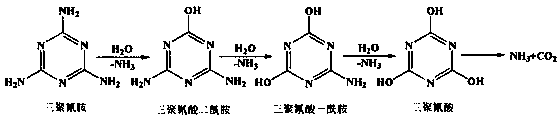

A method for heterogeneous catalytic hydrolysis of melamine, cyanuric acid or melamine oat waste residue

A heterogeneous catalysis, melamine technology, applied in the field of solid waste treatment and circular economy, can solve the problems of low effective components of products, complex process, large consumption of acid and alkali, etc., achieve green environmental protection recovery and utilization, reduce reaction temperature, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The initial concentration of melamine is 0.67g / L, the mass ratio of activated alumina is 3.8%, the reaction temperature is 220°C, and the reaction time is 5 hours. After the reaction, the solution is detected, and the degradation rate of melamine is 99.8%. Ammonia and carbon dioxide The yield was 96.1%.

Embodiment 2

[0014] The initial concentration of melamine is 2.4g / L, the mass ratio of adding pseudo-boehmite is 4.6%, the reaction temperature is 200°C, and the reaction time is 7 hours. After the reaction, the solution is detected. The degradation rate of melamine is 93.2%. And the yield of carbon dioxide is 91.7%.

Embodiment 3

[0016] The initial concentration of cyanuric acid is 0.67g / L, the mass ratio of adding activated alumina is 3.8%, the reaction temperature is 220°C, and the reaction time is 2 hours. After the reaction, the solution is detected, and the degradation rate of cyanuric acid is 98.4%, and the yield of ammonia and carbon dioxide is 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com