Method for preparing mesoporous carbon

A mesoporous carbon and solution technology, applied in the field of adsorption, can solve the problems of environmental protection and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of ZIF-8

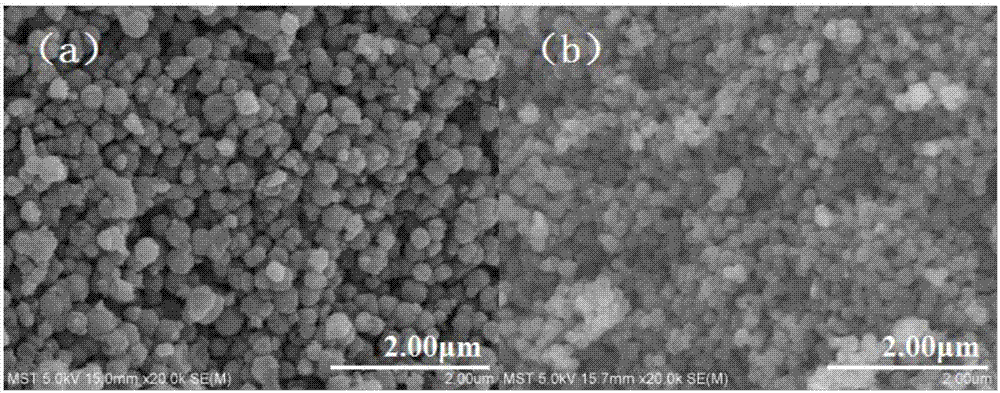

[0028] Firstly, 50 mL of 0.64 mol / L methanol solution of 2-methylimidazole and 50 mL of 0.16 mol / L methanol solution of zinc nitrate hexahydrate were prepared. Put the prepared 2-methylimidazole methanol solution into a beaker, add zinc nitrate hexahydrate methanol solution under stirring state, continue to stir for 10 min and then let it stand for reaction for 4 h; after standing, the product is centrifuged and washed with absolute ethanol for 3 times, and finally put the final sample in the oven for 60 o Bake at C for 24 h.

