Manufacturing method of light-sensitive decorative-pattern-variable fabric

A manufacturing method and fabric technology, applied in the field of fabric manufacturing, can solve the problems of inability to wash, affect shade, poor color fastness to soaping, etc., and achieve the effects of less pollution hazard, high color uniformity, and improved hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

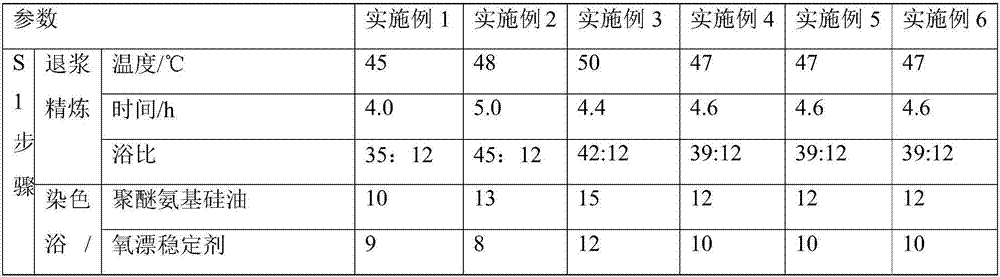

[0041] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0042] A method for manufacturing an optically variable pattern fabric, comprising the steps of:

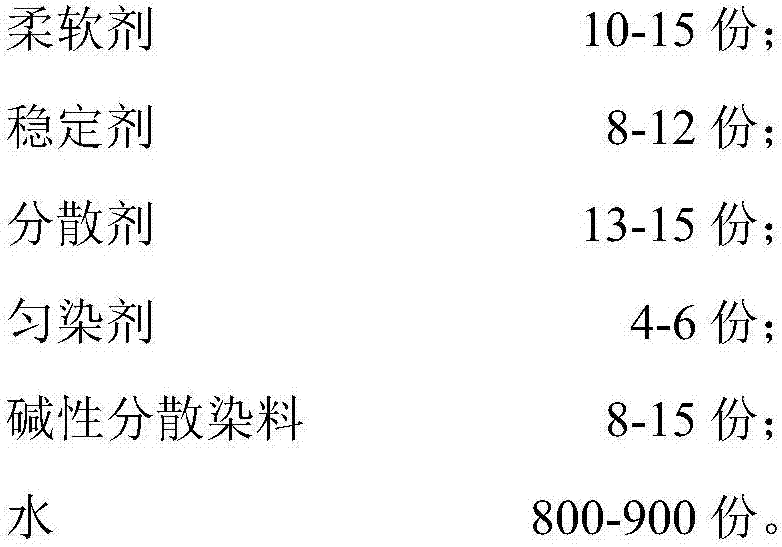

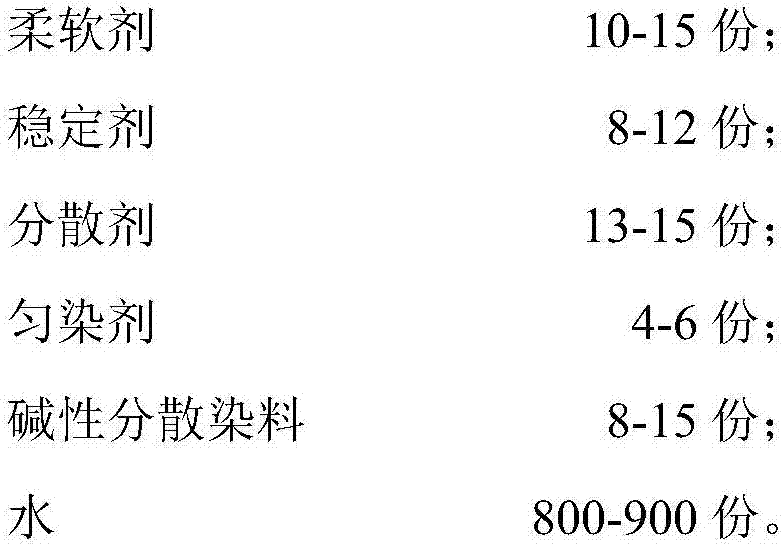

[0043] S1 gray cloth dyeing: put the gray cloth into the flat cylinder, and pass steam into the flat cylinder, then add desizing and refining agent for desizing and refining treatment, transport the gray cloth to the dyeing machine, after the cloth feeding is completed, add to the dyeing bath Softener, stabilizer, dispersant, leveling agent, basic disperse dye and water, after the dye is added and mixed completely, start to heat up to 105-145°C, keep warm for 45-60min, and cool down to ≤60°C;

[0044] S2 Removal of floating color: Wash the gray cloth by one or more methods of enzyme water washing, stone washing, and enzyme stone washing until the pH val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com