Pouch case for secondary battery and pouch type secondary battery comprising same

A secondary battery, pouch type technology, applied in the direction of secondary batteries, lithium batteries, battery pack components, etc., can solve the problems of reducing the service life of secondary batteries, accelerating battery deterioration and gas generation, reducing volume, etc. The effect of reliability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

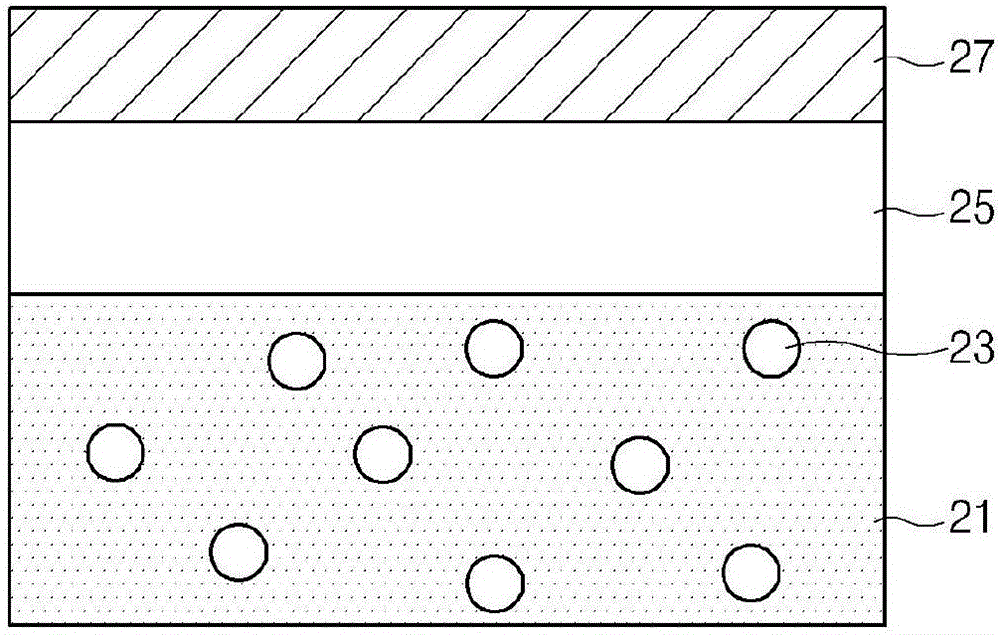

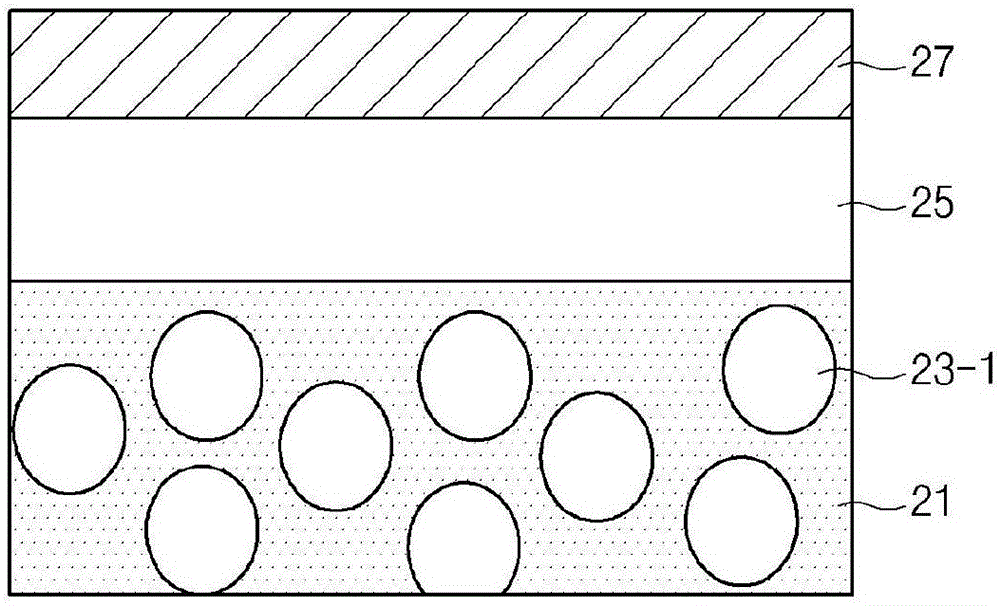

[0089] (Preparation of inner resin layer)

[0090] The thermosetting hygroscopic agent carboxymethylcellulose was ground for 20 minutes using a shear breaking device rotating at 3000 rpm to prepare carboxymethylcellulose powder (average particle diameter: 1 μm).

[0091] Subsequently, carboxymethylcellulose powder (3% by weight) was dispersed in a polypropylene resin solution, and the resultant was extruded at about 220° C. to prepare an inner resin layer having a thickness of 40 μm.

