Flotation method for zinc-copper sulphide ore

A copper-zinc sulfide roughing technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of index fluctuation, zinc loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

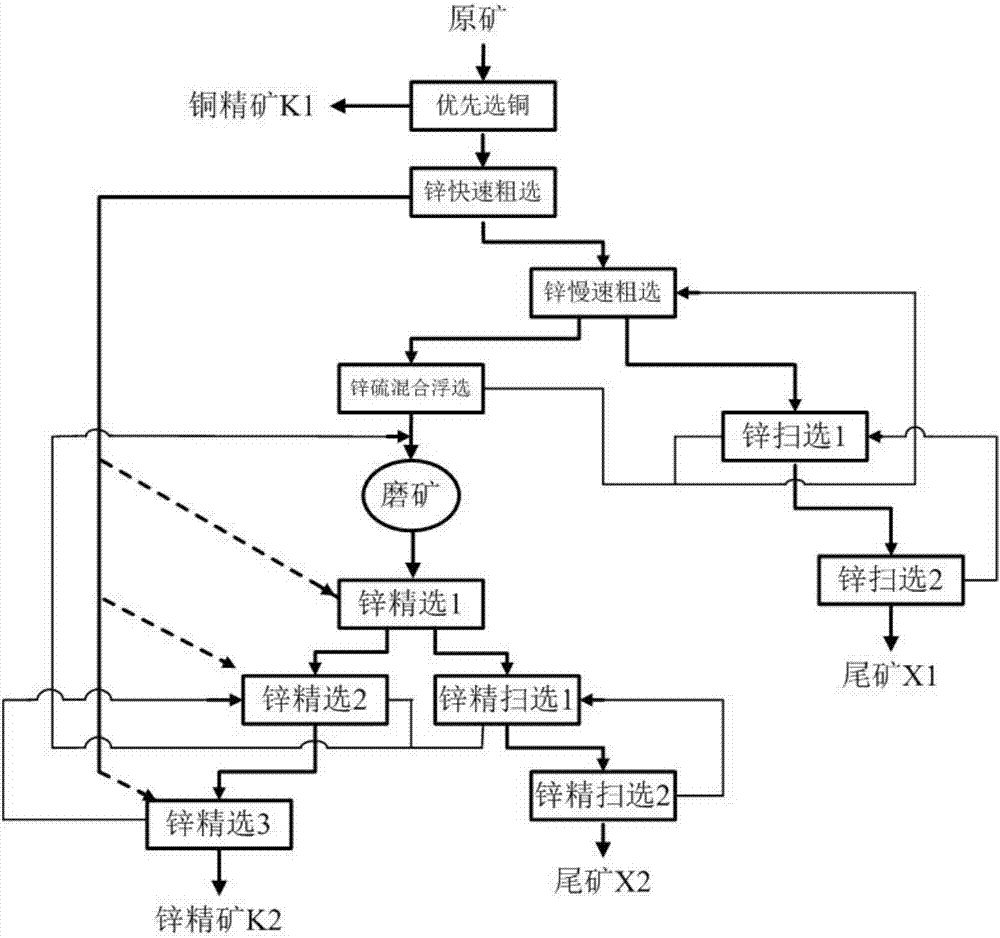

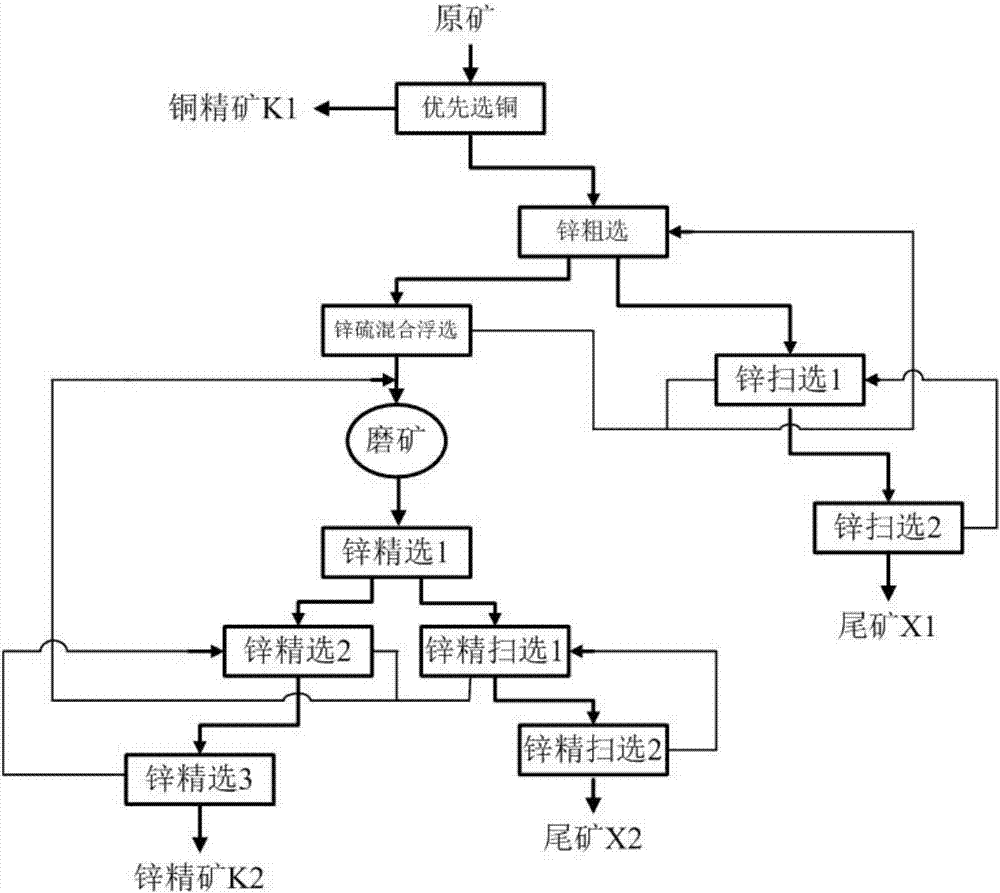

Method used

Image

Examples

Embodiment 1

[0028] 1) The 2.5%-4.5% zinc-containing copper-zinc sulfide ore is preferentially selected for copper, and copper tailings are left after copper selection;

[0029] 2) Add activator X-43, collector, and foaming agent 2# oil to the copper tailings described in step 1), and add activator X-43 according to the amount of 100g / t-500g / t per ton of raw ore t g, the amount of collector is 10g / t-30g / t, the amount of foaming agent 2# oil is 0g / t-30g / t, and the collector is composed of ethyl xanthate, 206 xanthate and butyl ammonium black The medicine is formulated according to the ratio of (5-12): (8-15): (1-5). In this embodiment, the consumption of activator X-43 is 100g / t, the consumption of collector is 10g / t, the consumption of foaming agent 2# oil is 2g / t, ethyl xanthate and 206 xanthate in collector Prepare with butylammonium black medicine in a ratio of 5:8:1. Then stir and adjust the thickness of the foam layer, and after obtaining a stable foam layer, perform rapid roughing ...

Embodiment 2

[0038] The raw ore is still zinc-containing 2.5%-4.5% copper-zinc sulfide ore, and with respect to embodiment 1, change process parameters and agent parameters and carry out process test, specifically as follows:

