Packaged branded noodle processing method with radio frequency sterilization

A technology of baking noodles and radio frequency, which is applied in packaging, transportation packaging, packaging sterilization, etc., can solve problems such as inability to guarantee product quality, and achieve the effects of high efficiency and environmental protection in the production process, reduction of energy consumption, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, under different conditions, the temperature rise of the radio frequency heating treatment packaging surface

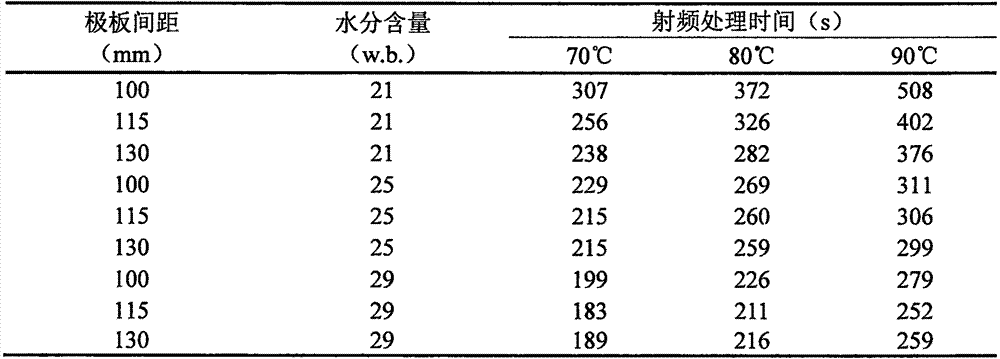

[0021] For the packaging surface with moisture content of 21%, 25% and 29%, radio frequency heating was carried out at the distance between the plates of 100, 115 and 130mm. The time required for heating to 70, 80 and 90°C is shown in Table 1. This provides a comparison of processing time for controlling materials to reach different final temperatures during radio frequency sterilization.

[0022] Table 1 Radio frequency heating treatment material temperature time

[0023]

Embodiment 2

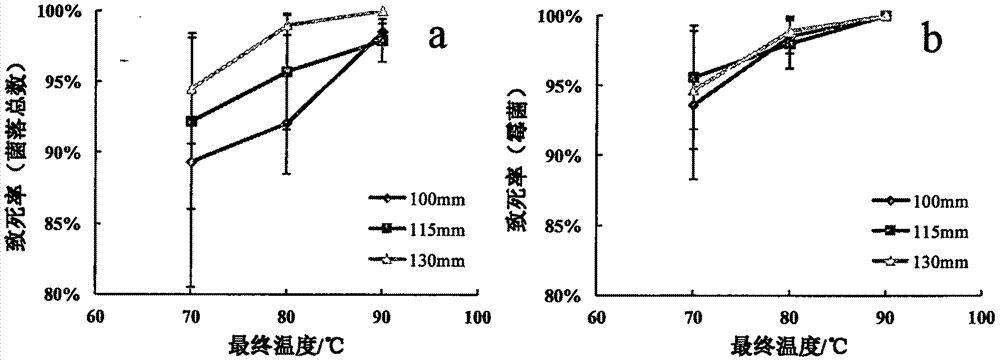

[0024] Embodiment 2, the influence of pole plate spacing and material heating temperature on sterilization effect

[0025] The original bacteria content is 4.2×10 4 ±1.2×10 4 (total number of colonies) and 2.3×10 3 ±0.4×10 3 (mold), the baking surface with a moisture content of 29% was used to carry out the sterilization test with different plate spacing and temperature. figure 1 It is the change of the total number of drops and the lethality of mold with the material heating temperature (70, 80 and 90 ℃) when the surface is sterilized by radio frequency at the distance between the plates of 100, 115 and 130 mm. The results showed that the total number of colonies and the lethality rate of mold both increased with the increase of the final temperature under the three plate spacing. When the distance between the plates is 100mm, when the final temperature is 70°C, the total number of colonies and the lethality rate of mold on the packaging surface are 89.3%±8.8% and 93.6%±5...

Embodiment 3

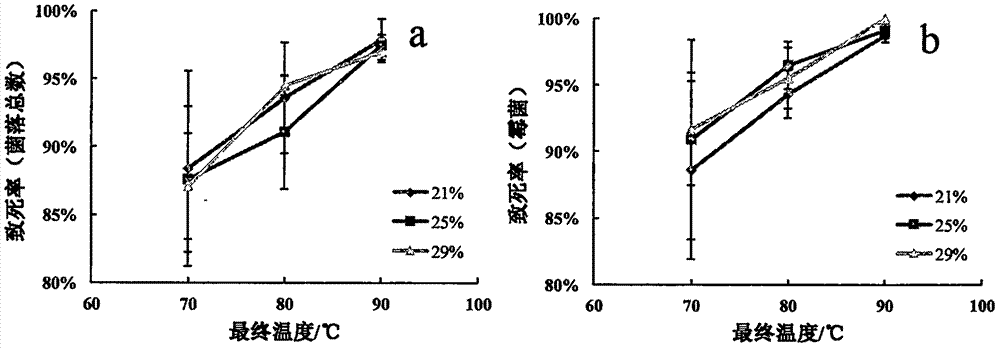

[0026] Embodiment 3, the influence of moisture content and material heating temperature on bactericidal effect

[0027] The original bacteria content is 3.7×10 4 ±4.0×10 3 (total number of colonies) and 1.9×10 3 ±0.6×10 3 (Mold) packaged surface was used to carry out the sterilization test of moisture content and material heating temperature. figure 2 It is to carry out radio frequency heating under the pole plate spacing of 115mm, and the moisture content is 21%, 25% and 29% The change of the total number of colonies and mold lethality of the surface with the material temperature (70, 80 and 90 ℃). The results showed that under different moisture content, the total number of bacterial colonies and the lethality rate of the mold increased with the increase of the final temperature. When the final temperature was 70°C, the total number of colonies and the lethality rate of the mold on the baked noodles with a moisture content of 25% were 87.6%±5.4% and 90.9%±7.5%, respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com