Seedling substrate for promoting rooting of hylocereus undulatus and preparation method of seedling substrate

A technology for raising seedling substrate and dragon fruit, applied in the field of agricultural planting, can solve the problems of lack of nutrient elements, unsuitable pH, low survival rate, diseases and insect pests, etc., and achieve the effects of improving survival rate and ensuring interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

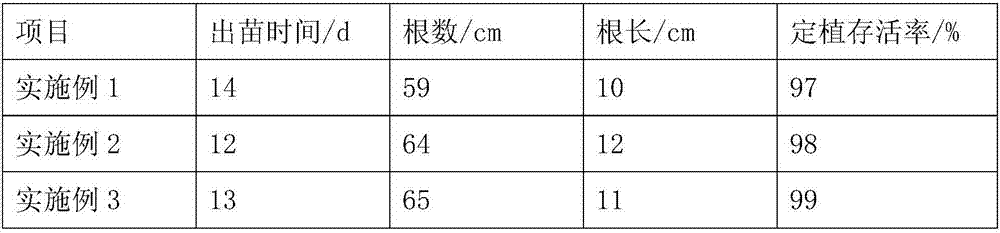

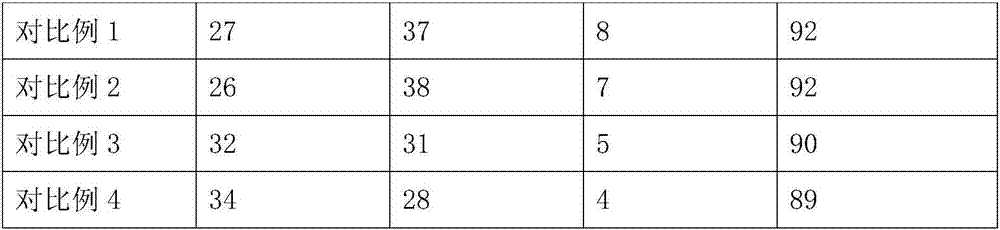

Examples

Embodiment 1

[0029] A kind of seedling-raising matrix that promotes dragon fruit to take root, described seedling-raising matrix is provided with buffer layer, nutrient layer and air-permeable layer from top to bottom, and the thickness ratio of buffer layer, nutrient layer and air-permeable layer is 1:4:1;

[0030] The upper layer of the buffer layer is sterilized sugarcane leaves, the lower layer is medium sand, and the thickness ratio of sterilized sugarcane leaves and medium sand is 4:1;

[0031] The nutrient layer is made of the following raw materials in terms of parts by weight: 20 parts by weight of Cyperus cyperi, 10 parts of Caulis Spatholobus, 10 parts of blue cloth, 6 parts of Xiangmu, 6 parts of Alisma, 10 parts of Bletilla striata 8 parts of Chinese herbal medicine, 8 parts of hawthorn, 10 parts of Prunella vulgaris, 10 parts of lamp core, 8 parts of Tribulus terrestris, 4 parts of licorice, 5 parts of medicinal dregs, 5 parts of peanut shells, 5 parts of pine bark, corn 5 ...

Embodiment 2

[0040] A kind of seedling-growing substrate that promotes dragon fruit to take root, described seedling-growing substrate is provided with buffer layer, nutrient layer and air-permeable layer from top to bottom, and the thickness ratio of buffer layer, nutrient layer and air-permeable layer is 1:5:2;

[0041] The upper layer of the buffer layer is sterilized sugarcane leaves, the lower layer is medium sand, and the thickness ratio of sterilized sugarcane leaves and medium sand is 4:1;

[0042] The nutrient layer is made of the following raw materials in parts by weight: 30 parts by weight of Cyperus cyperi, 20 parts of Caulis Spatholobus, 20 parts of blue cloth, 10 parts of fragrant wood, 10 parts of Alisma, 15 parts of bletilla striata 15 parts of Chinese herbal medicine, 15 parts of hawthorn, 15 parts of Prunella vulgaris, 15 parts of lamp wick, 10 parts of Tribulus terrestris, 6 parts of licorice. 15 parts of core, 15 parts of soybean meal, 15 parts of cassava skin, 15 part...

Embodiment 3

[0051] A seedling-growing matrix that promotes pitaya rooting, said seedling-growing matrix is provided with a buffer layer, a nutrient layer and an air-permeable layer from top to bottom, and the thickness ratio of the buffer layer, the nutrient layer and the air-permeable layer is 1:5:1;

[0052] The upper layer of the buffer layer is sterilized sugarcane leaves, the lower layer is medium sand, and the thickness ratio of sterilized sugarcane leaves and medium sand is 4:1;

[0053] The nutrient layer is made of the following raw materials according to the ratio of parts by weight:

[0054] The nutrient layer is made of the following raw materials in terms of parts by weight: 25 parts by weight of Cyperus cyperi, 16 parts of Caulis Spatholobus, 15 parts of blue cloth, 9 parts of fragrant wood, 8 parts of Alisma, 13 parts of bletilla striata 9 parts, 11 parts of hawthorn, 12 parts of Prunella vulgaris, 13 parts of lamp core, 9 parts of Tribulus terrestris, 9 parts of Chinese ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com