Flat-plate multi-chamber gap discharge electrode

A discharge electrode, multi-chamber technology, applied in circuits, spark gaps, electrical components, etc., can solve the problems of failure of lightning protection function, change of lightning protection characteristics of multi-gap arresters, damage to multi-gap structure, etc., to avoid electrical aging, The effect of ensuring the correct lightning protection function, ensuring the quality and safety of power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

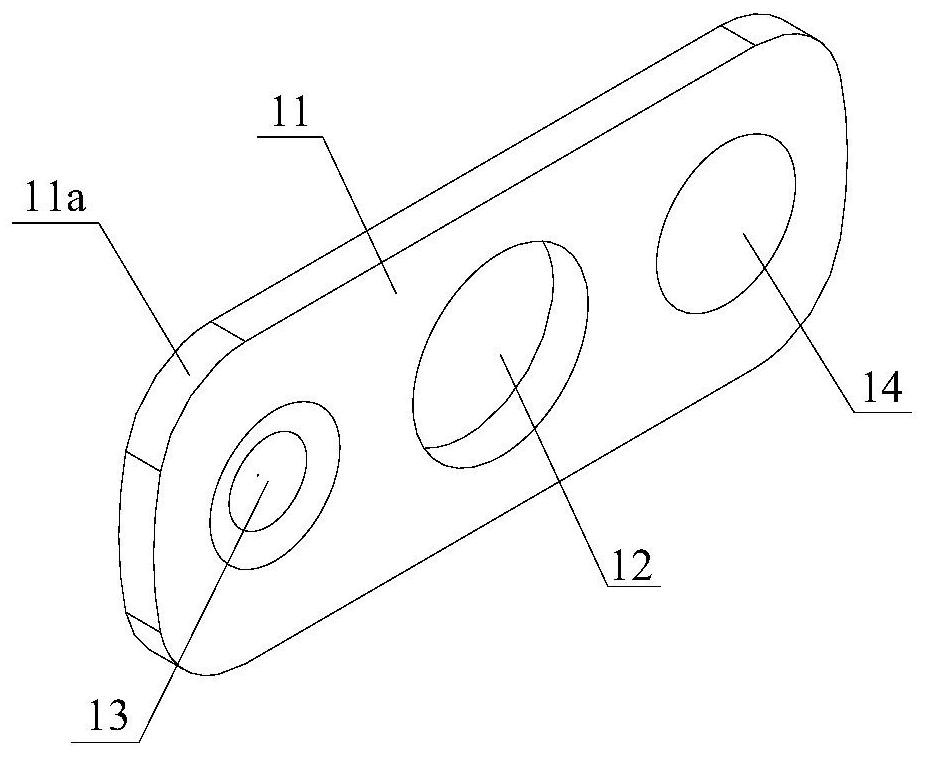

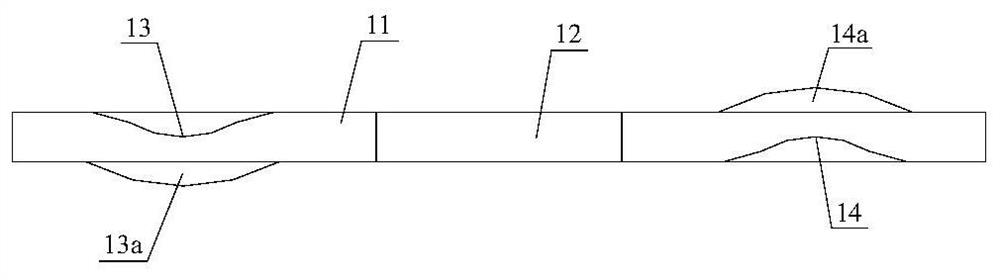

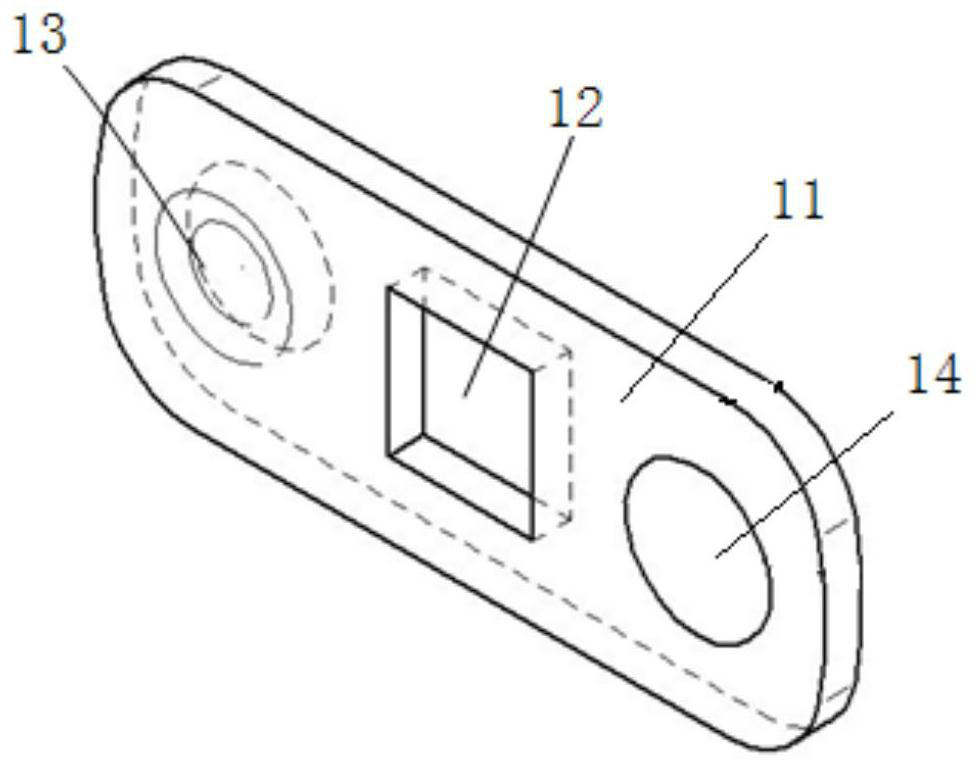

[0022] Such as figure 1 The flat plate multi-chamber gap discharge electrode includes a cuboid flat plate 11, a through-center fixing hole 12 provided on the center of gravity of the cuboid flat plate 11, a first discharge terminal 13 arranged at one end of the cuboid flat plate 11 and the other end of the cuboid flat plate 11. The second discharge end 14, and the first discharge end 13 and the second discharge end 14 are symmetrically distributed on both sides of the through-core fixing hole 12. In this embodiment, the cuboid flat plate 11 is made of a metal material with good conductivity. At the same time, all the edges and corners of the cuboid flat plate 11 are rounded to form an arc surface 11a to ensure that the edges of the cuboid flat plate 11 are smooth, which can effectively avoid electrical aging or even insulation breakdo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com