Thermoplastic elastomer composition for battery pack protective member

A technology for thermoplastic elastomers and protective components, which is applied to battery pack components, large-size batteries/battery packs, small-size batteries/battery packs, etc., to achieve excellent flexibility and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

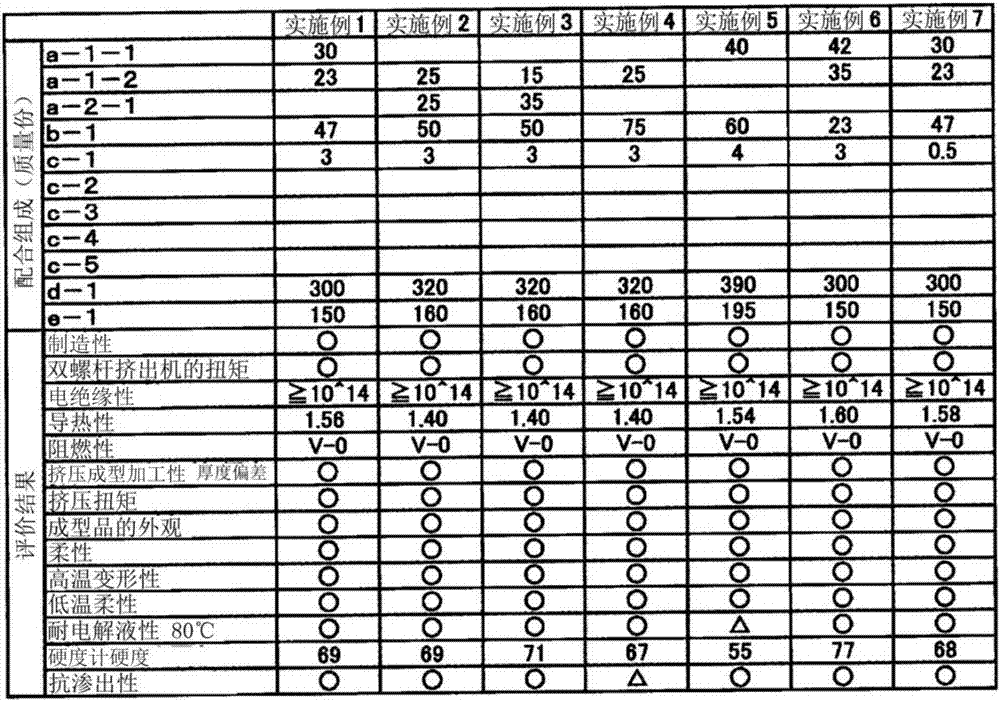

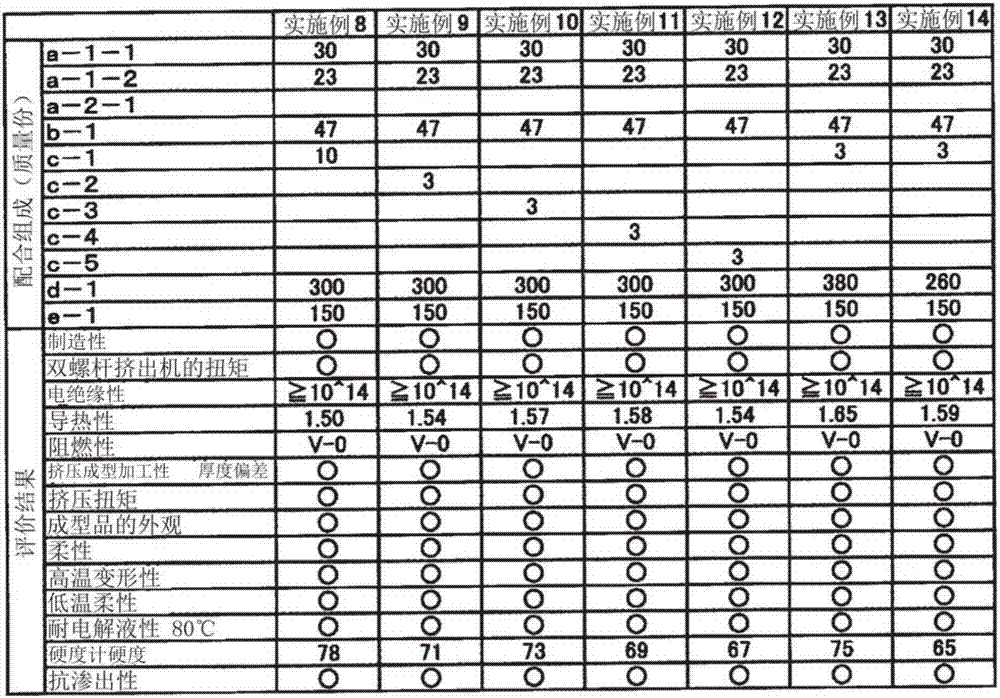

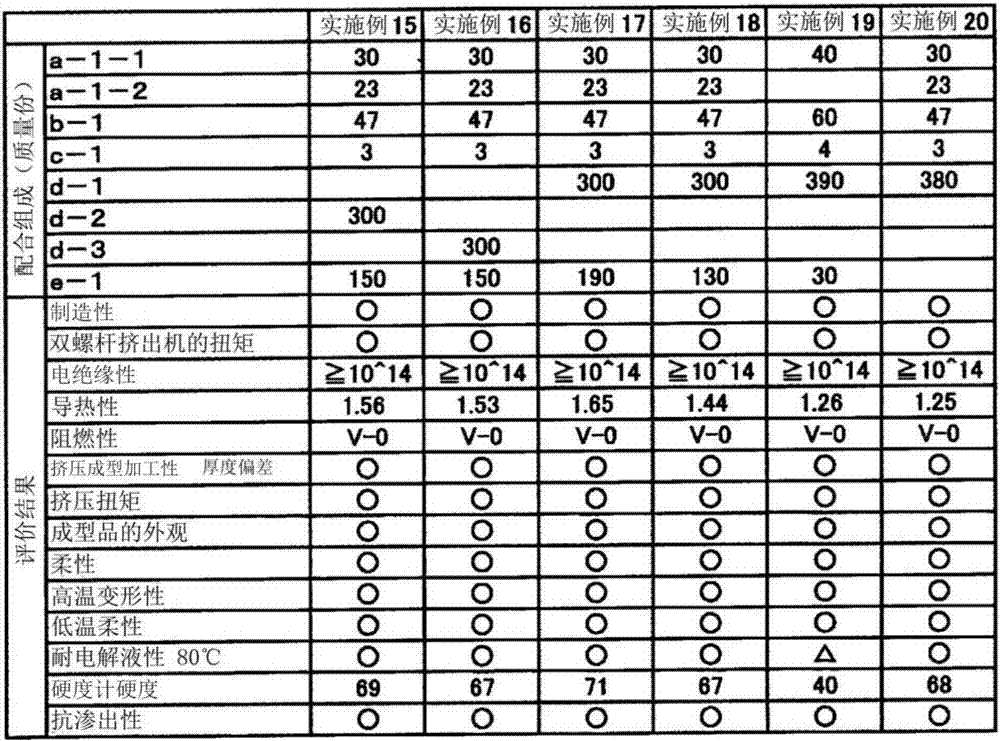

Embodiment 1~32、 comparative example 1~12

[0104]Using a 20-L capacity pressurized kneader, melt-kneading was carried out at a discharge temperature of 175° C. for the compounds having the compounding ratios shown in any one of Tables 1 to 7. Under the condition that the set temperature of the mold is 210° C., the obtained composition is thermally cut to obtain pellets. Next, using the obtained pellets, using a heating and pressing machine, hot pressing was carried out at a temperature of 220° C., a preheating time of 3 minutes, and a pressurization time of 3 minutes. Under cold pressing, a 1mm thick tablet is obtained. And obtain 2mm, 3mm, 6mm thick compressed tablets respectively according to the same method. The manufacturability of the above process was evaluated according to the following criteria. Furthermore, the following tests (3) to (8) were performed. The results are shown in any one of Tables 1-7.

[0105] (1) Manufacturability

[0106] ◯: There is no particular problem, and each tablet having a good t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com