Folded circular plastic sintering filtering device

A filter device, a circular technology, applied in the direction of dispersed particle filtration, transportation and packaging, dispersed particle separation, etc., can solve the problems of high pressure resistance, anti-shake, unfavorable service life, inability to replace filter bags, low pulse efficiency, etc., to achieve Avoid performance mismatch problems, excellent filtering effect, and reduce the effect of installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0037] In the present invention, the plastic composition with a mass ratio of 100:18:6 is mixed with polyurea formaldehyde and paraffin and then added to the injection molding machine, and the crude product of the outer layer tube and the inner layer tube are respectively prepared according to the processes of melting at 150 degrees and molding at 240 degrees. The rough reinforced parts; then put the rough outer tube and inner tube reinforced parts into boiling water for 1 hour, take them out, and let them dry naturally, which are the outer tube and inner tube reinforced parts; assembled with the base to form a discounted round The molded burning filter tube is used in the embodiment of the present invention, and the specific size can be designed through the mold.

[0038] The plastic composition is prepared by grafting γ-aminopropyltriethoxysilane, polyoxyethylene castor oil and maleic anhydride at 120 degrees for 2 hours, then adding dioctyl phthalate, and stirring for 30 min...

Embodiment 1

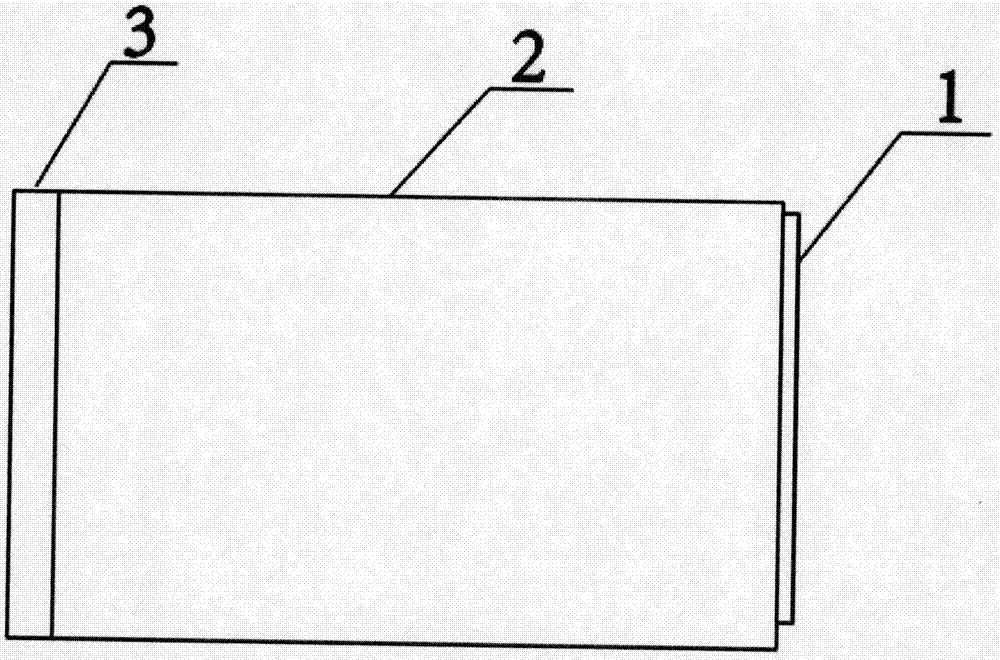

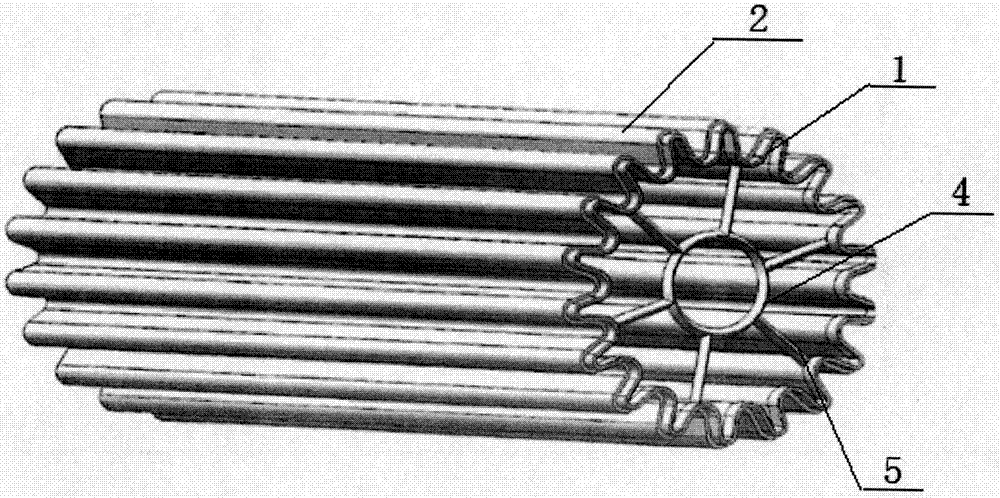

[0041] See attached Figure 1-2 , a discounted circular plastic-fired filter tube, comprising an inner tube 1, an outer tube 2, a reinforcement component, and a base 3; the cross-section of the inner tube and the outer tube have a similar structure, and are respectively installed on the base above; the inner tube is inserted into the outer tube, and the end face of the inner tube is higher than the end face of the outer tube; the reinforcing component includes a reinforcing ring 4 and a reinforcing rod 5; the reinforcing ring is located in the inner tube, and The reinforcement rod is connected to the inner tube, and the inner tube and the reinforcing part are integrally formed; the cross-section of the inner tube and the cross-section of the outer tube are gear-shaped structures; the tooth tops and tooth grooves of the gear-shaped structure are both Arc structure, in the arc structure, the arc angle of the top of the gear and the bottom of the tooth groove is 50 degrees, and t...

Embodiment 2

[0045]A discounted circular plastic-fired filter tube, comprising an inner tube, an outer tube, a reinforcing component, and a base; the cross section of the inner tube is similar in structure to that of the outer tube, and is installed on the base respectively; The inner tube is inserted into the outer tube, and the end face of the inner tube is higher than the end face of the outer tube; the reinforcing component includes a reinforcing ring and a reinforcing rod; the reinforcing ring is located in the inner tube, and passes through the reinforcing rod and the inner layer Tube connection, the inner tube and the reinforcing part are integrally formed; the cross section of the inner tube and the outer tube are both gear-shaped structures; In the structure, the arc angle of the top of the gear and the bottom of the tooth groove is 50 degrees, and the arc angle of the side wall is 100 degrees; the inner tube and the outer tube are not in contact; the reinforcing rod is a flat stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Ring stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com