Method for efficiently dispersing graphene into polymer

A polymer and graphene technology, applied in the field of nanocomposite material preparation, achieves the effects of less pollution, simple preparation process and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

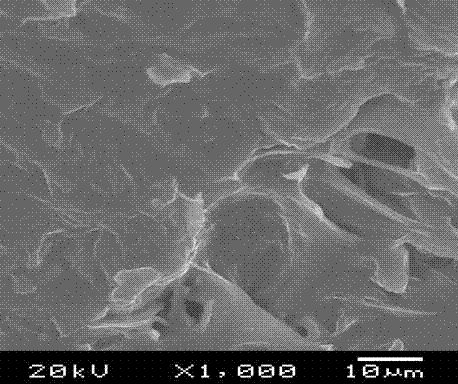

Image

Examples

Embodiment 1

[0028] (1) Mix graphene and SBS polymer at a mass ratio of 1:2, add it to the mixer, and control the working temperature to 120 ° C. During the rotation process, the graphene is dispersed in the polymer, and the graphene is in the polymer. It is continuously compressed and sheared, and by mixing, a homogeneous graphene mixture is formed;

[0029] (2) adding cross-linking agent hydrogen peroxide to the homogeneous graphene mixture obtained in step (1), the quality of the cross-linking agent is 1% of the polymer, and the mixing is uniform in the internal mixer, and then the mixing is carried out. Press the sheet by machine, and further stretch it into a sheet on a biaxial stretching machine. The thickness of the sheet is 0.005mm. By stretching the elastic polymer, the graphene is further subjected to the stretching force until the sheet is split, and the overlapping part of the graphene is stretched and dispersed. open, then knead;

[0030] (3) The graphene-dispersed polymer pe...

Embodiment 2

[0033] (1) Mix graphene and polymer PS at a mass ratio of 1:3, add it to the mixer, and control the working temperature to be 170 ° C. During the rotation process, the graphene is dispersed in the polymer, and the graphene is in the polymer. It is continuously compressed and sheared, and by mixing, a homogeneous graphene mixture is formed;

[0034] (2) adding the cross-linking agent cumene to the homogeneous graphene mixture obtained in step (1), the quality of the cross-linking agent is 3% of the polymer, and the mixing is uniform in the internal mixer, and then the Machine press, and further stretch it into a thin sheet on a biaxial stretching machine, keeping the polymer at an ambient temperature of 100-150 ° C, it is necessary to ensure that the polymer does not break, and the thickness of the sheet after stretching is 0.01 mm; The stretch elastic polymer makes the graphene further bear the stretching force, and the overlapping part of the graphene is stretched and dispers...

Embodiment 3

[0037] (1) Mix graphene and polymer EVA at a mass ratio of 1:5, add to the mixer, and control the working temperature to 80 ° C. During the rotation process, the graphene is dispersed in the polymer, and the graphene is in the polymer. It is continuously compressed and sheared, and by mixing, a homogeneous graphene mixture is formed;

[0038] (2) adding a cross-linking agent aldehyde to the homogeneous graphene mixture obtained in step (1), the quality of the cross-linking agent is 5% of the polymer, and it is uniformly mixed in an internal mixer, and then the mixer is pressed. The sheet is further stretched into a sheet on a biaxial stretching machine. After the stretching is completed, the thickness of the sheet is 0.005 mm; by stretching the elastic polymer, the graphene is further subjected to the stretching force, and the overlapping part of the graphene is stretched and dispersed. , and then knead;

[0039] (3) Graphene-dispersed polymer pellets are obtained by repeatedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com