Shape memory hydrogel made of 3D printing and application in controlled release preparation thereof

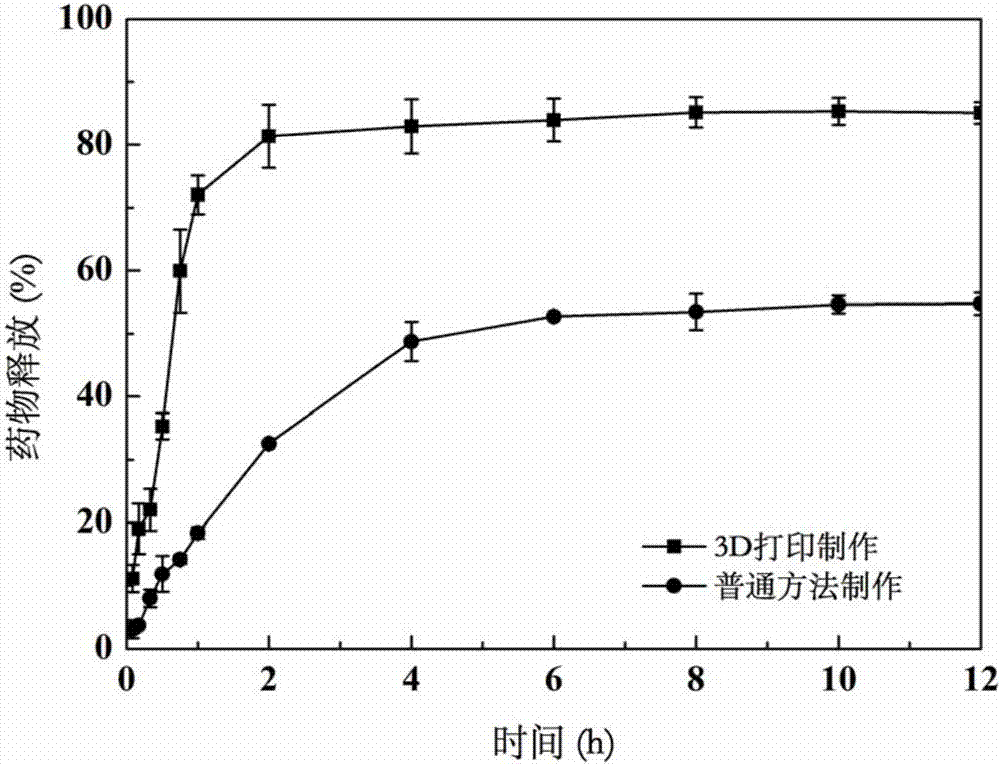

A hydrogel and printing ink technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of insufficient holes and insufficient shape memory function, so as to reduce drug toxicity, avoid degradation and drug efficacy loss , enhance the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a shape memory hydrogel, comprising the following steps:

[0038] (1) Synthetic base hydrogel

[0039] Add the hydrogel material (Pluronic), acryloyl chloride, and triethylamine into dichloromethane, react for 12 hours under ice bath, and react for 12 hours at room temperature, then wash the reaction product with a saturated solution of sodium bicarbonate, and then rotary evaporate The solvent is used to obtain a modified hydrogel material; every 100mL of dichloromethane contains 0.6-13.0g of hydrogel material, 3-6mL of acryloyl chloride, and 3-6mL of triethylamine;

[0040] (2) Preparation of printing ink

[0041] With deionized water as solvent, add the modified hydrogel material (final concentration 0.12g / mL), sodium alginate (final concentration 0.04g / mL) and photoinitiator (2,2-dimethoxy base-2-phenylacetophenone) (final concentration 0.2mg / mL), stir evenly, and put it in a 4°C refrigerator for defoaming.

[0042] (3) 3D model design and l...

Embodiment 2

[0051] A method for preparing a shape memory hydrogel, comprising the following steps:

[0052] (2) Preparation of printing ink

[0053] Using deionized water as a solvent, add the modified hydrogel material (final concentration 0.14g / mL), sodium alginate (final concentration 0.03g / mL) and photoinitiator (2,2-dimethoxy base-2-phenylacetophenone) (final concentration 0.3mg / mL), stir evenly, and put it in a 4°C refrigerator for defoaming.

[0054] Steps (1), (3), (4) are the same as in Example 1.

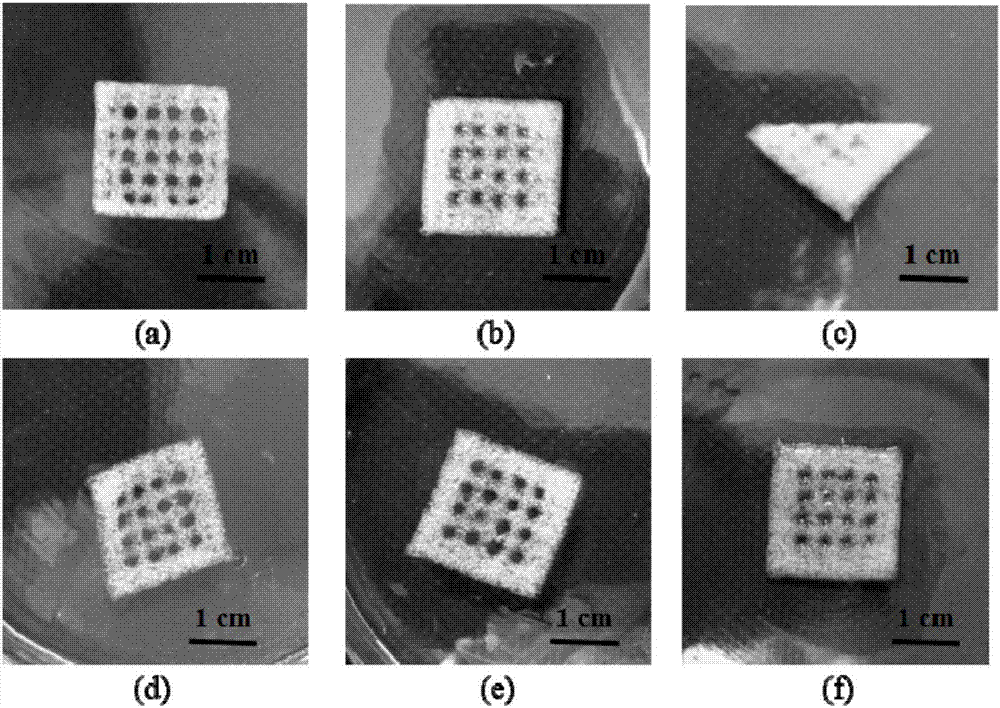

[0055] The printed mesh was folded diagonally and placed in a 1% calcium chloride solution for 3 minutes to fix the temporary shape; the hydrogel was transferred to a 10% sodium carbonate solution for 30 minutes to return to its original shape.

Embodiment 3

[0057] A method for preparing a shape memory hydrogel, comprising the following steps:

[0058] (2) Preparation of printing ink

[0059] With deionized water as solvent, add the modified hydrogel material (final concentration 0.13g / mL) of step (1), sodium alginate (final concentration 0.03g / mL) and photoinitiator (2,2-dimethoxy base-2-phenylacetophenone) (final concentration 0.4mg / mL), stir evenly, and put it in a 4°C refrigerator for defoaming.

[0060] Steps (1), (3), (4) are the same as in Example 1.

[0061] The printed mesh was folded diagonally and placed in a 1% calcium chloride solution for 3 minutes to fix the temporary shape; the hydrogel was transferred to a 10% sodium carbonate solution for 30 minutes to return to its original shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com