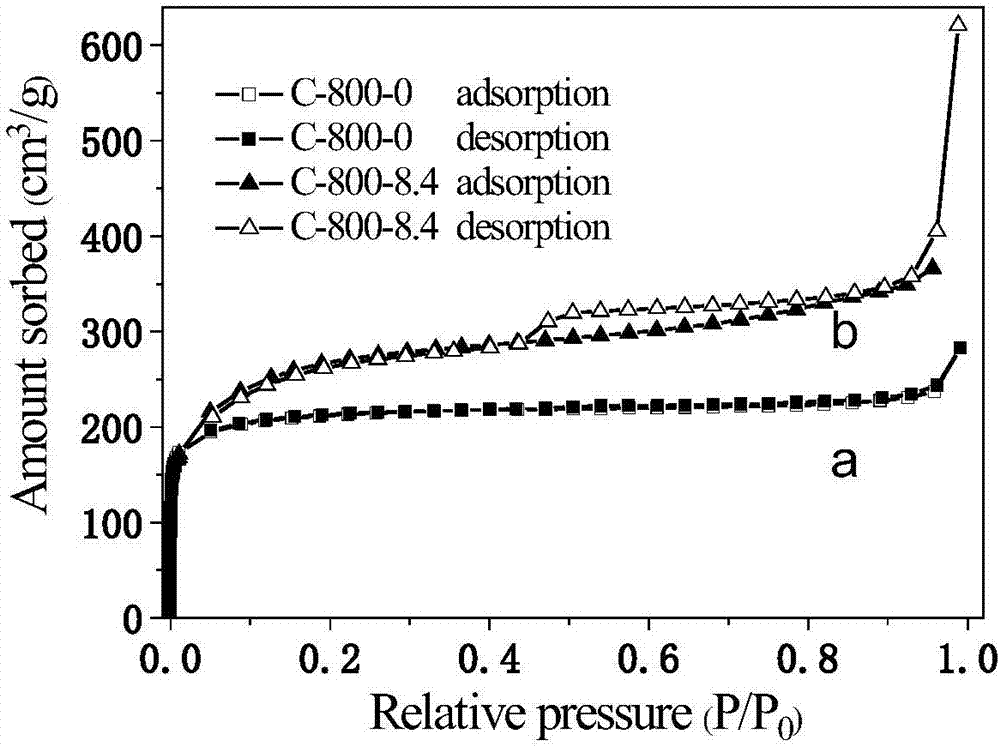

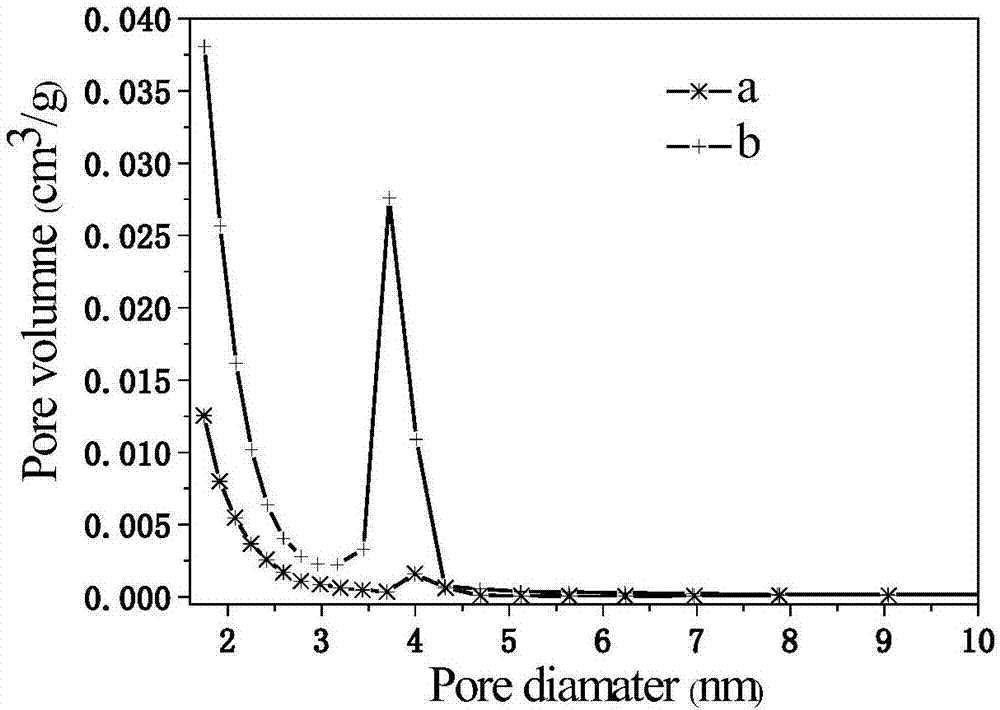

[0029] (2) Preparation of mesoporous carbon

[0030] Weigh 2 g of dry ZIF-8 in a tube furnace, use a vacuum pump to extract part of the air in the tube, then fill the tube with nitrogen, control the initial oxygen concentration in the tube to 8.4%, then turn on the instrument to heat up, nitrogen, Maintain a flow rate of 60 mL / min, raise the temperature to 800 °C at a rate of 5 °C / min and maintain it for 5 h, then co...

Embodiment 2

[0038] (1) Preparation of ZIF-8

[0039] Firstly, 50 mL of 0.64 mol / L methanol solution of 2-methylimidazole and 50 mL of 0.16 mol / L methanol solution of zinc nitrate hexahydrate were prepared. Put the prepared 2-methylimidazole methanol solution into a beaker, add zinc nitrate hexahydrate methanol solution under stirring, continue stirring for 30 min, and then let it stand for 6 h; after standing, the product was centrifuged and washed with absolute ethanol for 3 times, and finally the final sample was placed in an oven for 90 o Bake at C for 12 h.

[0040] (2) Preparation of mesoporous carbon

[0041]Weigh 2 g of dry ZIF-8 in a tube furnace, use a vacuum pump to extract part of the air in the tube, then fill the tube with nitrogen, control the initial oxygen concentration in the tube to 6.3%, then turn on the instrument to heat up, and nitrogen, Maintain a flow rate of 70 mL / min, raise the temperature to 600 °C at a rate of 2 °C / min and maintain it for 2 hours, then cool ...

Embodiment 3

[0045] (1) Preparation of ZIF-8

[0046] Firstly, 50 mL of 0.64 mol / L methanol solution of 2-methylimidazole and 50 mL of 0.16 mol / L methanol solution of zinc nitrate hexahydrate were prepared. Put the prepared 2-methylimidazole methanol solution into a beaker, add zinc nitrate hexahydrate methanol solution under stirring, continue to stir for 20 min, and then let it stand for 2 h; after standing, the product was centrifuged and washed with absolute ethanol for 3 times, and finally put the final sample in the oven for 60 o Bake at C for 24 h.

[0047] (2) Preparation of mesoporous carbon

[0048] Weigh 2 g of dry ZIF-8 in a tube furnace, use a vacuum pump to extract part of the air in the tube, then fill the tube with helium, control the initial oxygen concentration in the tube to 16.8%, then turn on the instrument to heat up, and pass helium Keep the flow rate at 60 mL / min, raise the temperature to 1000 °C at a rate of 10 °C / min and maintain it for 10 h, then cool naturall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com