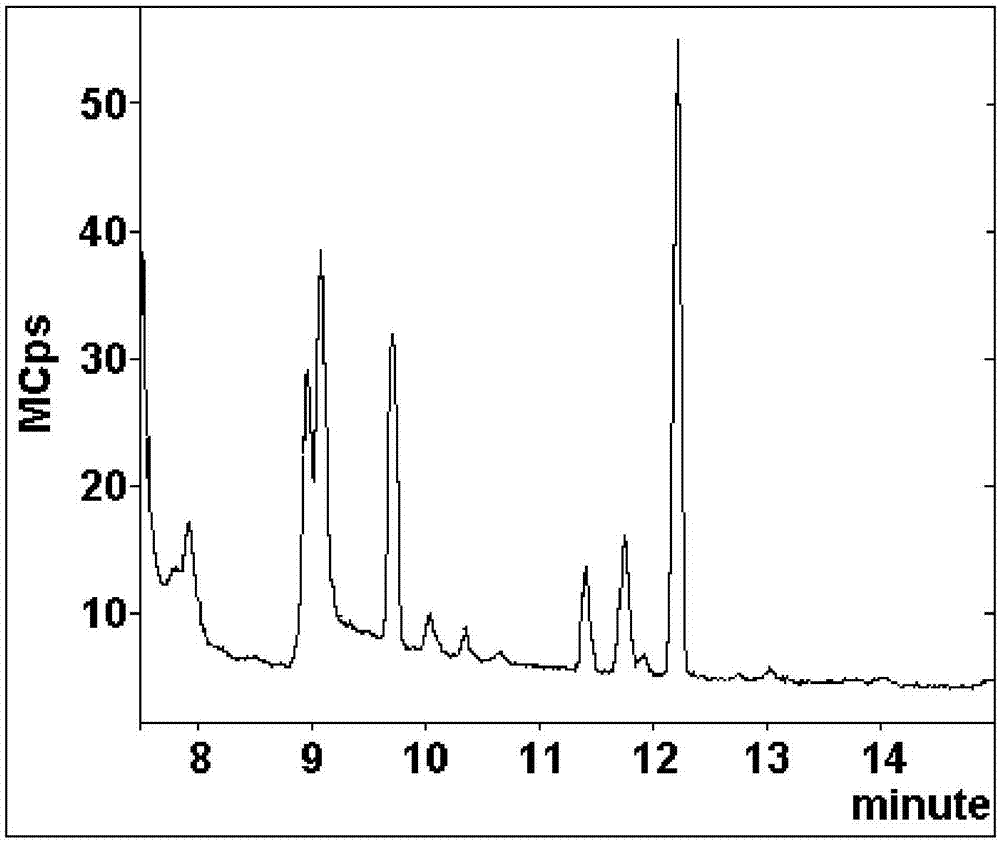

[0042] The measured sample is the Rosa roxburghii extract, 4.0g of the feed liquid is diluted with 6.0mL of methanol, and the diluted solution passes through the solid-phase extraction column described in Example 1 at a flow rate of 15mL / min, and after passing the column, use 4mL of Methanol eluted solid-phase extraction column; combined the tobacco material liquid sample and methanol eluate after passing through the column into a glass bottle. Add 1.6 mL of concentrated sulfuric acid to the combined solution, and seal the esterification reaction in a water bath at 70°C for 35 min. Take 1.0mL of methyl esterified solution to a liquid-liquid extraction device, add 1.0mL of dichloromethane, shake fully, then add 1.0mL of water to shake for 2-4min, and let stand for 20-40min. Then push down the piston rod of the liquid-liquid extraction device, stratify at the capillary mouth, then suck out (or pour out) the upper layer, and the lower layer (dichloromethane layer) is filtered wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com