A kind of preparation method of bletilla striata electric mosquito sheet

A production method, electric mosquito technology, applied in chemical instruments and methods, botanical equipment and methods, and resistance to vector-borne diseases, etc., can solve the problems of unfavorable heating of electric mosquito sheets, difficulty in quickly volatilizing mosquito killing substances, and long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

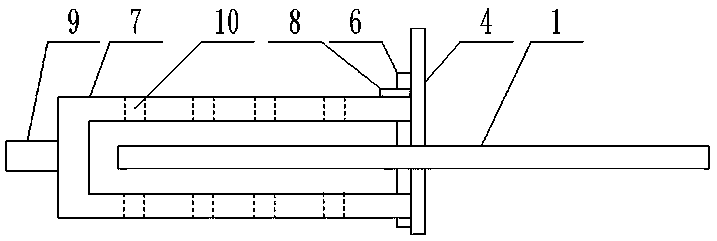

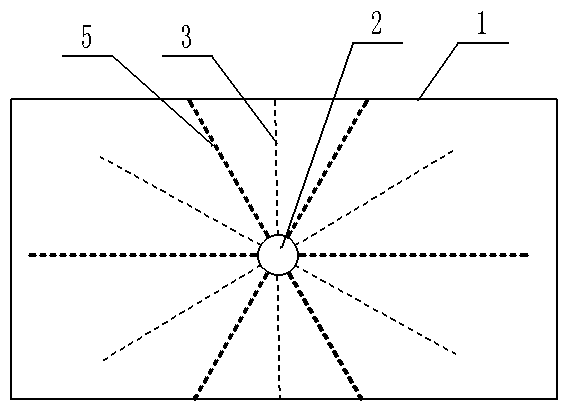

[0020] The reference signs in the accompanying drawings include: electric mosquito sheet 1, through hole 2, cotton thread 3, cotton mandrel 4, aluminum foil thread 5, metal rod 6, U-shaped plate 7, magnetic block 8, insulating handle 9, air hole 10 .

[0021] A kind of preparation method of bletilla striata electric mosquito sheet, refer to figure 1 and figure 2 ,include:

[0022] 1. Forming, mainly including the following specific operations:

[0023] A. Layer processing, take three layers of paper sheets for making electric mosquito sheet 1, stack them layer by layer, stack absorbent cotton between adjacent layers of paper sheets to make a primary sheet, and punch through the hole 2 in the center of the primary sheet ;

[0024] B, thread embedding, take the cotton mandrel 4, divide the upper end of the cotton mandrel 4 into six strands of cotton thread 3, pass the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com