TC4 titanium alloy selective laser melting additive manufacturing process

A laser selective melting and manufacturing process technology, applied in the field of metal additive manufacturing, can solve the problems of high internal stress of titanium alloy components, deformation of titanium alloy components, poor material shaping, etc., to improve yield strength and elongation, eliminate components The effect of deformation and high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

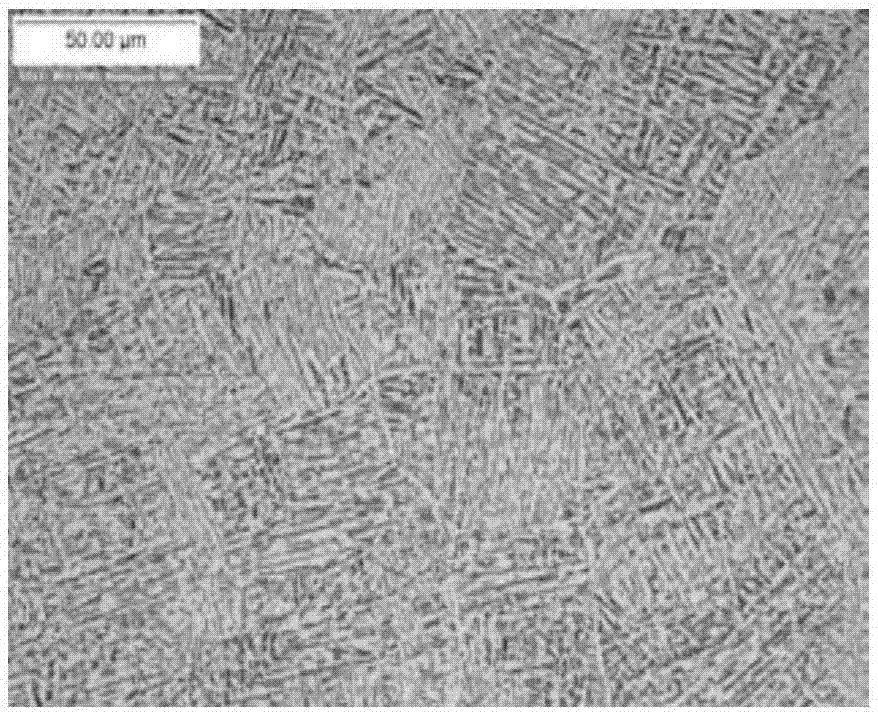

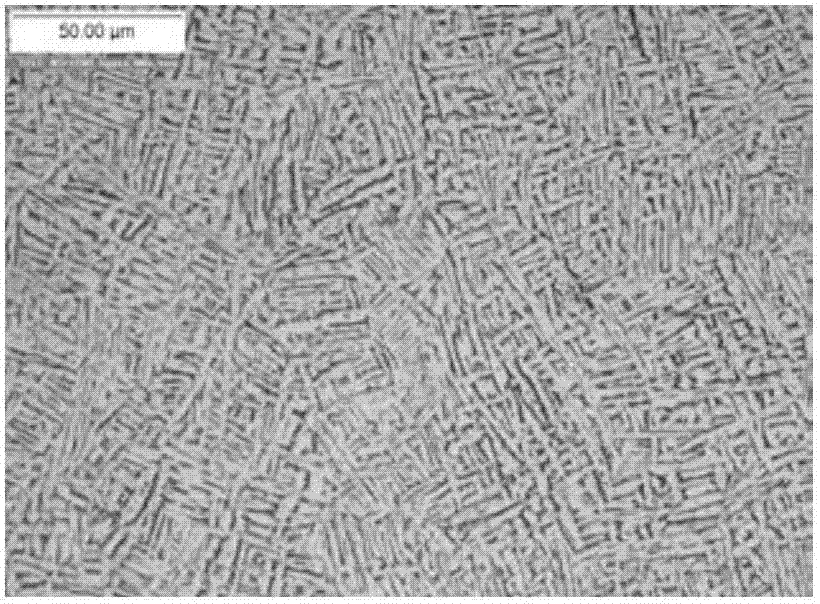

Image

Examples

preparation example Construction

[0035] In the present invention, by selecting the preparation method of the above-mentioned TC4 powder and combining a specific particle size, the mechanical properties of the prepared additive manufacturing component are better.

[0036] The TC4 titanium alloy laser selective melting additive manufacturing process of the present invention includes slicing and scanning processing of formed parts.

[0037] The present invention does not limit the specific instrument models and specifications used for the slicing and scanning, as well as the specific operation methods, as long as those skilled in the art are familiar with them.

[0038] The present invention slices the formed complex structural parts; the thickness of the slice is preferably 10-30 μm; more preferably 10-28 μm; most preferably 10-25 μm; most preferably 10-20 μm; planning component scanning path, using Jiugongge scanning mode, the deflection angle when scanning layer by layer, the deflection angle is between 36-40...

Embodiment 1

[0059] (1) The material is TC4 powder, the powder particle size range is 15-53 μm, among which d10 is controlled at 18 μm, d50 is controlled at 27 μm, and d90 is controlled at 42 μm;

[0060] (2) Slicing the formed parts with a slice thickness of 20 μm; planning the scanning path of the components, using the nine-square grid method to scan, and the deflection angle when scanning layer by layer, the deflection angle is 37°;

[0061] (3) Laser selective melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the forming chamber, and the replacement is repeated several times until the oxygen content of the forming chamber is lower than 500ppm and the pressure is maintained. Start printing at 30mbar;

[0062] (4) Firstly, the substrate is preheated through the preheating function, and the preheating temperature is 150°C. After the substrate is preheated, a layer of TC4 titanium alloy po...

Embodiment 2

[0069] (1) The material is TC4 powder, the powder particle size range is 15-53 μm, in which d10 is controlled at 15 μm, d50 is controlled at 30 μm, and d90 is controlled at 45 μm;

[0070] (2) Slicing the formed parts with a slice thickness of 10 μm; planning the scanning path of the components, using the nine-square grid method to scan, and the deflection angle when scanning layer by layer, the deflection angle is 38°;

[0071] (3) Laser selective melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the forming chamber, and the replacement is repeated several times until the oxygen content of the forming chamber is lower than 500ppm and the pressure is maintained. Start printing at 30mbar;

[0072] (4) Firstly, the substrate is preheated through the preheating function, and the preheating temperature is 100°C. After the substrate is preheated, a layer of TC4 titanium alloy powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com