[0039] In step 2), the consumption of activator X-43 is 300g / t, and the consumption of collector is 20g / t, and foaming agent 2# oil consumption is 15g / t, and the ethyl xanthate in collector, 206 yellow Medicine and butyl ammonium black medicine are prepared in the ratio of 8:11:2;

[0040] In step 3), collector is 10g / t;

[0041] Step 5) according to per ton of raw ore lime consumption 500g / t;

[0042] In step 7), the selected lime consumption selected 1, selected 2, and selected 3 operating amounts are respectively 500g / t, 400g / t and 300g / t;

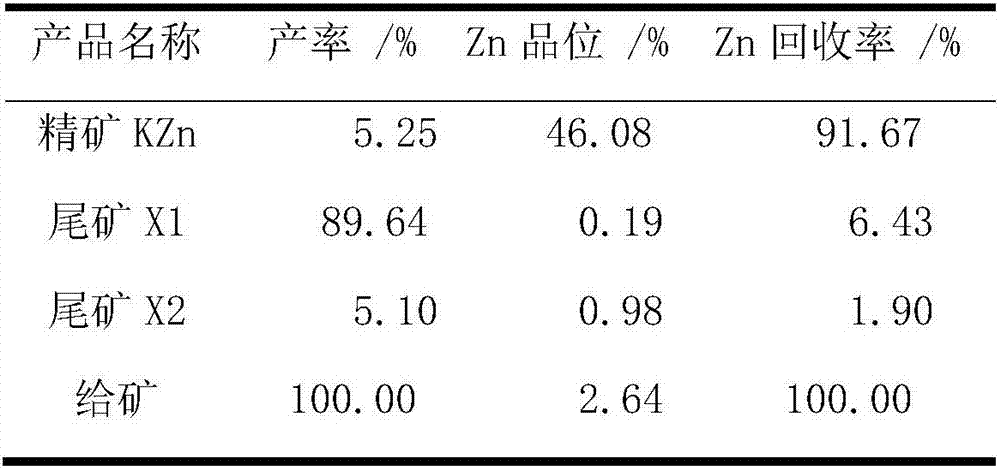

[0043] The test results of this embodiment show that the zinc concentrate grade of the process of the present invention is 46.08%, and the zinc recovery rate is 91.67%.

Embodiment 3

[0045] The raw ore is still zinc-containing 2.5%-4.5% copper-zinc sulfide ore, and with respect to embodiment 1, change process parameters and agent parameters and carry out process test, specifically as follows:

[0046] In step 2), the consumption of activator X-43 is 500g / t, and the consumption of collector is 30g / t, and foaming agent 2# oil consumption is 30g / t, and the ethyl xanthate in collector, 206 yellow Medicine and butyl ammonium black medicine are prepared in the ratio of 12:15:5;

[0047] In step 3), collector is 15g / t;

[0048] Step 5) according to per ton of raw ore lime consumption 600g / t;

[0049] In step 7), the amount of selected lime used in the selection 1, selection 2, and selection 3 operations are respectively 600g / t, 500g / t and 400g / t.

[0050] The test results of this embodiment show that the zinc concentrate grade of the process of the present invention is 45.78%, and the zinc recovery rate is 90.21%.

[0051] It can be seen from the above three e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com