Preparation method of pipe cap used for 5G communication high-speed laser TO packaging

A technology of lasers and packaging tubes, which is applied in the field of semiconductor laser packaging components, can solve the problems of low laser coupling efficiency, high cost, and inability to realize a single laser, and achieve the effect of miniaturization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

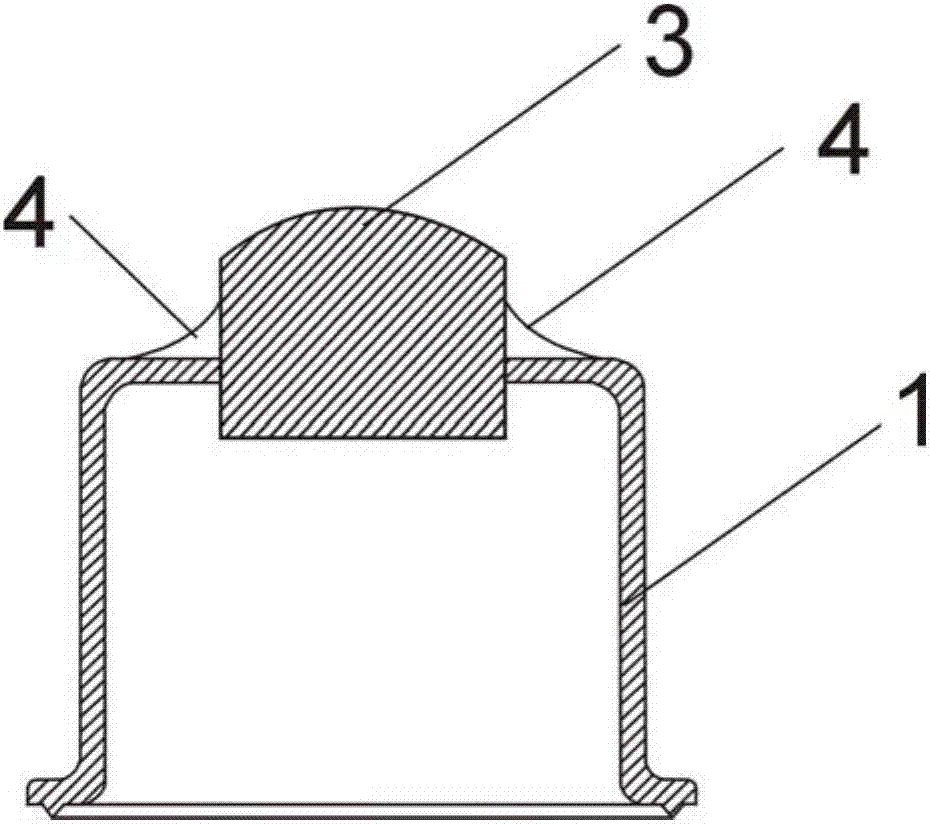

[0021] A kind of preparation method that is used for 5G communication high-speed laser TO package tube cap comprises:

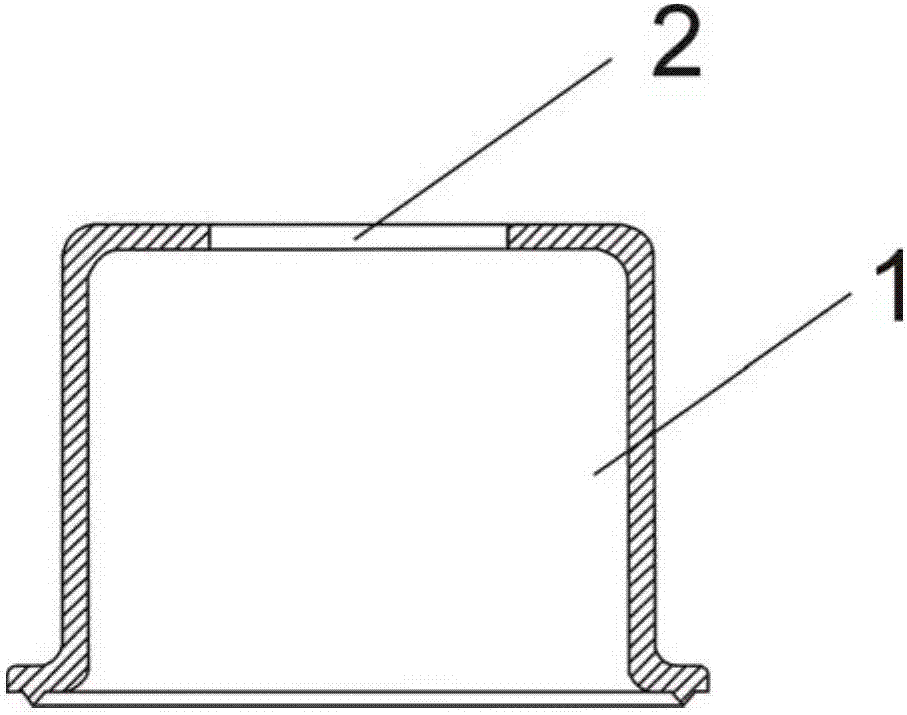

[0022] (1) Preparation of the metal tube shell: the metal alloy is precision stamped and formed, and the nickel is plated with 3-5 microns after degreasing and cleaning;

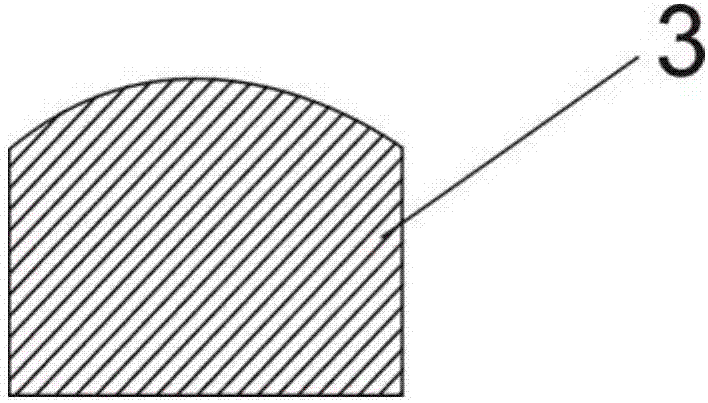

[0023] (2) Preparation of C-Lens: choose glass material with a refractive index of 1.80, process it into a diameter of 1.8±0.01 mm, a height of 1.2±0.01 mm, a radius of curvature of 1.0±0.003 mm, and a slope of 8±0.5 degrees;

[0024] (3), glass-ceramic welding ring, spare;

[0025] (4) Assemble the above materials on the fixture and put them into the atmosphere sintering furnace. The temperature setting parameters of the temperature zone: 100°C-450°C-300°C-100°C, time: 60-90 minutes, atmosphere: oxidation atmosphere.

[0026] temperature zone ℃

RT~100

100~450

450~450

450~300

300~100

100~RT

Time Min

5-10

15-20

15-20

15-20

5-10

5-10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com