Remotely coated fluorescent powder plate and preparation method thereof

A phosphor and yellow phosphor technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as affecting the excitation efficiency of phosphors, weakening the luminous efficiency, reducing the photoelectric index of the light source, and achieving high hardness and good shape retention. , the effect of good photoelectric index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Design a 25W integrated lamp, as follows:

[0034] The LED light source adopts blue light chip, the single optical power is between 440-480mw (350mA), it adopts the form of 5 parallel 15 strings, the total input voltage is 45V, and the total input current is 0.55A, so the power of the whole LED module is 24.75W .

[0035] 1. The preparation of the phosphor sheet comprises the following steps:

[0036] (1) Mold design and production: According to the structure of the dispenser, design and manufacture a glass mold with grooves and positioning through holes that matches the dispenser;

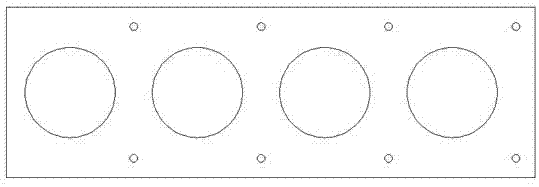

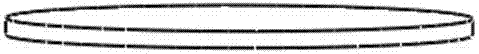

[0037] Such as figure 1 Shown is the schematic diagram of the glass mold made. The length of the glass mold is 150cm, the width is 80cm, and the thickness is 2cm; there are four grooves and eight positioning through holes on the glass mold; wherein, the diameter of the groove is 60mm, and the depth is 2mm, and the diameter of the positioning through hole is 2.5mm;

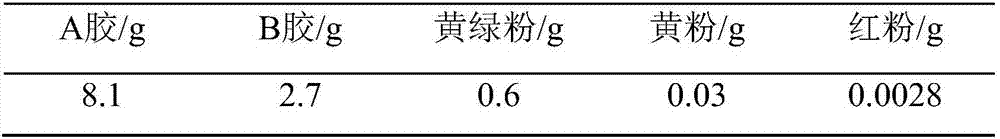

[0038] (2) Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com