Single chip integrated acoustic surface wave filter component

A surface acoustic wave filtering and monolithic integration technology, applied in the field of microelectronics, can solve the problems of large volume and weight, incompatible with the miniaturization and portability of electronic devices and systems, and reduce the switching performance of the filter unit gating circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the drawings and descriptions of the drawings.

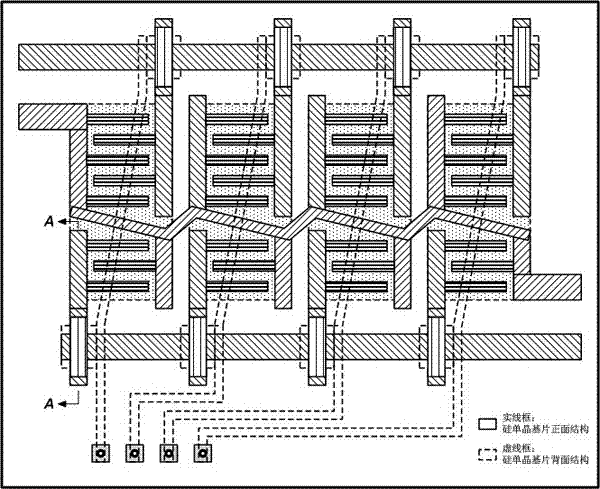

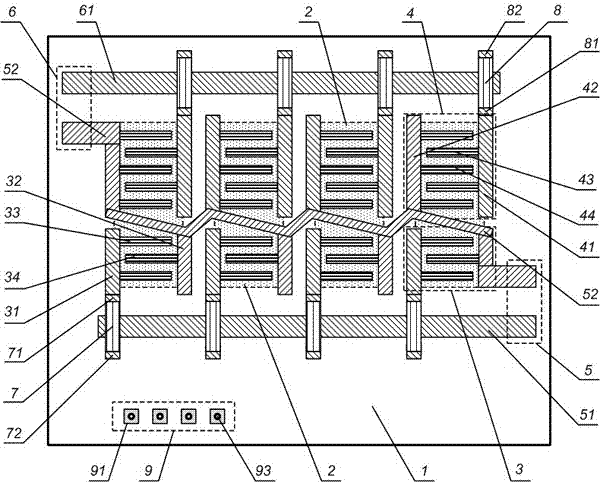

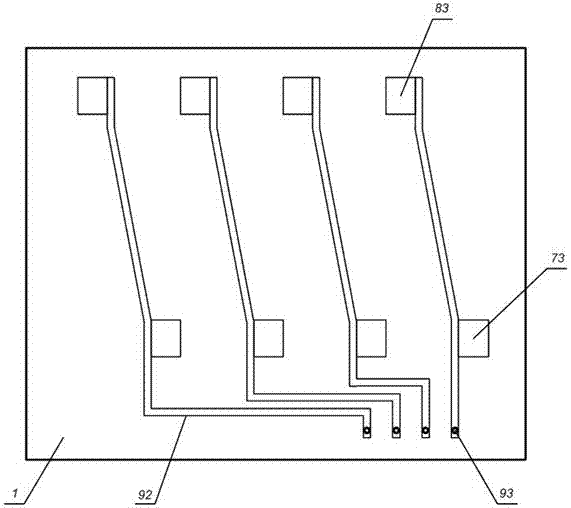

[0052] Such as figure 1 , 2 , 3 and 4 shows the structure of a monolithic integrated 4-unit surface acoustic wave filter component, including:

[0053] Silicon single crystal substrate 1, 4 zinc oxide piezoelectric thin film regions 2 fabricated on the front side of silicon single crystal substrate 1, 4 surface acoustic wave filter units respectively fabricated on the 4 zinc oxide piezoelectric thin film regions 2, 1 A surface acoustic wave filter unit includes an input IDT 3 and an output IDT 4;

[0054] 4 input signal main electrodes 51 made outside the input IDT 3, output signal main electrodes 61 made outside the 4 output IDTs 4, the input IDT 3 and the output IDT The grounding total electrode 52 made between the 4 input ground terminal bus electrodes 32 and the 4 output ground terminal bus electrodes 42, the input signal general electrode 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com