Vertical radial-flow adsorber

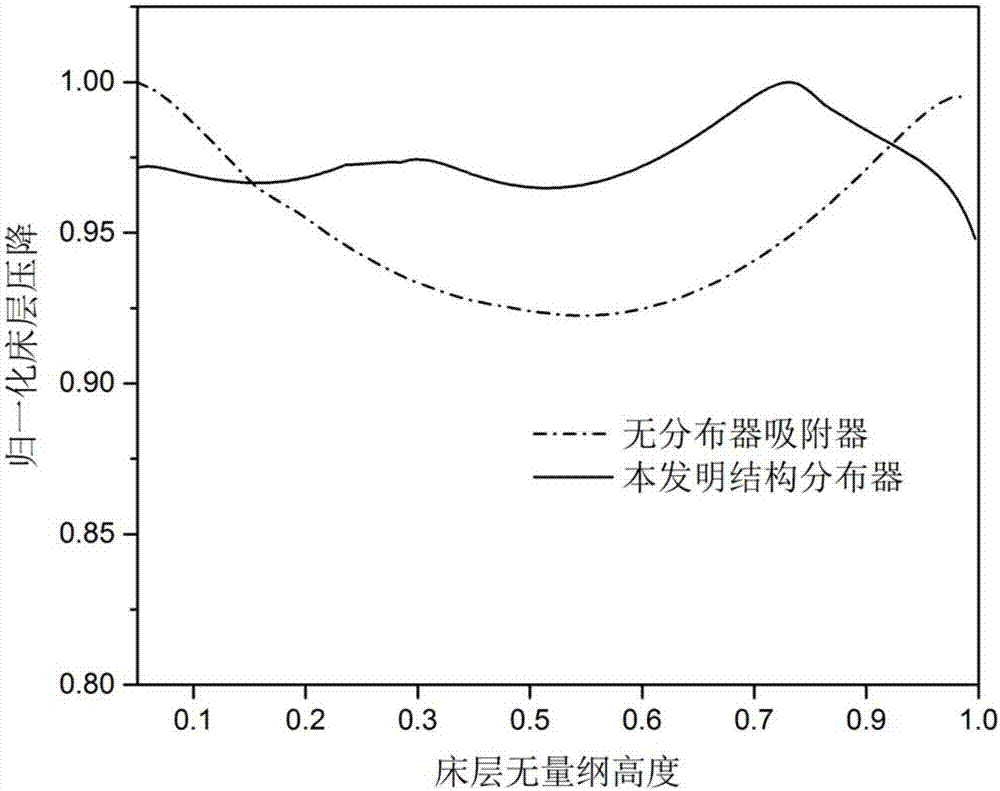

A radial flow, adsorber technology, applied in chemical instruments and methods, dispersed particle filtration, gas treatment, etc., can solve the problems of large processing flow, uneven flow steps, small footprint, etc. The effect of flow, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