[0092] (Preparation of pouch shell tablets)

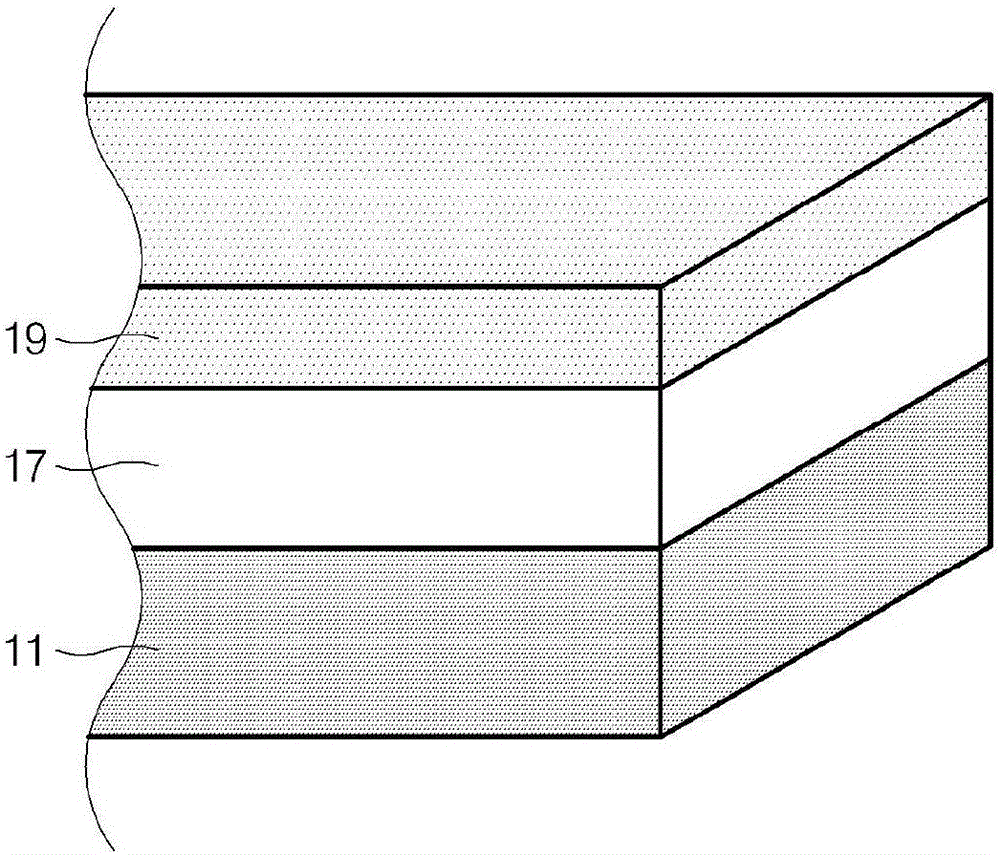

[0093] A norbornene resin having a thickness of 60 μm was laminated on the inner resin layer to prepare an intermediate resin layer.

[0094] Next, an outer resin layer composed of 15 μm-thick nylon was laminated on the intermediate resin layer to manufacture a pouch-type case for a secondary battery.

Embodiment 2

[0096] (Preparation of inner resin layer)

[0097] The acrylic acid-acrylamide copolymer was ground by rotating at 3000 rpm for 20 minutes using a shear fracture apparatus to prepare an acrylic acid-acrylamide copolymer powder (average particle diameter: 1 μm).

[0098] Subsequently, acrylic acid-acrylamide copolymer powder (5% by weight) was dispersed in a polypropylene resin solution, and the resultant was extruded at about 220° C., thereby preparing an inner resin layer having a thickness of 40 μm.

[0099] (Preparation of pouch shell tablets)

[0100] A norbornene resin having a thickness of 60 μm was laminated on the inner resin layer to form an intermediate resin layer.

[0101] Next, an outer resin layer composed of 15 μm-thick nylon was laminated on the intermediate resin layer to manufacture a pouch-type case for a secondary battery.

Embodiment 3

[0103] The ethylene-maleic anhydride copolymer was ground by rotating at 3000 rpm for 20 minutes using a shear fracture apparatus to prepare ethylene-maleic anhydride copolymer powder (average particle diameter: 1 μm).

[0104] Subsequently, ethylene-maleic anhydride copolymer powder (1% by weight) was dispersed in a polypropylene and acrylic acid copolymer resin solution, and the resultant was extruded and released at about 220° C., thereby preparing an interior having a thickness of 40 μm. resin layer.

[0105] (Preparation of pouch shell tablets)

[0106] A norbornene resin having a thickness of 60 μm was laminated on the inner resin layer to prepare an intermediate resin layer.

[0107] Next, an outer resin layer formed of 15 μm-thick nylon was laminated on the intermediate resin layer to manufacture a pouch-type case for a secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com