Processing method for fresh ginger

A ginger and steaming technology, which is applied in the field of processing Chinese herbal medicines, can solve the problems of changes in the dissolution of beneficial ingredients, different content and types of beneficial ingredients, and achieve the effects of promoting dissolution, protecting fineness, and excellent color and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

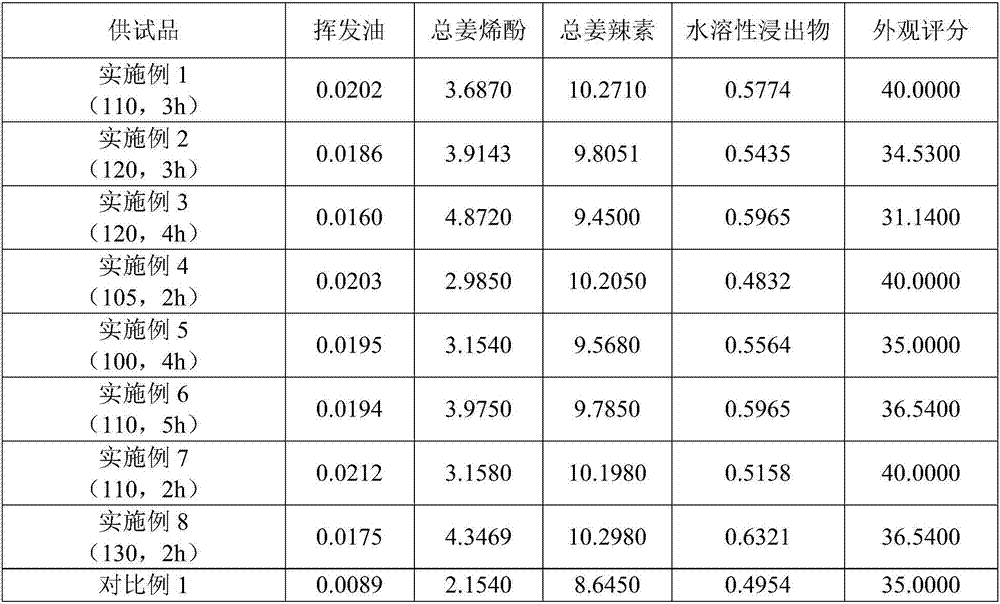

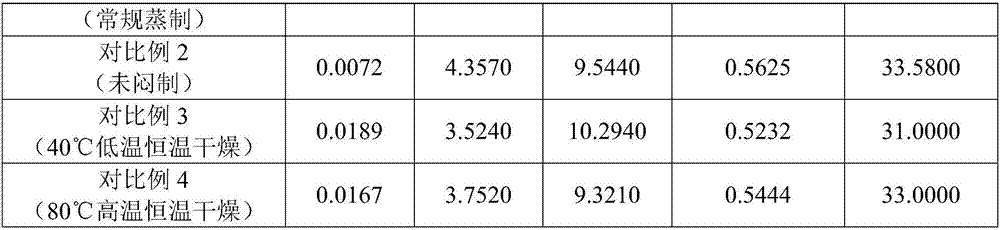

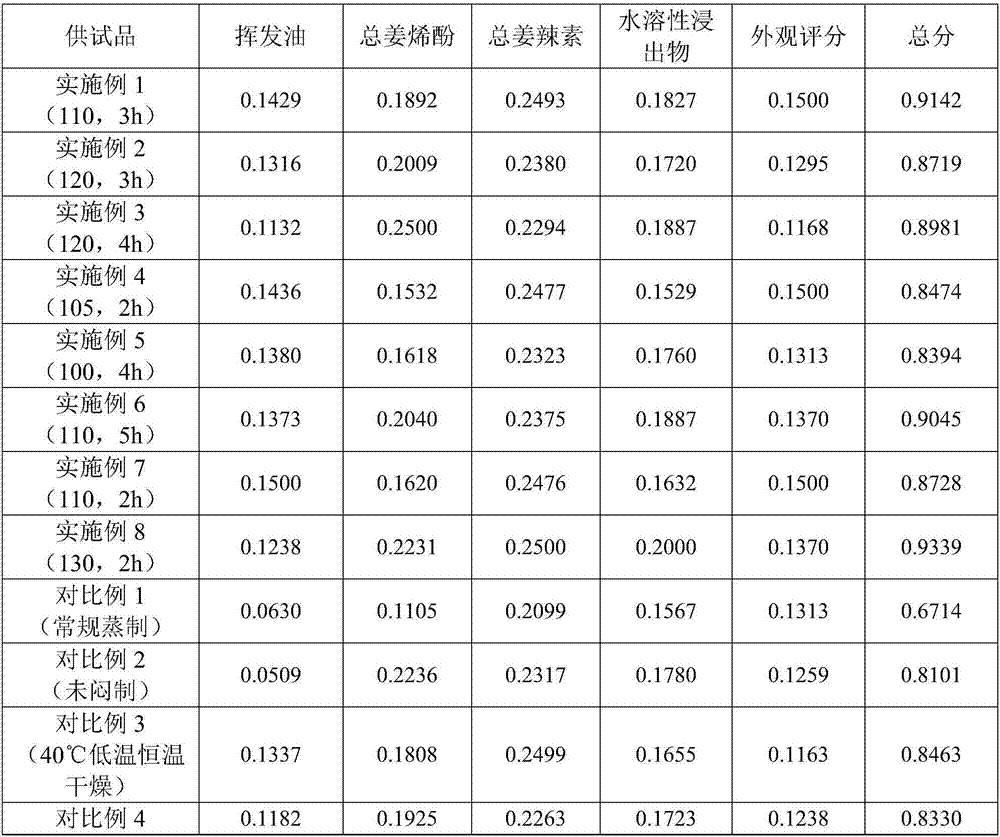

Examples

Embodiment 1

[0021] (1) Net system: get 6-gingerol, 8-gingerol and 10-gingerol total content to be 1mg / g, wherein 6-gingerol content is the fresh ginger within 20 days after harvesting of 0.5mg / g is ginger Raw materials, wash away the sediment and remove impurities;

[0022] (2) Exhaust the air: transfer the cleaned ginger in step (1) into the steamer, rapidly raise the temperature to around 100°C, and open the exhaust valve of the steamer after 2 minutes to discharge the air and water vapor;

[0023] (3) Airtight steaming: in airtight step (2) in the steamer after exhausting the air, steam the ginger at 110° C. for 3 hours;

[0024] (4) Stuffing: After the airtight steaming is completed, keep the airtight stuffing, after cooling it, open the steamer;

[0025] (5) Drying: spread the stuffed ginger 5-10cm thick, dry the moisture to 50% at 50°C, gradually increase the temperature to 70°C, control the moisture between 6%-13%, and obtain processed ginger products .

Embodiment 2

[0027] The difference between embodiment 2 and embodiment 1 is only in step (3):

[0028] (3) Airtight steaming: in airtight step (2) steam the ginger in an airtight steamer at 120° C. for 3 hours.

Embodiment 3

[0030] The difference between embodiment 3 and embodiment 1 is only in step (3):

[0031] (3) Airtight steaming: in airtight step (2) steam the ginger in an airtight steamer at 120° C. for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com