Extraction method of sterol and sterol

An extraction method and sterol technology, which are applied to the sterol extraction method and the sterol field, can solve the problems of low yield, high cost, complicated purification process and the like, and achieve the effects of high product purity, low production cost and high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

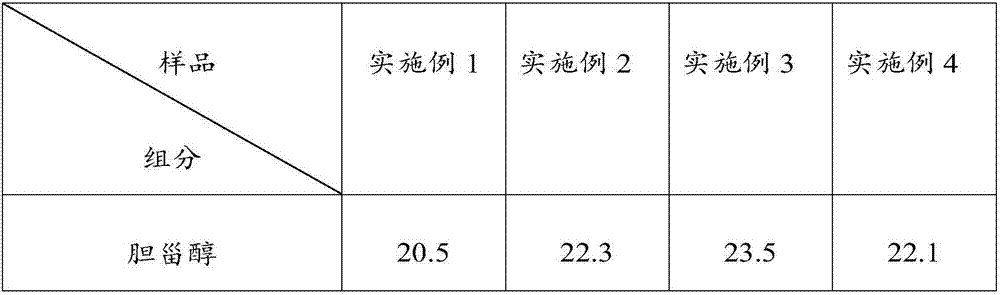

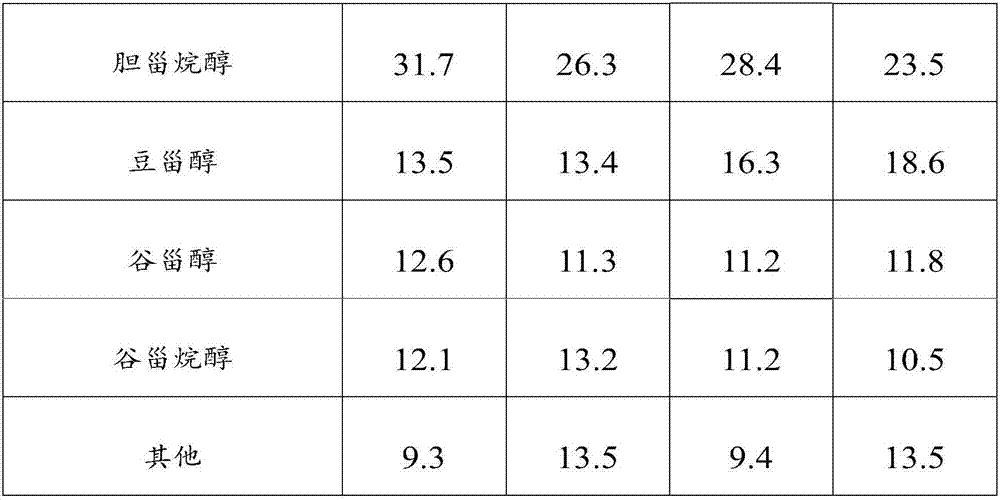

Examples

Embodiment 1

[0043] The present embodiment provides a kind of extraction method of sterol, it comprises the following steps:

[0044]First, after mixing 50 mL of seabuckthorn seed oil with 400 mL of potassium hydroxide solution with a concentration of 0.5 mol / L, the saponification reaction was carried out at a temperature of 75° C. for 230 min to obtain a saponified liquid.

[0045] Next, take 400 mL of the above saponified solution, add water to dilute to 1000 mL, extract with 400 mL of petroleum ether, filter to obtain the extract, and evaporate the extract to dryness at a temperature of 27°C.

[0046] This embodiment also provides a sterol, which is prepared by the above-mentioned method.

Embodiment 2

[0048] The present embodiment provides a kind of extraction method of sterol, it comprises the following steps:

[0049] First, after mixing 50 mL of seabuckthorn seed oil with 400 mL of potassium hydroxide solution with a concentration of 0.5 mol / L, the saponification reaction was carried out at a temperature of 75° C. for 230 min to obtain a saponified liquid.

[0050] Next, take 400mL of the above saponification solution, add water to dilute to 1000mL, extract with 400mL of petroleum ether, filter to obtain the extract, evaporate the extract at a temperature of 27°C, and dry the evaporated residue to obtain a paste Initial product.

[0051] Finally, mix the paste primary product with water, heat and dissolve, then crystallize naturally, and collect it by filtration while cold.

[0052] This embodiment also provides a sterol, which is prepared by the above-mentioned method.

Embodiment 3

[0054] The present embodiment provides a kind of extraction method of sterol, it comprises the following steps:

[0055] First, after mixing 50mL seabuckthorn fruit oil with 350mL potassium hydroxide ethanol solution with a concentration of 0.4mol / L, saponification reaction was carried out at 81°C for 200min, and the saponified product was evaporated to remove ethanol at 35°C to obtain Saponification solution.

[0056] Next, take 400mL of the above saponified solution, add water to dilute to 1000mL, then extract 3 times with 400mL of petroleum ether, filter and mix the extracted products to obtain an extract, evaporate the extract at a temperature of 35°C, and evaporate the remaining The product was concentrated and then dried to obtain a paste-like primary product.

[0057] Finally, wash the paste-like primary product twice with 0.45mol / L potassium hydroxide, and then wash three times with distilled water, then heat and dissolve the solid in water, crystallize naturally, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com