Method for synthesizing microbial oils by two-stage fed-batch fermentation

A microbial oil and feeding technology, applied in the direction of fermentation, can solve the problems of inability to complete the high-density fermentation of volatile fatty acids, loss of industrial production prospects, and unsatisfactory yields, so as to overcome inhibition, improve yield, and increase consumption. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

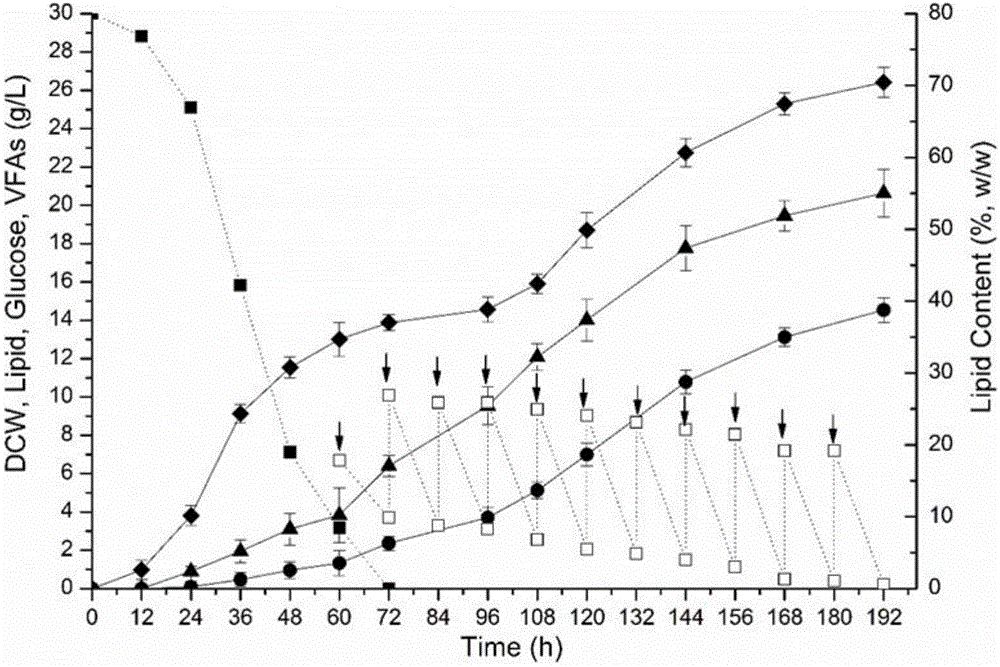

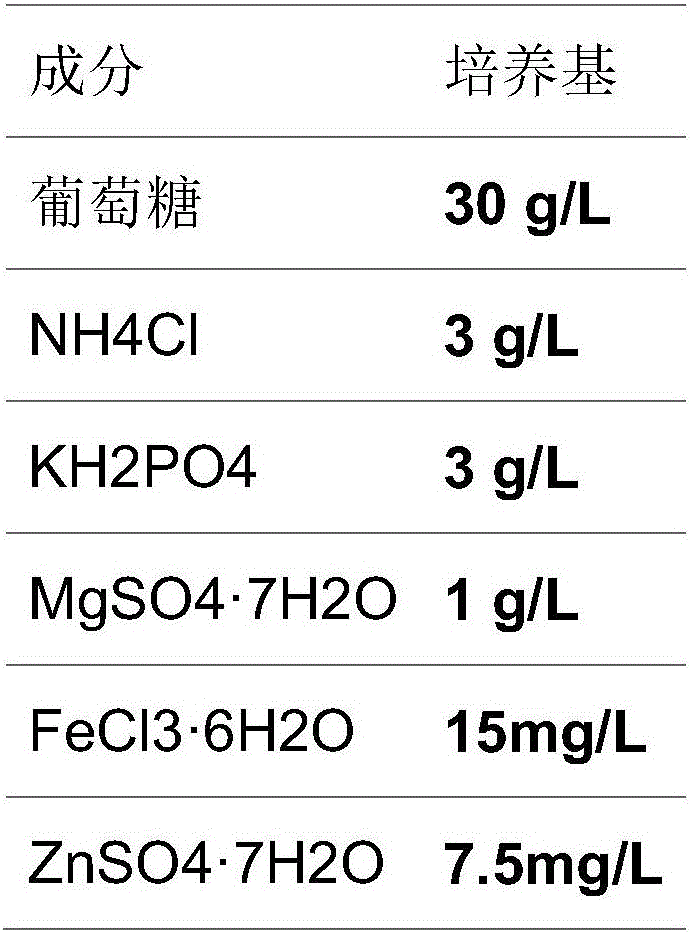

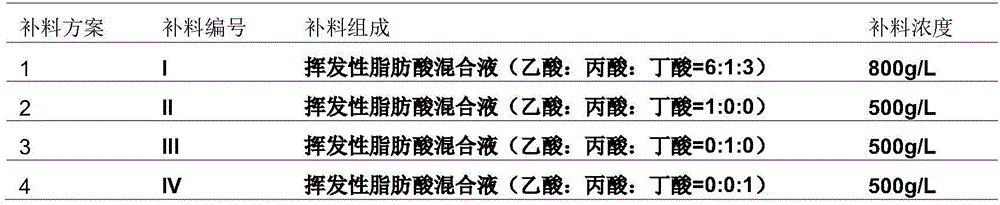

[0021] Implement with feeding scheme 1 in the two-stage fed-batch fermentation scheme described in table 2, concrete process is as follows:

[0022] (1) The first stage: Prepare 0.9L basic fermentation medium (see Table 1 for its composition), insert 100mL of Cryptococcus albicans seed solution (the sugar concentration in the liquid seed fermentation medium is not higher than 2g / L, other components The same concentration as that of the basic fermentation medium, see Table 1, the seed liquid of Cryptococcus albicans is prepared according to conventional techniques) in a 2.5L fermenter, start fermentation at 25°C and an initial stirring speed of 200 rpm, and then Introduce sterile air at a flow rate of 1.0vvm, and try to keep the dissolved oxygen concentration not lower than 20%; use 50% ammonia water to adjust the pH to 6.0, ammonia water can be used as a nitrogen source at the same time, and monitor the pH, dissolved oxygen value and Changes in carbon source consumption.

[0...

Embodiment 2

[0025] Implement with feeding scheme 2 in the two-step fed-batch fermentation scheme described in table 2, that is, the second stage feed feeding II, and the fermentation process is the same as example 1.

Embodiment 3

[0027] Implement with feeding scheme 2 in the two-step fed-batch fermentation scheme described in Table 2, that is, the second stage feed feeding III, and other processes of fermentation and cultivation are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com