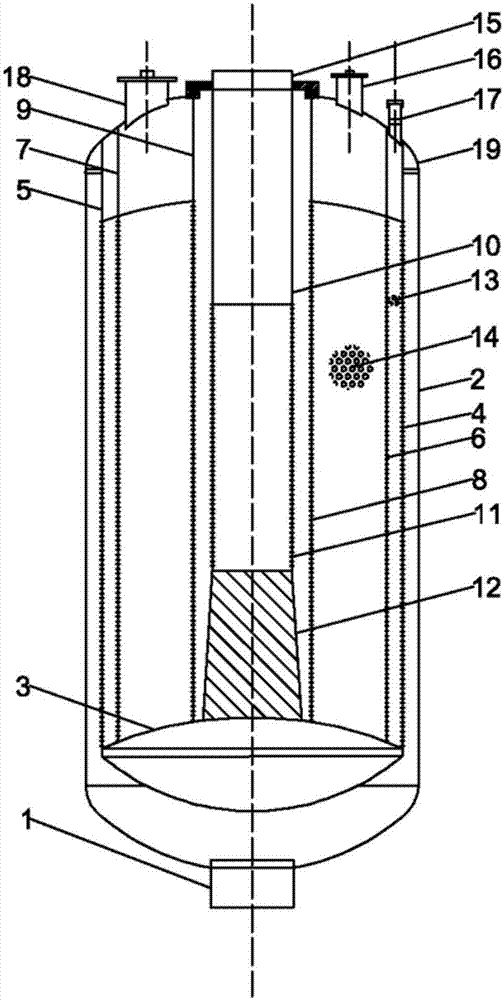

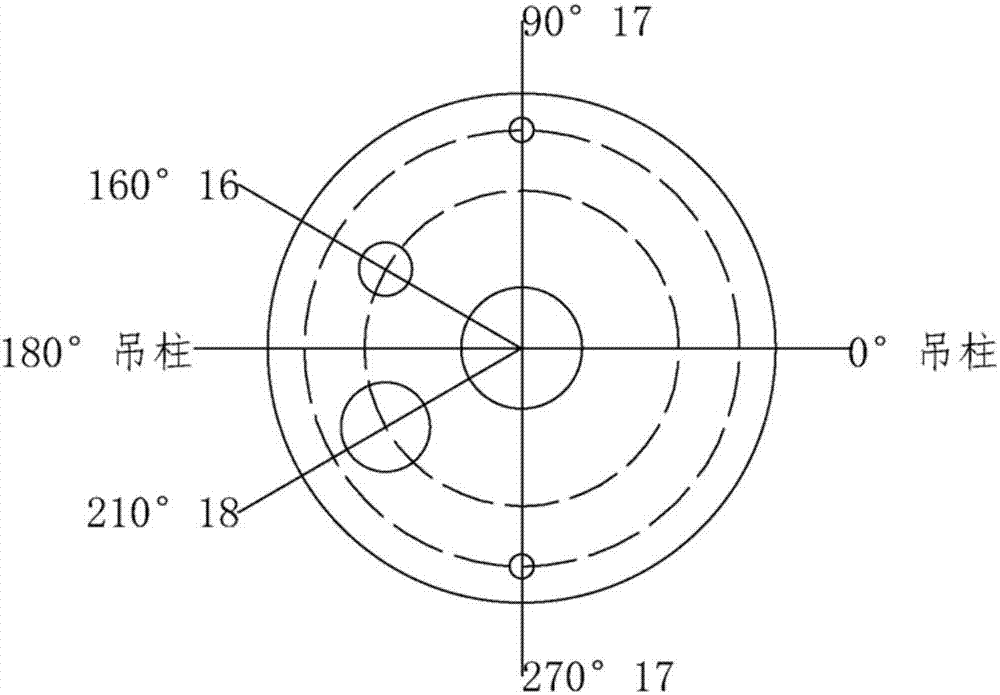

[0023] Such as figure 1 As shown, a vertical radial flow adsorber includes an inlet pipe 1, a tank body 2, a head 3, an outer cylindrical screen, a middle cylindrical screen, an inner cylindrical screen, and a central flow channel distribution Device, first adsorption bed 13, second adsorption bed 14, exhaust pipe 15, discharge port 16, two filling / discharge ports 17, manhole 18, load-bearing channel steel 19, the inlet pipe 1 is located in the tank body 2, the discharge port 16, filling / discharging port 17, manhole 18, load-bearing channel steel 19 and exhaust pipe 15 are all arranged on the upper end of the tank body 2, and the inner top of the tank body 2 hangs concentric circles Cylindrical screens are respectively the outer cylindrical screen, the middle cylindrical screen and the inner cylindrical screen, the lower end of the outer cylindrical screen, the lower end of the middle cylindrical screen and the inner cylindrical screen The lower ends of the screens are all fi...

Embodiment 2

[0025] A vertical radial flow adsorber, including an inlet pipe 1, a tank body 2, a head 3, an outer cylindrical screen, a middle cylindrical screen, an inner cylindrical screen, a central channel distributor, and a second An adsorption bed 13, a second adsorption bed 14, an exhaust pipe 15, a discharge port 16, two filling / discharge ports 17, a manhole 18, a load-bearing channel steel 19, and the air inlet pipe 1 is located at the lower end of the tank body 2 , the discharge port 16, filling / discharging port 17, manhole 18, load-bearing channel steel 19 and exhaust pipe 15 are all arranged on the upper end of the tank body 2, and a concentric cylindrical screen is suspended on the top of the tank body 2 The net is respectively the outer cylindrical screen, the middle cylindrical screen and the inner cylindrical screen, the lower end of the outer cylindrical screen, the lower end of the middle cylindrical screen and the lower end of the inner cylindrical screen are all fixed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com