Composite buffering agent for acidification in oil exploitation of low-permeability oil field

A technology of oil extraction and buffering agent, which is applied in the fields of production fluid, earthwork drilling, recycling technology, etc. It can solve the problems of low-permeability reservoirs with insignificant effect, easy to change properties, and difficult to degrade, etc., and achieve excellent corrosion inhibition effect , less environmental pollution, high extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

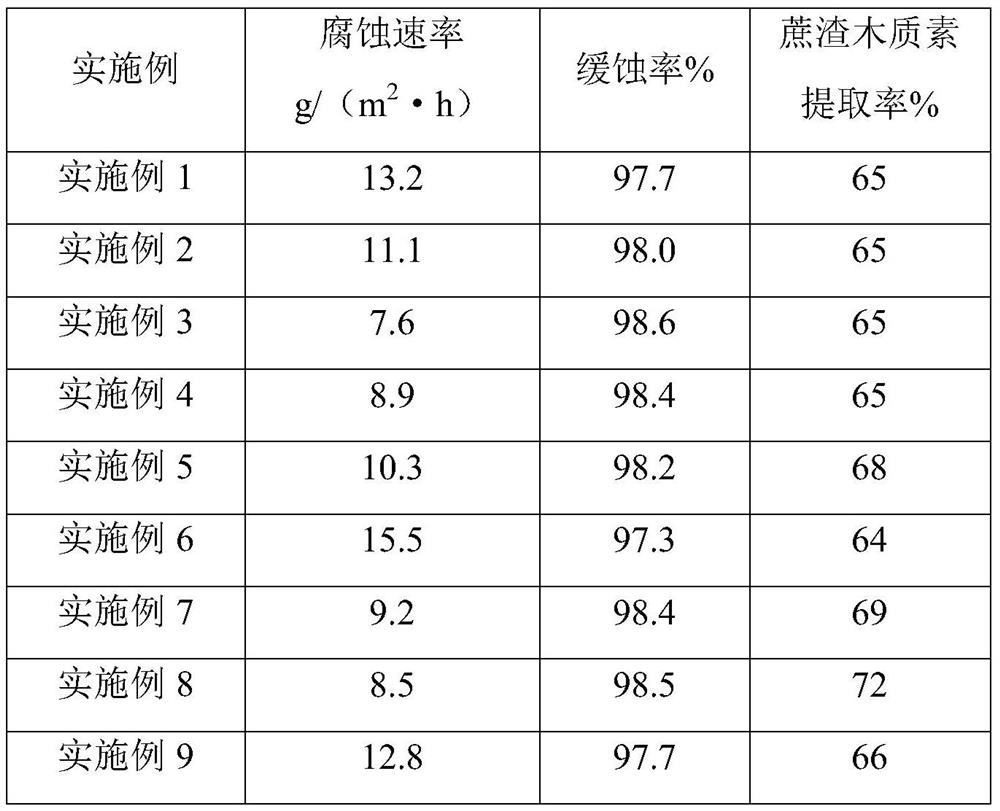

Embodiment 1

[0027] A composite buffer used for acidification of low-permeability oilfield oil extraction, including plant buffer component A, plant buffer component B, modified Mannich base corrosion inhibitor, buffer synergist and organic solvent, Wherein, the raw materials of each component contain 8 parts, 15 parts, 24 parts, 3 parts and 130 parts by weight respectively, and the organic solvent is ethanol with a mass concentration of 75%.

[0028] The raw materials of plant buffer component A are fresh tea seed shells and walnut green peels. The extraction steps of plant buffer component A are: after mixing fresh tea seed shells and walnut green peels in a mass ratio of 3:1, the natural Air-dried, dried to constant weight at 50°C, ground into fine powder and placed in an extractor. The extractor was a commercially available Soxhlet extractor, and an organic solvent 13 times the weight of the plant powder was added at the same time, and the extraction temperature was 85°C. , the extract...

Embodiment 2

[0037] This example is basically the same as Example 1, except that the mass fractions of the raw materials of each component in the composite buffer are different.

[0038] A composite buffer used for acidification of low-permeability oilfield oil extraction, including plant buffer component A, plant buffer component B, modified Mannich base corrosion inhibitor, buffer synergist and organic solvent, Wherein, the raw materials of each component are calculated in parts by weight, and the contents are respectively 10 parts, 15 parts, 26 parts, 3 parts and 128 parts, and the organic solvent is ethanol with a mass concentration of 75%.

[0039] The extraction steps of plant buffer component A are as follows: mix fresh tea seed husks and walnut green husks in a mass ratio of 3:1, then air-dry them naturally, dry them at 55°C to constant weight, and grind them into fine powder Put it into the extractor, add an organic solvent 13.5 times the weight of the plant powder at the same tim...

Embodiment 3

[0041] This example is basically the same as Example 1, except that the mass fractions of the raw materials of each component in the composite buffer are different.

[0042] A composite buffer used for acidification of low-permeability oilfield oil extraction, including plant buffer component A, plant buffer component B, modified Mannich base corrosion inhibitor, buffer synergist and organic solvent, Wherein, the raw materials of each component have contents of 12 parts, 16 parts, 22 parts, 2 parts and 124 parts respectively in parts by weight, and the organic solvent is ethanol with a mass concentration of 75%.

[0043] The extraction steps of plant buffer component A are as follows: mix fresh tea seed husks and walnut green husks in a mass ratio of 3:1, then air-dry them naturally, dry them at 60°C to constant weight, and grind them into fine powder Put it into the extractor, add an organic solvent 14 times the weight of the plant powder at the same time, the extraction temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com