Earth covered storage tank system for storing liquefied hydrocarbon at normal temperature and pressure

A technology for liquefied hydrocarbons and storage tanks, which is applied in pressure vessels, fixed-capacity gas storage tanks, and methods of container discharge, etc., can solve the problems of buried storage tanks that should not be too large in volume, high engineering costs, and difficult to construct. Achieve the effect of avoiding water damage or uneven settlement, low construction cost, and low construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

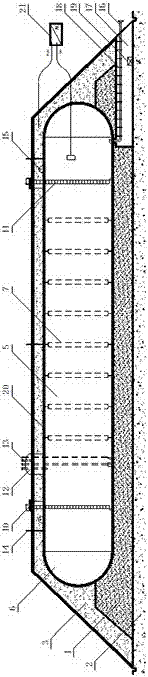

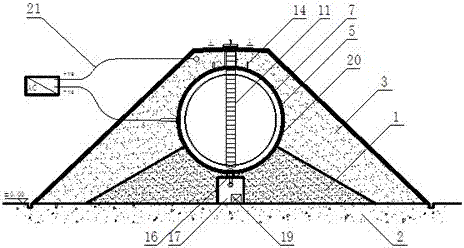

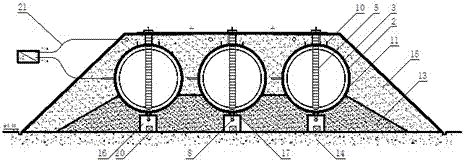

[0035] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as Figure 1-11 shown).

[0036] An earth-covered storage tank system for storing liquefied hydrocarbons under normal temperature and pressure, which includes one or more earth-covered storage tanks arranged side by side. Above the sand bed 1 is a flat ground 2 with uniform settlement, and the outer surface of the storage tank is completely covered by the soil layer 3; the sand bed 1 directly below each storage tank is provided with a tank bottom channel 17 (the tank bottom channel 17 is generally Constructed of concrete or reinforced concrete and normally passable for operation and maintenance);

[0037]The storage tank is a horizontal cylindrical storage tank under normal temperature and pressure, including a cylinder body 5, a spherical head 6, a reinforcement ring 7 in the tank, a manhole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com